Top 10 Types of Tyre Bearings You Need to Know for Better Performance

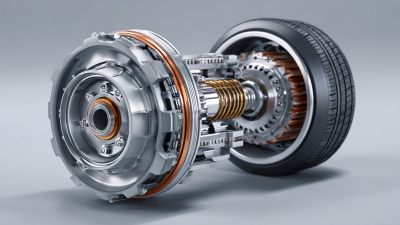

In the competitive landscape of the automotive industry, understanding the diverse types of tyre bearings is crucial for enhancing vehicle performance and safety. Research indicates that approximately 25% of vehicle rolling resistance can be attributed to tyre and bearing performance, underscoring the significance of precise selection and maintenance of these components. According to a recent report by the Global Automotive Components Manufacturers Association, advancements in tyre bearing technology alone can lead to a 15% increase in fuel efficiency, showcasing the vital role that tyre bearings play in modern vehicle design.

Expert in automotive engineering, Dr. Emily Johnson, highlights the intricate relationship between tyre bearings and overall driving experience, stating, "Choosing the right tyre bearing is fundamental to achieving optimal performance." Her insight reflects the industry's ongoing commitment to innovation and the quest for better performance metrics, illustrating that the selection process should not be taken lightly. With diverse consumer needs and evolving technological standards, exploring the top ten types of tyre bearings will equip both manufacturers and enthusiasts with the knowledge necessary to make informed decisions for enhanced vehicle performance.

Understanding Tyre Bearings: Basics and Functions

Tyre bearings play a crucial role in the performance and durability of vehicles. Essentially, these components help the wheels rotate smoothly while supporting the weight of the vehicle. They reduce friction between moving parts, which not only enhances fuel efficiency but also contributes to the overall safety of the vehicle. According to industry reports, vehicles fitted with high-quality bearings can achieve fuel savings of up to 8%, highlighting their significance in automotive engineering.

When considering tyre bearings, it’s essential to understand their different types, which can vary based on design and application. For example, tapered roller bearings and ball bearings are among the most commonly used types. Tapered bearings can handle both axial and radial loads, making them ideal for front wheels, whereas ball bearings are generally used in lighter loads. Maintaining optimal bearing conditions through regular inspections and greasing can significantly prolong their lifespan, ensuring that your vehicle performs at its best.

Tips: To maximize the performance of your tyre bearings, schedule regular check-ups and be on the lookout for signs of wear such as unusual noises or vibrations. Additionally, consider utilizing quality lubricants tailored for your specific bearing type, as these can significantly enhance operational efficiency and longevity. In summary, understanding tyre bearings and their functionality is pivotal for vehicle performance and maintenance.

Types of Tyre Bearings: Overview of Each Category

Tyre bearings are essential components that play a significant role in the performance and safety of vehicles. Understanding the various types of tyre bearings can help vehicle owners make informed decisions regarding maintenance and enhancements. The most common categories include roller bearings, which utilize cylindrical rollers to reduce friction and provide enhanced load capacity, and ball bearings, known for their ability to handle both radial and axial loads effectively while providing smooth operation.

Another important type is tapered roller bearings, which are particularly effective in accommodating heavy loads and are commonly used in truck and trailer axles. Additionally, spherical roller bearings offer the advantage of self-alignment, making them suitable for applications with misalignment issues. Lastly, thrust bearings are designed specifically for axial loads, ensuring stability and longevity in systems where such forces are prevalent. Each type of tyre bearing serves a unique function, contributing to the overall performance and durability of the vehicle, making it crucial for every vehicle owner to familiarize themselves with these components.

Top 10 Types of Tyre Bearings You Need to Know for Better Performance

Key Features: What to Look for in Tyre Bearings

When selecting tyre bearings, it is critical to consider several key features that enhance performance and longevity. One of the most important aspects is the material construction. High-quality bearings are typically made from steel or advanced composites that provide durability and resistance to wear. According to a 2022 industry report by the International Journal of Mechanical Engineering, using premium materials can improve bearing life by up to 30%. Additionally, the design of the bearing, such as whether it incorporates sealing or shielding, can significantly impact its efficiency and resistance to contamination, which is vital for maintaining peak performance over time.

Another essential consideration is the load rating of the tyre bearings. It directly affects the bearing's capability to support vehicle weight and the forces exerted during operation. Choosing bearings with a higher load rating than required can provide an extra margin of safety, ensuring that they perform well under pressure and in various driving conditions. The same industry report highlighted that optimal load distribution can lead to a 15% increase in bearing effectiveness, which correlates with overall vehicle stability and safety.

**Tip:** Always check the compatibility of bearings with your specific tyre models before making a purchase. This ensures that you select bearings that match the specifications needed for your vehicle. Regular maintenance and timely replacements based on wear indicators can further enhance the lifespan and performance of your tyre bearings.

Top 10 Types of Tyre Bearings You Need to Know for Better Performance

| Bearing Type | Key Features | Performance Benefits | Recommended Applications |

|---|---|---|---|

| Ball Bearing | Low friction, high speed | Enhanced speed and efficiency | Passenger vehicles |

| Roller Bearing | Higher load capacity, stable operation | Durability under heavy loads | Trucks and SUVs |

| Tapered Roller Bearing | Conical shape, excellent stability | Great performance under axial loads | Commercial vehicles |

| Spherical Roller Bearing | Self-aligning, withstand misalignment | Increased reliability | Off-road vehicles |

| Angular Contact Bearing | Multi-directional load support | Improved cornering stability | Performance cars |

| Deep Groove Bearing | Versatile, easy installation | Long life and low noise | General automotive applications |

| Needle Bearing | Compact, high radial load capacity | Space-saving design | Motorcycles and small vehicles |

| Thrust Bearing | Designed for axial loads | Effective load management | Heavy machinery |

| Magnetic Bearing | Non-contact operation | Reduced wear and tear | High-speed applications |

| Fluid Bearing | Fluid supports the load | Minimal friction | Industrial equipment |

Performance Impact: How Bearings Affect Tyre Efficiency

The performance of a tyre is heavily influenced by the type of bearings used. Bearings play a crucial role in reducing friction and wear, thereby enhancing the overall efficiency of a vehicle. According to industry reports, the right selection of bearings can improve fuel efficiency by up to 5%. This is primarily because high-quality bearings minimize rolling resistance, which directly impacts how smoothly a vehicle operates. When bearings are worn or of lower quality, the vehicle experiences increased drag, leading to higher fuel consumption and reduced performance.

Moreover, research indicates that the material and design of bearings can significantly affect tyre longevity and performance stability. For instance, ceramic bearings are reported to offer enhanced performance in high-load scenarios compared to traditional steel bearings. In a comparative study published by the International Federation of Automotive Engineering Societies, it was noted that vehicles equipped with advanced bearings could extend tyre life by approximately 15%. This not only means reduced replacement costs but also less environmental impact due to fewer discarded tyres. Understanding the intricacies of tyre bearings can help vehicle owners maximize efficiency, performance, and sustainability on the road.

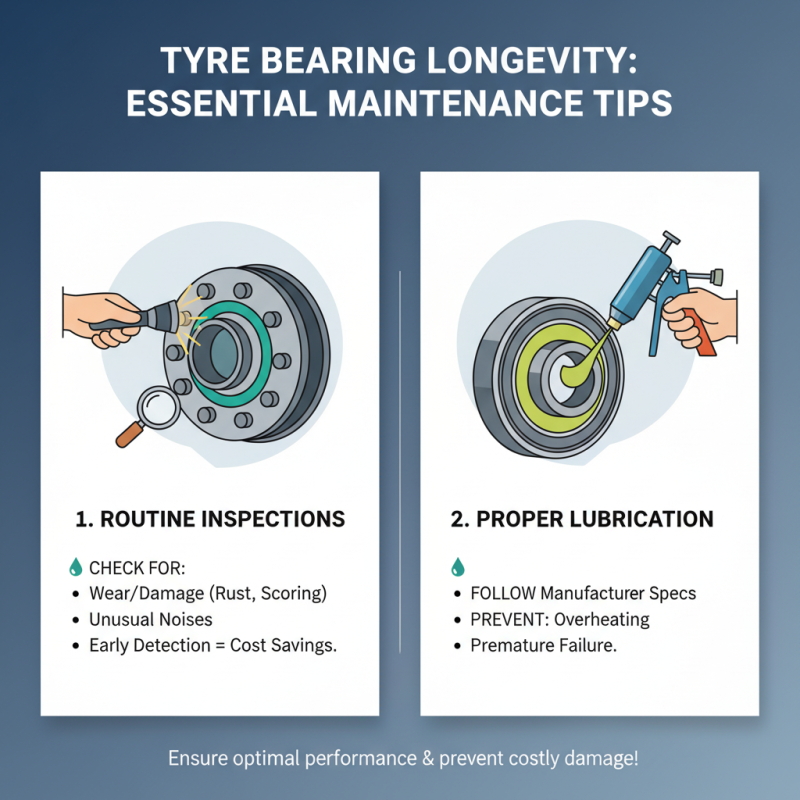

Maintenance Tips: Extending the Life of Your Tyre Bearings

To ensure the longevity and optimal performance of your tyre bearings, regular maintenance is essential. One of the most crucial maintenance tips is to conduct routine inspections. Check for signs of wear or damage, such as rust, scoring, or unusual noises when in motion. Addressing these issues early can prevent more extensive damage and costly replacements down the line. Additionally, ensure that bearings are properly lubricated according to the manufacturer’s specifications, as insufficient lubrication can lead to overheating and premature failure.

Another important maintenance practice is to keep your tyre bearings clean. Dirt and debris can accumulate over time, impacting their performance. Regular cleaning can be achieved by removing the bearings and using a suitable solvent to eliminate contaminants, followed by applying the correct lubricant. Furthermore, it's essential to monitor the alignment and fit of your bearings during installation, as improper positioning can lead to uneven wear and decreased efficiency. By prioritizing these maintenance steps, you can significantly extend the life of your tyre bearings and enhance overall performance.

Related Posts

-

Unlocking Performance: The Essential Role of Tire Bearings in Modern Vehicle Dynamics

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

The Critical Role of Hub Bearings in Enhancing Vehicle Safety and Performance Vital Statistics You Should Know

-

Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

-

How to Optimize Your Projects with Tape Bearing Solutions

-

How to Choose the Right Pillar Bearing for Your Industrial Needs