Top 10 Deep Bearing Types for Optimal Performance in Various Applications

The world of engineering and manufacturing has witnessed significant advancements in bearing technology, with "Deep Bearings" emerging as a critical component in ensuring optimal performance across various applications. As industries strive for efficiency and reliability, the importance of selecting the appropriate bearing type cannot be overstated. According to a recent report by the Global Bearings Market Analysis, the demand for deep groove ball bearings alone is projected to reach over $12 billion by 2025, indicating a robust growth trajectory driven by their versatile applications.

Industry expert Dr. Alex Johnson, a leading authority in bearing technology, emphasizes the essential role of deep bearings in machinery performance, stating, "The right deep bearing can dramatically enhance operational efficiency while reducing maintenance costs." His insights reflect a growing recognition of the complexities involved in bearing selection, further underscoring the necessity for engineers to stay informed about the latest advancements and types of deep bearings available in the market.

In this article, we delve into the top 10 deep bearing types that offer optimal performance in a variety of applications, exploring their unique features, benefits, and suitability for specific operating conditions. Such knowledge is invaluable for professionals looking to enhance productivity and longevity in their mechanical systems.

Understanding Deep Bearings: Definition and Importance

Deep bearings play a crucial role in various mechanical systems, serving as key components that facilitate smooth movement between rotating or moving parts. Unlike standard bearings, deep bearings are designed with a greater depth in the raceway. This unique feature enables them to support higher loads and tolerate misalignments more effectively, making them indispensable in applications that demand optimal performance. Understanding the design and function of deep bearings is essential for engineers and technicians, as it directly influences the reliability and efficiency of machinery.

The importance of deep bearings extends beyond their structural capabilities. These bearings are integral to minimizing friction, reducing wear, and extending the lifespan of machinery components. In applications where precision is paramount, such as in robotics or aerospace, the right type of deep bearing can significantly enhance both speed and accuracy. Additionally, their ability to handle high radial and axial loads makes deep bearings suitable for a wide range of industries, from automotive to manufacturing. As technology advances, the demand for innovative bearing solutions continues to grow, emphasizing the need for ongoing research and development in this pivotal area of engineering.

Top 10 Deep Bearing Types for Optimal Performance

This chart shows the performance ratings for various types of deep bearings, essential for optimal functionality in diverse applications. Ratings are based on factors such as load capacity, friction, and operational efficiency.

Factors Influencing Deep Bearing Performance in Different Applications

The performance of deep bearings in various applications is influenced by several critical factors, each playing a significant role in their efficiency and longevity. One key factor is the load capacity; as reported by the International Journal of Engineering Research and Technology, deep bearings must be selected based on their ability to withstand specific load conditions without excessive deformation. This is particularly crucial in heavy machinery and automotive applications, where bearing failure can lead to costly downtimes and repairs.

Another significant factor is the operating environment. According to a study published by the Journal of Tribology, environmental conditions such as temperature, humidity, and exposure to contaminants can dramatically affect the performance of deep bearings. For instance, in high-temperature applications, specialized lubricants are often required to maintain a protective film between surfaces, preventing premature wear and tear. Additionally, the choice of material for both the bearings and their housing can significantly enhance resistance to corrosion and fatigue, which, as industry reports suggest, can extend the service life of deep bearings considerably.

Finally, lubrication plays a crucial role in the performance of deep bearings. The appropriate type and quality of lubricant can reduce friction, prevent overheating, and enhance load distribution. A comprehensive analysis by the Lubrication Engineers Association indicates that improper lubrication can decrease bearing efficiency by up to 30%. Therefore, selecting the right lubrication system tailored to the specific application and operational conditions is paramount to achieve optimal bearing performance.

Top 10 Deep Bearing Types for Optimal Performance in Various Applications

| Bearing Type | Material | Load Capacity (N) | Speed Rating (RPM) | Application |

|---|---|---|---|---|

| Deep Groove Ball Bearing | Chrome Steel | 2000 | 12000 | Electric Motors |

| Angular Contact Bearing | Ceramic/Steel | 3000 | 18000 | Machine Tool |

| Spherical Roller Bearing | Alloy Steel | 15000 | 9000 | Heavy Machinery |

| Tapered Roller Bearing | Steel | 10000 | 8000 | Automotive |

| Needle Bearing | Stainless Steel | 5000 | 20000 | Compact Spaces |

| Self-Aligning Ball Bearing | Chrome Steel | 12000 | 10000 | Agricultural Equipment |

| Thrust Ball Bearing | Chrome Steel | 4000 | 6000 | Vertical Loads |

| Floating Bearing | Brass | 6000 | 7000 | Railway Applications |

| Cartridge Bearing | Composite | 3500 | 12000 | Appliance Motors |

| Deep Groove Angular Contact Bearing | Hybrid Ceramic | 8000 | 15000 | High-Speed Equipment |

Top 10 Deep Bearing Types and Their Unique Features

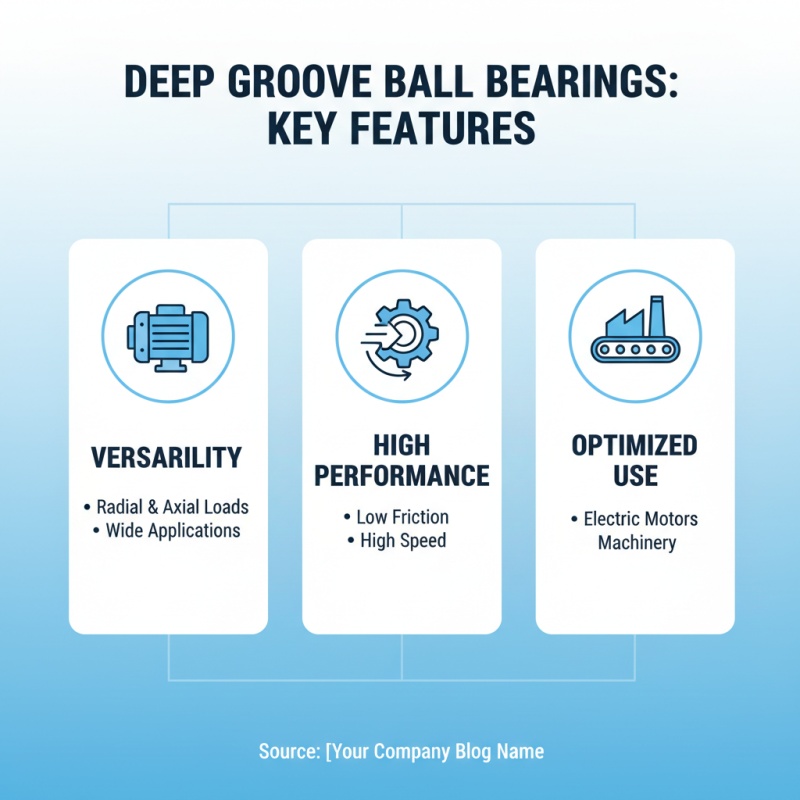

When it comes to selecting deep bearings, understanding their unique features is crucial for optimizing performance across various applications. Deep groove ball bearings are amongst the most popular due to their versatility and ability to accommodate both radial and axial loads. They exhibit low friction and high-speed capabilities, making them ideal for electric motors and other high-speed machinery.

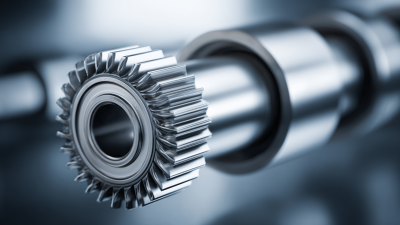

Another notable type is the angular contact ball bearing, which is designed to handle higher axial loads, making them perfect for applications like gearboxes and pumps. Their specialized design allows for precise adjustments, enhancing efficiency in performance. Additionally, deep tapered roller bearings offer the advantage of distributing loads across a wider contact area, improving durability and stability, especially in heavy machinery.

**Tips**: When choosing the right deep bearing type, consider the specific load requirements and operational conditions of your equipment. It's also beneficial to consult technical specifications and performance ratings that align with your application needs. Proper installation and regular maintenance can significantly extend the lifespan of your bearings, ensuring optimal performance over time.

Applications of Deep Bearings Across Various Industries

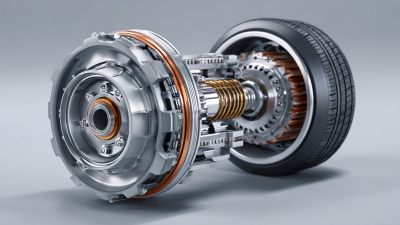

Deep bearings play a critical role across various industries, enhancing the performance and efficiency of machinery and equipment. In applications such as automotive manufacturing and aerospace engineering, deep bearings provide superior load-carrying capacity and durability, significantly reducing maintenance costs. According to a report by the International Journal of Advanced Manufacturing Technology, the use of high-quality deep bearings can enhance the lifespan of rotating equipment by up to 50%, while also improving overall operational reliability.

In the energy sector, particularly in wind turbine applications, deep bearings are essential for ensuring optimal rotor performance. The rotor bearing demand is projected to grow at a CAGR of 5.1% through 2025, driven by advancements in turbine technology and increased investments in renewable energy. Properly selected deep bearings can facilitate smoother operation, minimizing friction and wear, which is pivotal in reducing downtime.

Tips: When selecting deep bearings for specific applications, consider factors such as load requirements, environmental conditions, and lubrication options. Additionally, regular maintenance routines should include inspections of bearing wear to ensure longevity and reliability under high-stress conditions.

Maintenance Practices for Enhancing Deep Bearing Longevity

When it comes to enhancing the longevity of deep bearings, implementing effective maintenance practices is crucial. Regular inspections are essential; checking for wear and tear can help identify potential issues before they turn into major problems. It's important to clean the bearing surfaces to prevent the buildup of dirt and grease, which can lead to premature failure. Proper lubrication also plays a vital role—using the right lubricant and maintaining optimal levels can significantly reduce friction, extending the service life of deep bearings.

Tips for maintaining deep bearings include monitoring operating temperatures, as overheating can indicate inadequate lubrication or excessive load. Another best practice is to ensure that bearings are properly housed, as misalignment can cause uneven wear and damage. Additionally, creating a maintenance schedule based on operating hours can help adhere to regular checks and replacements, ensuring that your bearings perform at their best.

To further enhance bearing longevity, operators should consider environmental factors. Keeping the bearing area clean and free from contaminants like dust and moisture can prevent corrosion and degradation. Implementing vibration analysis can also assist in early detection of wear patterns, allowing for timely interventions and repairs. Through these diligent maintenance practices, you can optimize performance and prolong the life of deep bearings across various applications.

Related Posts

-

Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

-

How to Optimize Your Projects with Tape Bearing Solutions

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

Unlocking Performance: The Essential Role of Tire Bearings in Modern Vehicle Dynamics

-

What is Tapped Bearing and How Does It Enhance Mechanical Performance

-

7 Essential Tips for Choosing the Best Pillar Bearing for Your Needs