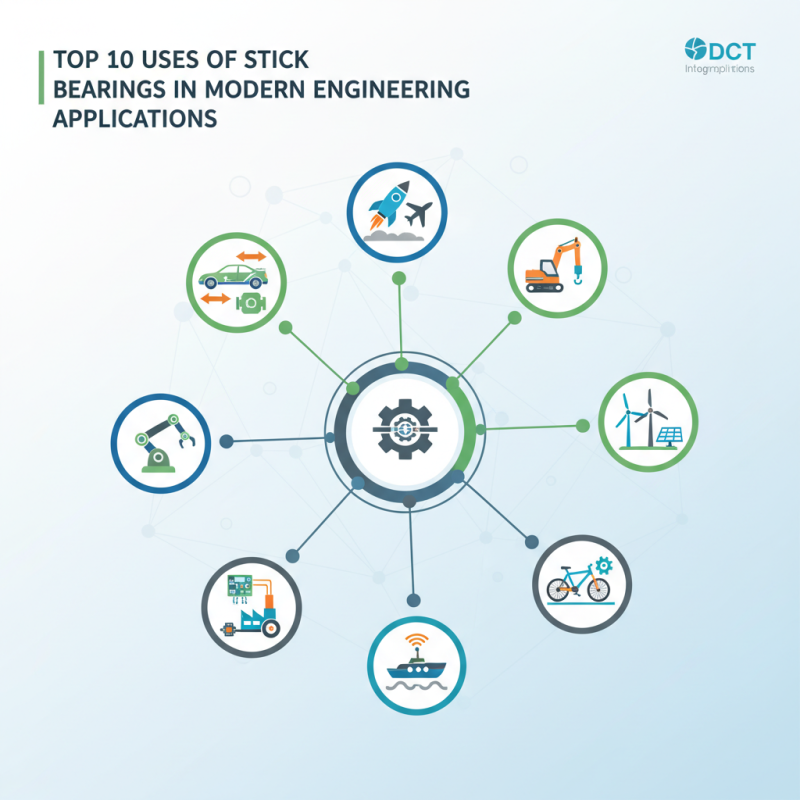

Top 10 Uses of Stick Bearings in Modern Engineering Applications?

In modern engineering, stick bearings have gained remarkable significance. These components provide essential support in various applications. As Dr. Emily Carter, an expert in tribology, states, "Stick bearings often optimize performance while minimizing friction." This highlights their vital role in enhancing machine efficiency.

Stick bearings are widely used in automotive, aerospace, and construction industries. They facilitate smooth motion in systems requiring low friction. However, their specific applications often challenge engineers to balance performance and durability. The materials used can influence the longevity of stick bearings.

Despite their advantages, stick bearings can sometimes fall short. In high-load scenarios, wear may occur faster than anticipated. Engineers must continuously assess their designs to improve these bearings' reliability. Ultimately, understanding stick bearings' role is crucial for future advancements in engineering.

Applications of Stick Bearings in Structural Engineering

Stick bearings play a pivotal role in structural engineering. They are essential where flexibility and support are required. These bearings manage loads effectively in various structures. They minimize friction while allowing relative movement between parts. This is crucial in bridges, buildings, and seismic applications.

In large infrastructures like bridges, stick bearings accommodate thermal expansion. They allow for the natural movement of materials without causing damage. The design is often straightforward but requires precise calculation. Engineers must consider load and movement carefully. A slight miscalculation can lead to significant issues.

Stick bearings also find use in tall buildings, particularly during wind events. They help dissipate forces that could compromise structural stability. However, their implementation is not without challenges. Maintenance is often overlooked, leading to potential failures. Regular inspections are important for long-term performance. Neglecting these aspects can result in serious consequences.

Stick Bearings in Transportation and Rail Systems

Stick bearings play a crucial role in transportation and rail systems. They provide support and reduce friction between moving components. This enhances the efficiency of vehicles and trains. Stick bearings have a unique design that allows for smooth movement. They are ideal for high-speed trains where every detail matters. Their ability to withstand heavy loads makes them essential in rail infrastructure.

In rail systems, stick bearings are often used in wheelsets. They help in guiding wheels along tracks while minimizing wear and tear. This means reduced maintenance and longer service life. When trains accelerate or decelerate, stick bearings help in maintaining stability. They absorb shocks and vibrations that can impact performance. Without them, rail systems would face significant challenges.

**Tips:** Regular inspection of stick bearings is key. Look for signs of wear early on. Proper lubrication can extend their life significantly. Consider environmental factors that might affect performance, like temperature and humidity. Adjustments may be necessary for optimal performance.

Top 10 Uses of Stick Bearings in Modern Engineering Applications

| Application Area | Key Features | Benefits | Typical Materials |

|---|---|---|---|

| Railway Vehicles | High load capacity, low friction | Enhanced durability, reduced maintenance | Polymer composites, steel |

| Bridges | Vibration dampening, load distribution | Improved stability, extended lifespan | Bronze, stainless steel |

| Automotive Components | Compact design, high strength | Weight reduction, fuel efficiency | POM (Polyoxymethylene), PTFE |

| Heavy Machinery | Shock absorption, high stability | Operational reliability, reduced wear | Nylon, high-carbon steel |

| Aerospace Industry | Lightweight, corrosion-resistant | Improved performance, safety | Titanium alloys, composite materials |

| Wind Turbines | Load capacity under dynamic forces | Increased energy efficiency, reduced noise | Self-lubricating composites, aluminum |

| Elevators | Smooth operation, quiet function | Enhanced user experience, reliability | Plastic composites, hardened steel |

| Marine Vessels | Water-resistant, anti-corrosive | Extended operational life, maintenance savings | Bronze, polymer |

| Construction Equipment | Heavy-duty, resistant to impact | Durability, uptime maximization | Steel, reinforced plastics |

Use of Stick Bearings in Aerospace Engineering

Stick bearings play a critical role in aerospace engineering. These components are designed to support loads while allowing limited motion. Their simplicity makes them attractive for various aerospace applications.

In aircraft, stick bearings often support moving parts, like flaps and ailerons. They enable smooth movement during aerodynamic adjustments. However, they can face wear and tear over time. In harsh environments, lubrication becomes a concern. Regular maintenance is necessary to ensure functionality, which can sometimes be overlooked.

Another application is in satellite systems. Stick bearings help stabilize equipment in orbit. They resist vibrations and shocks during launch. Yet, their performance in extreme conditions is still a topic for further research. Understanding their limitations could lead to better designs. Testing different materials might enhance their durability and efficiency in these demanding settings.

Top 10 Uses of Stick Bearings in Aerospace Engineering

Stick Bearings in Machinery and Mechanical Systems

Stick bearings play a vital role in modern machinery. They are often used in mechanical systems like motors and conveyor belts. These components help reduce friction and enhance efficiency. This is crucial for applications requiring smooth movement. The design allows for easy installation and removal, making maintenance simpler.

In many cases, stick bearings can wear out faster than expected. This results in unwanted downtime and costly repairs. Engineers must consider material choice and application environment carefully. A wrong selection can lead to failure. Many designs lack proper lubrication, leading to performance issues.

Despite some drawbacks, stick bearings offer unique advantages. They are lightweight and compact. This is beneficial in spaces where traditional bearings can't fit. Their simplicity can also lead to reduced manufacturing costs. However, relying solely on them might not always be wise. A blend of bearing types is often the best approach.

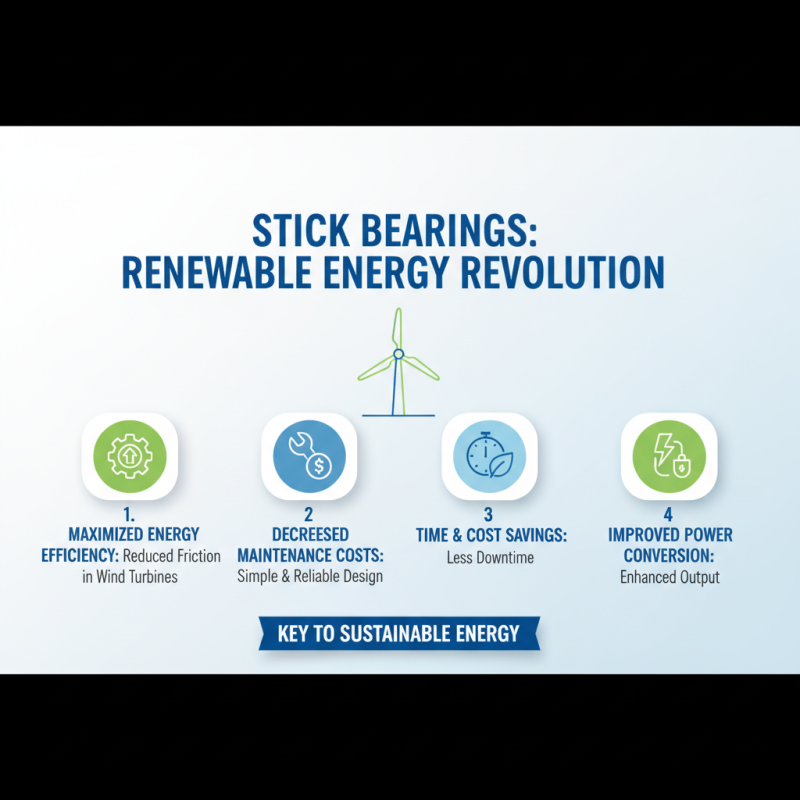

Innovative Uses of Stick Bearings in Renewable Energy Technologies

Stick bearings have emerged as pivotal components in renewable energy technologies. Their design maximizes energy efficiency in systems like wind turbines. The simplicity and reliability of stick bearings decrease maintenance costs. This is essential as maintenance can be both time-consuming and expensive. Wind turbine systems benefit significantly from reduced friction. This improves overall energy conversion efficiency.

In solar energy installations, stick bearings play a crucial role in trackers. They help maintain optimal panel angles throughout the day. Effective energy harvesting relies on precision. Stick bearings provide a compact solution for lightweight systems. However, their performance under extreme weather conditions is an area for improvement. Engineers need to assess durability and the impact of dust and moisture on operation.

Hydropower systems also utilize stick bearings for their longevity. Reduced wear leads to prolonged lifespan. Yet, there are limitations in high-load applications. Engineers must analyze material properties to find the best fit. Adapting designs to specific renewable energy needs remains a challenge. Each application offers unique requirements; finding balance is vital. This ongoing pursuit pushes innovation in stick bearing technologies.

Related Posts

-

Revolutionizing Motion: How Stick Bearings Enhance Efficiency in Modern Machinery

-

7 Essential Tips for Choosing the Right Pillar Bearing for Your Projects

-

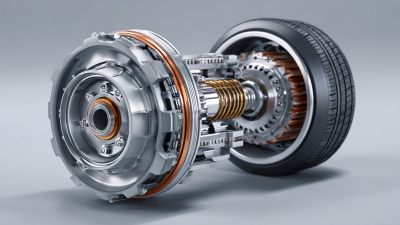

Unlocking Performance: The Essential Role of Tire Bearings in Modern Vehicle Dynamics

-

Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

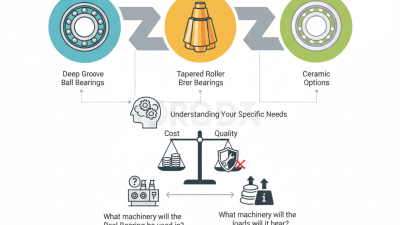

Best Real Bearing Types for Your Needs?