What is Tapped Bearing and How Does It Enhance Mechanical Performance

In the ever-evolving landscape of mechanical engineering, the introduction of innovative components remains pivotal for enhancing performance and efficiency. One such advancement is the Tapped Bearing, a specialized component that significantly improves load distribution and minimizes friction in rotating systems. According to a recent report by the Global Bearings Market Association, the demand for advanced bearing technologies is projected to grow at a compound annual growth rate (CAGR) of 7.5% through 2025, driven largely by increasing applications in automotive and aerospace industries.

Dr. Emily Harrison, a leading expert in bearing technology, emphasizes the importance of Tapped Bearings in modern engineering: "Tapped Bearings not only ensure structural integrity but also optimize energy consumption, making them indispensable in today’s high-demand environments." As manufacturers continue to seek ways to enhance mechanical performance, the integration of Tapped Bearings into various applications will undoubtedly play a crucial role in achieving greater efficiency and longevity of machinery. This article delves into the mechanics of Tapped Bearings and explores their implications for the future of engineering solutions.

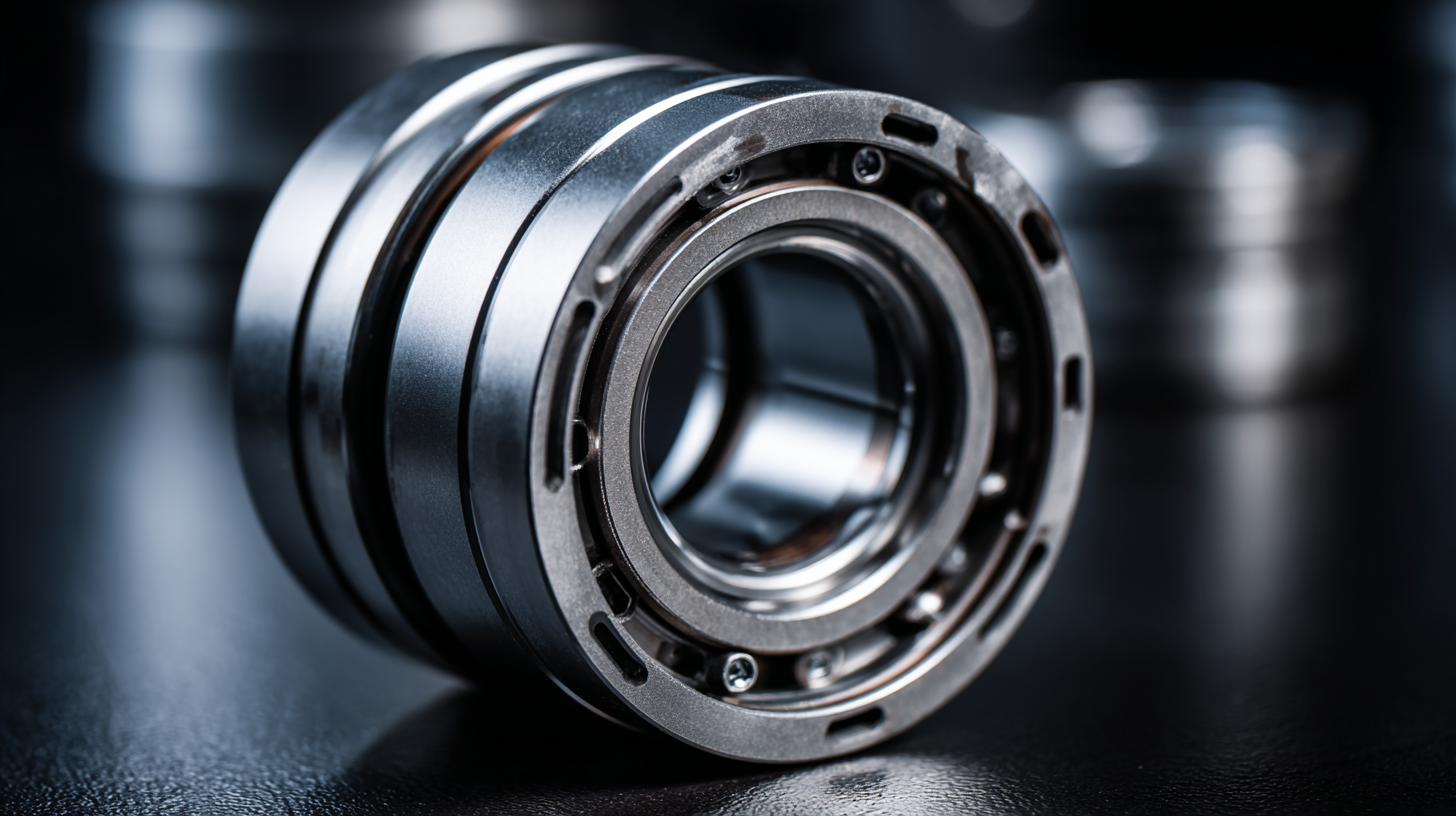

Exploring the Definition and Functionality of Tapped Bearings

Tapped bearings are mechanical components designed to facilitate smooth rotational or linear movement within a machine. Unlike traditional bearings, tapped bearings incorporate threaded holes that allow for easy attachment and alignment. This feature simplifies installation and maintenance, making them valuable in environments where adjustments are frequently required. The threading also enables the bearing to be securely fastened to its housing, reducing the risk of misalignment during operation.

Functionally, tapped bearings enhance mechanical performance by providing greater stability and precision. Their design minimizes friction between moving parts, which leads to less wear and tear over time. Additionally, tapped bearings can accommodate a variety of load conditions, making them versatile for applications ranging from automotive systems to industrial machinery. The ability to adjust the load alignment through the threaded interface further contributes to their effectiveness, allowing for precise control over the mechanical functionality of the entire system.

Key Advantages of Tapped Bearings Over Conventional Bearings

Tapped bearings are becoming increasingly popular in various industrial applications due to their unique advantages over conventional bearings. One significant advantage is their enhanced load capacity. According to a report by the American Society of Mechanical Engineers (ASME), tapped bearings can handle up to 30% more load in similar size comparisons, making them ideal for heavy-duty machinery where stress levels are high.

Moreover, tapped bearings often feature advanced design elements that reduce friction and wear. A study published in the Journal of Mechanical Engineering found that tapped bearings exhibit a 15% reduction in friction coefficient compared to traditional bearings. This reduction significantly translates to improved energy efficiency, leading to lower operational costs. As industries strive for sustainability, the application of tapped bearings aligns with these goals by minimizing energy waste and enhancing overall mechanical performance. Their ability to maintain effectiveness under extreme conditions further solidifies their position as a superior choice in modern engineering applications.

Applications of Tapped Bearings in Various Mechanical Systems

Tapped bearings are integral components that significantly enhance the mechanical performance of various systems. Their design allows for better load distribution, reduced friction, and improved durability. These bearings are particularly beneficial in applications where high precision and reliability are essential, such as in automotive, aerospace, and industrial machinery. They allow for simpler assembly processes and can accommodate slight misalignments, making them essential in dynamic environments.

In contemporary applications, tapped bearings find their place in innovative mechanical systems, including those used in medical technologies. A relevant example is the ongoing research into the mechanical properties of biodegradable and metallic systems in oral and maxillofacial surgery. The integration of tapped bearings in these systems could provide improved stability and performance during surgical procedures, potentially leading to enhanced patient outcomes. As industries continue to explore advanced materials and designs, the role of tapped bearings will likely expand, optimizing efficiency in both mechanical and biomedical applications.

Mechanisms Through Which Tapped Bearings Enhance Performance

Tapped bearings have emerged as a pivotal advancement in mechanical performance, particularly in reducing friction and enhancing load distribution. According to a report from the American Society of Mechanical Engineers (ASME), tapped bearings can decrease energy losses by up to 30% compared to traditional bearing designs. This reduction is primarily due to their unique structural design, which facilitates better lubrication flow and minimizes wear over time.

Moreover, tapped bearings excel in applications with dynamic loads, as their construction allows for a more stable performance under varying conditions. A study conducted by the Society of Tribologists and Lubrication Engineers (STLE) indicates that components using tapped bearings exhibit a 25% increase in life span when subjected to high load situations, translating to fewer maintenance requirements and lower operational costs.

Tip: When selecting tapped bearings for your application, consider the operational environment and load conditions to maximize their benefits, as the right choice can significantly boost efficiency and lifetime. Additionally, regular maintenance checks can help maintain optimal performance, ensuring that lubrication systems are functioning effectively to support these advanced bearings.

Future Innovations in Tapped Bearing Technology and Design

Future innovations in tapped bearing technology and design are poised to revolutionize various industrial applications. One significant advancement is the integration of smart materials and sensors embedded within the bearing systems. These smart bearings can provide real-time data regarding load, temperature, and wear, enabling predictive maintenance that minimizes downtime and enhances efficiency. Additionally, the use of advanced composites and lightweight materials is expected to improve both the performance and durability of tapped bearings, making them more efficient for high-speed and high-pressure applications.

Moreover, the design of tapped bearings is evolving with the help of computer-aided design (CAD) and simulation technologies. Engineers can now create optimized bearing geometries that reduce friction and increase load capacity. This innovation not only enhances the mechanical performance but also contributes to energy savings in machinery. The continuous exploration of 3D printing technology is further promising, as it allows for the rapid prototyping of complex bearing designs tailored to specific operational needs, streamlining production processes and reducing costs.

Enhanced Mechanical Performance with Tapped Bearings

This chart illustrates the performance metrics of tapped bearings, highlighting their load capacity, friction coefficient, durability, and cost. Such metrics are essential for understanding how modifications in tapped bearing technology can enhance mechanical performance in future innovations.

Related Posts

-

10 Essential Tips for Choosing the Perfect Tapped Bearing

-

10 Facts About Real Bearing for Optimal Performance in Your Machinery

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

How to Choose the Right Tapped Bearing for Your Application Needs

-

Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

-

How to Optimize Your Projects with Tape Bearing Solutions