2026 Top Needle Bearings Options and Their Benefits?

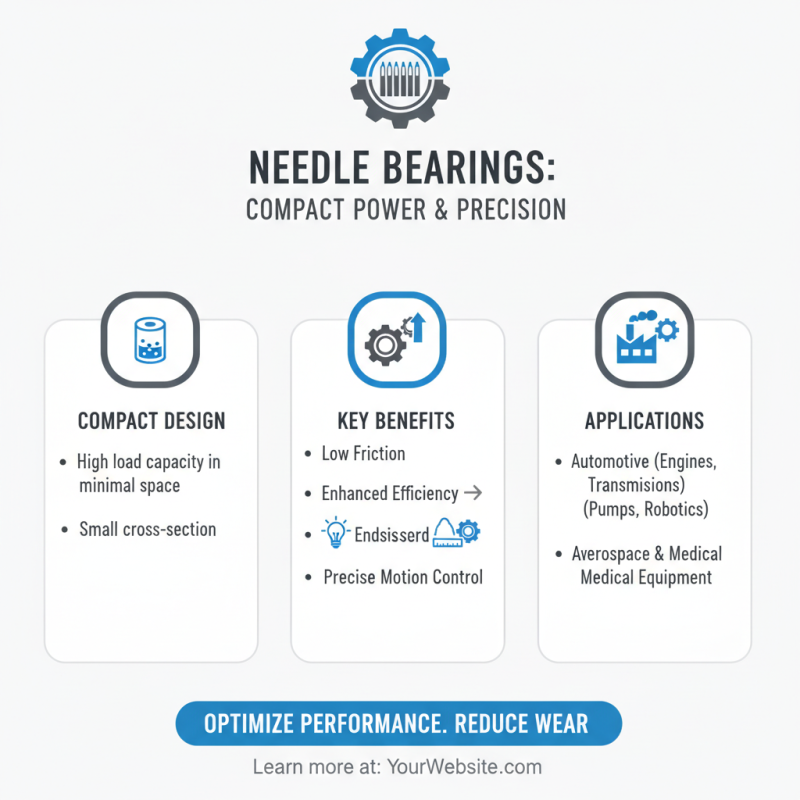

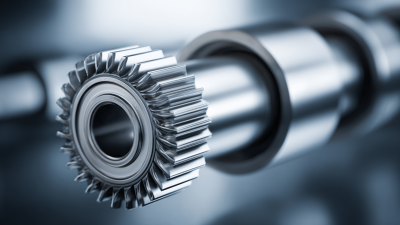

In the world of machinery, needle bearings play a crucial role. These small, cylindrical components have a high load-bearing capacity. They are used in various applications, from automotive to industrial equipment. Needle bearings excel in confined spaces, making them a popular choice. Their design allows for smooth rotation and minimizes friction, enhancing overall efficiency.

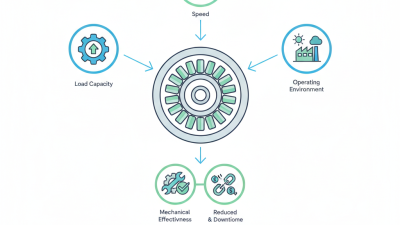

Choosing the right needle bearings in 2026 requires careful consideration. Not all options offer the same benefits or durability. Users often overlook the importance of material and design specifics. Quality needle bearings provide substantial long-term advantages. However, improper selection can lead to mechanical failures. It's essential to evaluate options critically and reflect on past experiences.

Understanding the benefits of various needle bearings can be enlightening. Each type serves a unique purpose, catering to specific industries. This discussion will illuminate best practices. We may find some common oversights in selection. By exploring these options, one can enhance performance and reliability in machinery.

2026 Needle Bearing Overview: Types and Applications

Needle bearings are vital components in various industrial applications. They consist of cylindrical rollers and allow for high load capacities while occupying minimal space. The global needle bearing market is projected to grow substantially, with a report estimating a CAGR of 5.1% from 2022 to 2028. Their applications range from automotive to aerospace, making them quite versatile.

There are several types of needle bearings, including drawn cup needles, machined needle bearings, and thrust needle bearings. Each type serves specific functions and comes with unique benefits. For example, drawn cup needle bearings excel in applications where space is limited. They are lightweight and have a low profile. However, they can be prone to misalignment if not installed properly, indicating a need for careful assembly.

In manufacturing, using needle bearings can improve efficiency and reduce wear. Many industries experience a 20% increase in performance when switching to these bearings. However, they also require regular maintenance. Neglecting to maintain needle bearings can lead to premature failure, which may cause unexpected downtime. It’s critical to understand both the strengths and weaknesses of these components for effective operation.

Key Features of Top Needle Bearings for Industrial Uses

Needle bearings play a crucial role in various industrial applications. They are compact yet powerful. The design allows for effective load support while maintaining low friction levels. This feature is essential for enhancing the efficiency of machinery. Many machines rely on precise motion control, and needle bearings deliver that.

One key feature is their high load capacity. This allows manufacturers to design smaller and lighter machines without sacrificing performance. Needle bearings are also known for their ability to handle high-speed operations. They offer consistent performance under demanding conditions.

However, choosing the right needle bearing can be challenging. It's important to consider factors like size, material, and lubrication needs. Some users may overlook maintenance, leading to premature failure. Regular checks can help prevent costly downtimes and ensure longevity. Understanding these features allows engineers to maximize the benefits of needle bearings in practical situations.

Comparative Analysis of Leading Needle Bearings Brands

When examining needle bearings, several key players emerge in the industry, each offering unique advantages. Needle bearings are prized for their ability to support high loads with minimal radial space. According to recent industry data, this market is expected to grow by 4.5% annually through 2026. This growth is driven by increased demand in automotive and industrial applications.

A comparative analysis reveals that some brands exhibit superior wear resistance. These improvements stem from advanced material treatments. However, it's essential to note that some bearings may not perform well in extreme temperatures. Data indicates that around 25% of users experience failures in high-heat environments. This raises questions about the reliability of certain brands during critical operations.

Additionally, while some brands claim high precision, there can be inconsistencies in manufacturing. Research shows that nearly 15% of needle bearings do not meet specified tolerances. It's crucial to scrutinize manufacturing processes and quality control. Buyers should consider these factors when choosing needle bearings, as they play a significant role in overall performance and durability.

2026 Top Needle Bearings Options and Their Benefits

Benefits of Using Needle Bearings in Machinery and Equipment

Needle bearings are essential in many machines and equipment. Their unique design allows them to carry load efficiently, even in tight spaces. These bearings use long, thin rollers, which reduce friction. This design results in smooth operation and increases longevity.

Using needle bearings can improve machinery performance. They help minimize wear and tear, leading to less downtime. In heavy equipment, their ability to handle radial loads is crucial. Moreover, they can maintain high speeds without overheating. However, improper installation can lead to issues. It's vital to ensure they fit correctly for optimal function.

Maintaining needle bearings is not as straightforward as it seems. Regular checks are necessary to prevent failure. Dirt and contaminants can lead to problems, so proper lubrication is key. Some users overlook this aspect, which can compromise the benefits. A proactive approach to maintenance can enhance performance significantly. Ultimately, needle bearings can be a game changer in machinery applications.

2026 Top Needle Bearings Options and Their Benefits

| Bearing Type | Load Capacity (N) | Speed (RPM) | Material | Benefits |

|---|---|---|---|---|

| Drawn Cup Needle Bearing | 1500 | 9000 | Steel | Compact design, high load capacity |

| Thrust Needle Bearing | 1200 | 8000 | Stainless Steel | Excellent thrust load support, corrosion resistance |

| Cylindrical Needle Bearing | 1800 | 6000 | Bronze | High durability, suitable for harsh environments |

| Needle Roller Bearing | 2000 | 7000 | Carbon Steel | Low friction, high load capacity |

| Heavy Duty Needle Bearing | 2500 | 5000 | Alloy Steel | Superior load handling, longevity under stress |

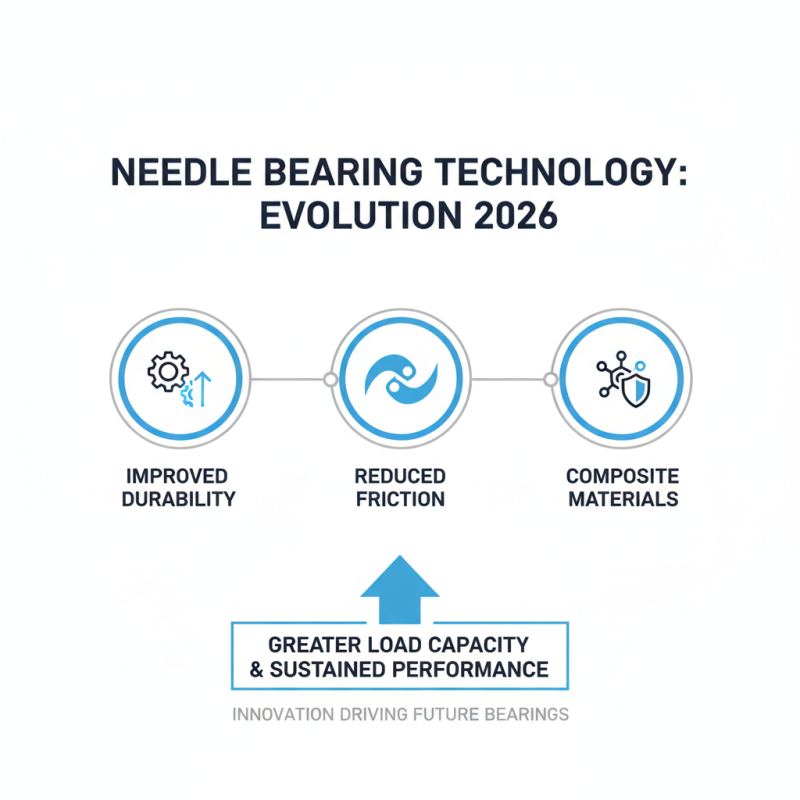

Emerging Trends in Needle Bearing Technology for 2026

Needle bearing technology is rapidly evolving as we approach 2026. One significant trend is the shift towards materials that offer improved durability and reduced friction. Innovations in composite materials are showing promise. These new materials can withstand greater loads while maintaining performance.

Another emerging trend is the integration of smart technology within needle bearings. Sensors that monitor performance can provide real-time data. This capability allows for proactive maintenance and reduces unexpected failures. The challenge lies in ensuring these sensors remain reliable in various environments.

Many manufacturers are exploring new designs that improve load distribution. Enhanced geometries are being tested to maximize efficiency. However, there is still room for improvement in balancing these designs with cost-effectiveness. Adapting to customer needs can sometimes lead to overlooking essential details. Each advancement needs careful consideration to ensure overall effectiveness.

Related Posts

-

Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

-

2026 How to Choose the Right Needle Bearings for Your Projects?

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

2025 Top Needle Bearing Trends: What You Need to Know for Optimal Performance

-

Top Benefits of Using Needle Rollers in Modern Machinery Applications

-

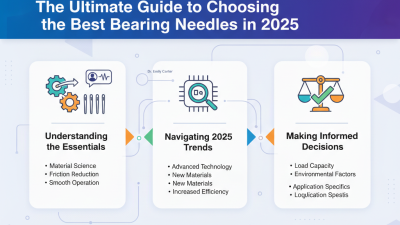

The Ultimate Guide to Choosing the Best Bearing Needles in 2025