Top 10 Truck Bearings to Enhance Your Vehicle Performance?

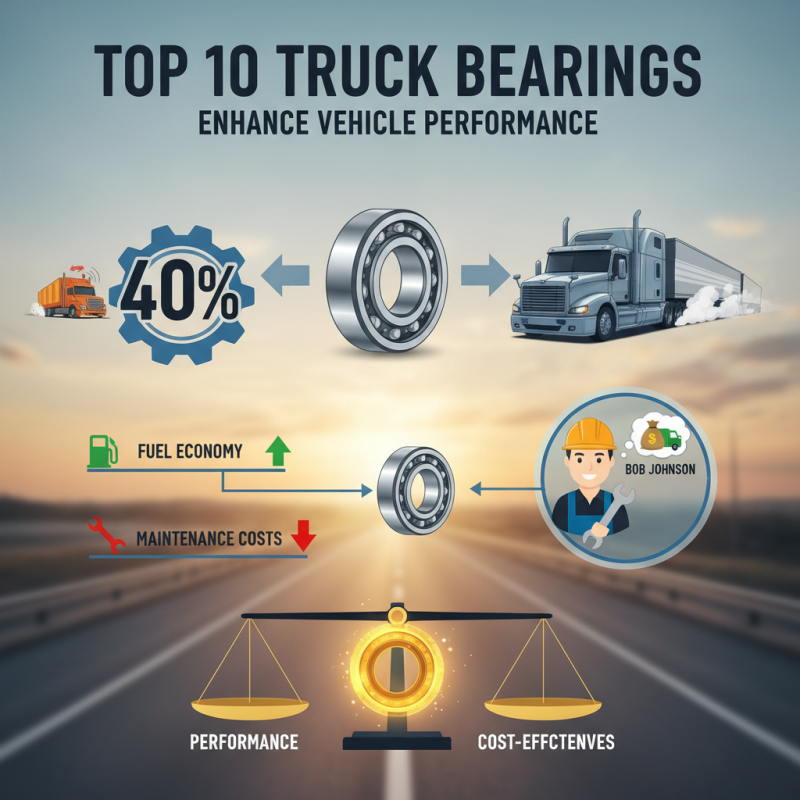

In the competitive world of trucking, performance matters. One crucial component that often gets overlooked is Truck Bearings. According to a recent report by the National Institute for Truck and Bus Research, up to 40% of vehicle inefficiencies stem from subpar bearings. These small yet essential parts can significantly influence a truck's overall efficiency and longevity.

Expert Bob Johnson, a prominent figure in the Truck Bearings industry, emphasizes, "Investing in quality bearings is investing in your truck's future." This perspective highlights the vital role bearings play in reducing friction and enabling smoother rides. For every mile covered, the durability of Truck Bearings directly impacts both fuel economy and maintenance costs.

It's important to recognize that not all Truck Bearings are created equal. Poor selections can lead to premature wear and tear, resulting in costly repairs. Striking the right balance between performance and cost-effectiveness poses a challenge to many truck owners. Enhancing your vehicle's performance begins with understanding the significance of these components and making informed decisions.

Top 10 Truck Bearings: Overview of Importance for Vehicle Performance

When it comes to truck performance, selecting the right bearings is crucial. Quality bearings can reduce friction and increase overall efficiency. This will not only improve your driving experience but also extend the lifespan of your vehicle. You might wonder, what makes a bearing effective? It's all about material and design.

Bearings are often overlooked. Many drivers focus on flashy upgrades. However, high-quality bearings enhance stability and support the weight of your truck. A small change in bearing type can lead to noticeable performance improvements.

Tips for selecting bearings: Always check load ratings. Understand the types of loads your truck will carry. Research material durability, as it affects wear and maintenance costs. Do not forget to consider environmental factors. Bearings exposed to moisture or dirt require extra care.

Investing in the right bearings can seem daunting. It might feel overwhelming with so many options. However, taking the time to research pays off. Make informed decisions. Your truck will run smoother and serve you better. Remember, performance is in the details, even the small ones.

Top 10 Truck Bearings to Enhance Your Vehicle Performance

Understanding Different Types of Truck Bearings and Their Functions

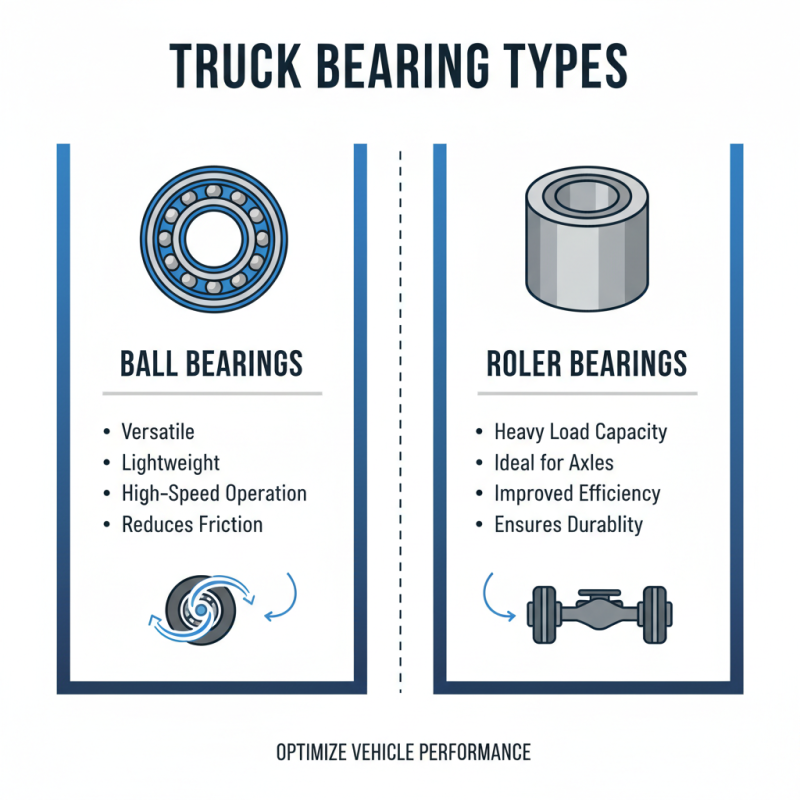

Understanding different types of truck bearings is crucial for optimizing vehicle performance. Bearings play a pivotal role in reducing friction, improving efficiency, and ensuring long-term durability. There are various types of truck bearings, each serving specific functions. For example, ball bearings are known for their versatility. They are lightweight and operate well at high speeds. In contrast, roller bearings handle heavier loads better, making them ideal for truck axles.

Recent industry reports indicate that about 30% of bearing failures are due to inadequate lubrication. This highlights the importance of selecting the right bearing type for your specific needs and maintaining it properly. For example, tapered roller bearings, used in wheel hubs, provide excellent load distribution. However, they require precise adjustments for optimal performance.

Additionally, ceramic bearings are gaining popularity in the trucking industry. They offer lower friction and greater resistance to wear and tear. However, they can be more fragile than their steel counterparts. This raises important questions about their suitability depending on operational conditions. Each type of bearing has its advantages and disadvantages, which need careful consideration to truly enhance truck performance.

Key Features to Look for When Choosing Truck Bearings

When selecting truck bearings, it’s crucial to consider key features. The material of the bearings plays a significant role. High-quality steel or ceramic materials often resist wear better. This can enhance durability and overall performance.

Another important feature is the bearing type. Roller bearings tend to handle heavy loads effectively. Ball bearings, on the other hand, provide smoother motion. Understanding the specific needs of your truck is essential.

Additionally, pay attention to the size and fit. A mismatched bearing can lead to system failures. Regular maintenance is also vital for longevity. Sometimes, even minor adjustments can dramatically improve functionality. Consider these factors to optimize your truck’s performance.

Top 10 Truck Bearings to Enhance Your Vehicle Performance

| Bearing Type | Load Capacity (lbs) | Material | Sealing Type | Temperature Range (°F) |

|---|---|---|---|---|

| Ball Bearing | 6,600 | Steel | Sealed | -40 to 200 |

| Tapered Roller Bearing | 9,000 | Steel | Open | -30 to 220 |

| Spherical Roller Bearing | 10,500 | Alloy Steel | Sealed | -40 to 230 |

| Needle Bearing | 5,000 | Chrome Steel | Open | -30 to 185 |

| Deep Groove Ball Bearing | 8,000 | Stainless Steel | Sealed | -40 to 250 |

| Angular Contact Bearing | 7,500 | Carbon Steel | Open | -20 to 200 |

| Thrust Bearing | 11,000 | Bronze | Open | -40 to 300 |

| Plain Bearing | 4,500 | Polymer | Open | -20 to 180 |

| Self-Aligning Bearing | 9,200 | Alloy Steel | Sealed | -40 to 220 |

| Ceramic Bearing | 12,000 | Silicon Nitride | Open | -40 to 400 |

Installation and Maintenance Tips for Optimal Truck Bearing Performance

Maintaining optimal truck bearing performance is essential for enhancing vehicle efficiency. Regular inspections help catch issues before they escalate. According to a recent industry report, about 30% of bearing failures are due to insufficient maintenance. Keeping bearings clean and well-lubricated is crucial.

Tips for maintenance:

- Regularly check for any signs of wear or unusual sounds. Addressing these early can prevent costly repairs.

- Keep bearings free from dirt and debris. Simple cleaning with a soft cloth can make a big difference.

- Ensure the right lubricant is used. Using improper lubricants leads to failure.

Installation also plays a significant role. Proper techniques can increase performance. It's reported that misalignment can reduce bearing life by up to 50%. Use a torque wrench for accurate installation.

Another tip: always follow manufacturer specifications. Ignoring these can result in mismatched components, leading to further issues. Regularly updating training for installation staff is beneficial. A well-informed team responds faster to potential problems.

Comparative Analysis of the Top 10 Truck Bearings on the Market

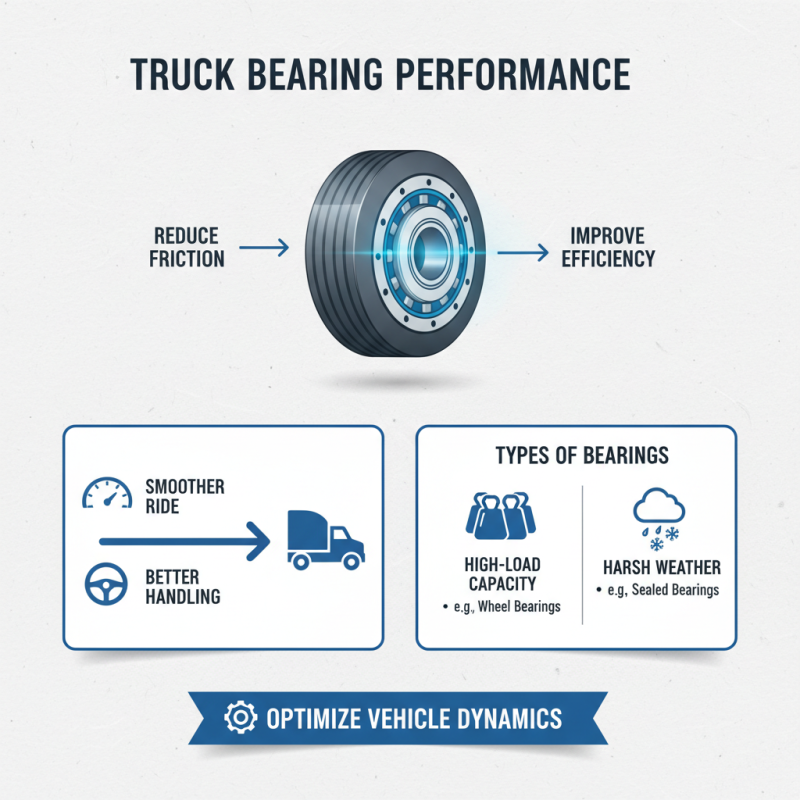

When it comes to truck performance, bearings play a crucial role. They reduce friction and improve efficiency, which can enhance overall vehicle dynamics. A good bearing can provide a smoother ride and better handling. The market offers various truck bearings, each with unique specifications. Some excel in high load capacities, while others perform better in harsh weather conditions.

However, choosing the right bearing is often a trial-and-error process. Many truck owners report dissatisfaction after selecting bearings that do not meet their needs. Some may find that high-performance options are not always compatible with their vehicle types. It's essential to examine materials and design features. Factors like seal types and internal clearances can greatly affect performance.

Moreover, price does not always equate to quality. Some lower-priced bearings could outperform premium options. Evaluating user reviews and expert recommendations can shed light on real-world performance. You might encounter bearings that fail unexpectedly. This causes frustration and unnecessary maintenance costs. Understanding your vehicle's specific requirements is vital before making a purchase.

Related Posts

-

10 Best Truck Bearings for Optimal Performance in 2026?

-

Top Tips for Choosing Truck Bearings to Enhance Performance and Longevity

-

10 Best Truck Bearings for Optimal Performance and Durability

-

Understanding Pillow Bearings: Benefits, Applications, and Choosing the Right Type in 2025

-

Revolutionizing Motion: How Stick Bearings Enhance Efficiency in Modern Machinery

-

2026 Best Tire Bearing Options and Tips for Selection?