Revolutionizing Motion: How Stick Bearings Enhance Efficiency in Modern Machinery

In today's fast-paced industrial landscape, the demand for enhanced efficiency and reliability in machinery has never been greater. As highlighted in the recent report by the International Federation of Robotics (IFR), the global robotics market is projected to reach $210 billion by 2025, driving innovations in materials and components essential for effective operations.

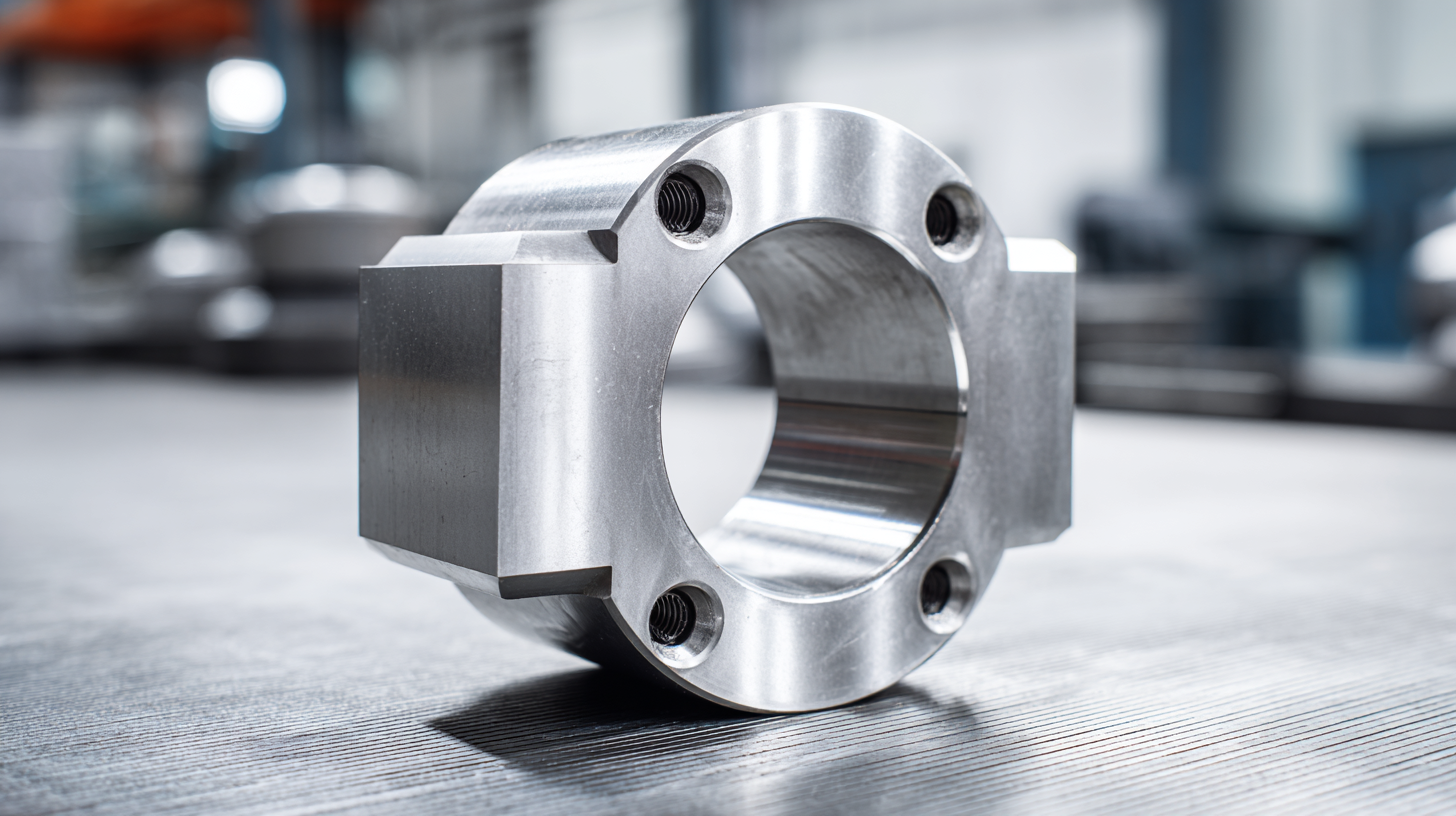

The Basics of Stick Bearings: Understanding Their Structure and Function

Stick bearings are critical components in modern machinery, providing a streamlined solution for reducing friction and enhancing overall efficiency. These bearings consist of a simple structure that maintains a durability and reliability essential in high-performance applications. According to industry reports, stick bearings can decrease energy consumption by up to 20% compared to traditional rolling element bearings. This efficiency is crucial as manufacturers increasingly seek to optimize their operations and reduce operational costs.

Understanding the function of stick bearings is fundamental for engineers and technicians. Their design allows for smooth movement between stationary and moving parts, which is essential in applications such as conveyor systems and electric motors. Furthermore, a recent study indicated that the adoption of stick bearings can lead to a significant reduction in maintenance requirements, as their simplified design leads to less wear over time. By adhering to the fundamentals of stick bearing technology, industries can enhance their operational efficiencies and stay competitive in a rapidly evolving market.

Stick Bearings Efficiency Analysis

This chart illustrates the various performance attributes of stick bearings, emphasizing their low friction coefficient, significant load capacity, excellent durability, notable efficiency increase, and maintenance frequency. These characteristics make them a cornerstone in modern machinery efficiency improvements.

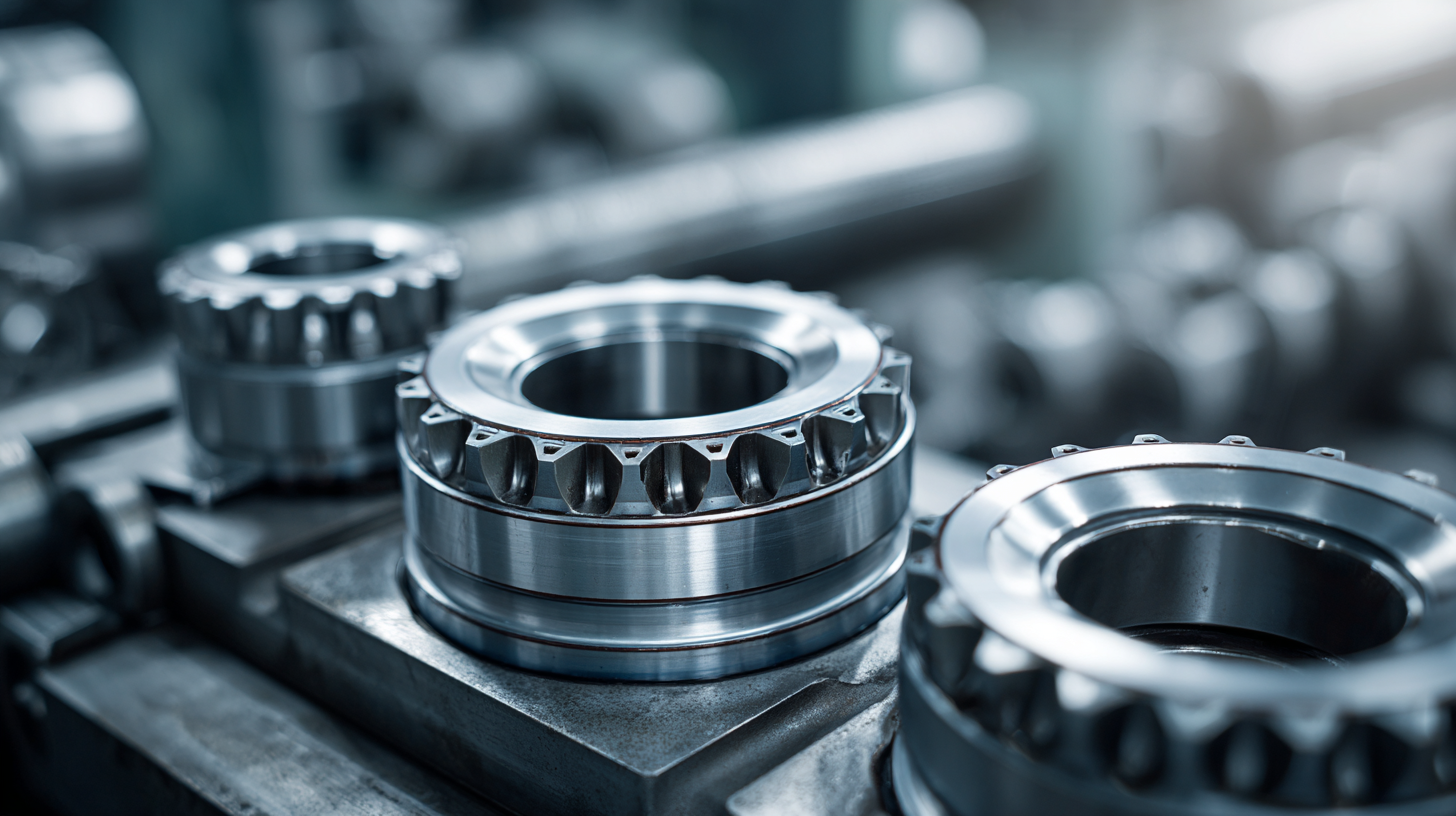

Key Advantages of Stick Bearings in Modern Machinery Efficiency

Stick bearings are making significant strides in modern machinery, offering a range of key advantages that enhance efficiency across various applications. One of the primary benefits lies in their ability to reduce friction, which is essential for the smooth operation of machinery. When integrated into devices, stick bearings minimize energy loss, thereby improving overall performance and extending the lifespan of equipment. This reduction in friction is akin to the advancements seen in graphene-wrapped diamond ball bearings, which also aim to slash energy consumption.

Stick bearings are making significant strides in modern machinery, offering a range of key advantages that enhance efficiency across various applications. One of the primary benefits lies in their ability to reduce friction, which is essential for the smooth operation of machinery. When integrated into devices, stick bearings minimize energy loss, thereby improving overall performance and extending the lifespan of equipment. This reduction in friction is akin to the advancements seen in graphene-wrapped diamond ball bearings, which also aim to slash energy consumption.

In addition to friction reduction, modern stick bearings are engineered to withstand challenging environmental conditions. Innovations have led to the development of bearings with enhanced resistance to UV light and moisture, making them suitable for demanding applications such as solar trackers. These advancements ensure that machines operate reliably, even when exposed to harsh elements. Furthermore, ongoing research into materials that can counteract issues like stick-slip phenomena demonstrates a commitment to perfecting the motion dynamics in machinery. By leveraging these technological improvements, manufacturers can achieve unprecedented levels of efficiency and reliability in their products.

Innovative Applications: How Stick Bearings Transform Various Industries

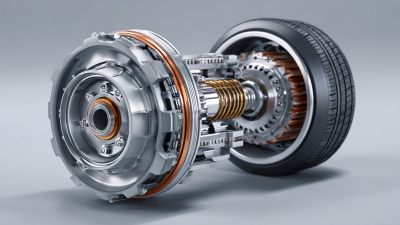

Stick bearings, a cutting-edge innovation in the engineering sector, are redefining efficiency in numerous industries by minimizing friction and enhancing load-bearing capabilities. According to a recent report from the International Journal of Mechanical Engineering, stick bearings can reduce energy consumption by up to 20% compared to traditional bearing systems. This substantial efficiency gain is particularly valuable in applications where machinery operates continuously under heavy loads, such as in automotive manufacturing and heavy machinery assembly lines.

In the aerospace industry, the adoption of stick bearings is transforming aircraft design and maintenance. The Aircraft Engineering and Maintenance report indicates that the lightweight nature of stick bearings contributes to a reduction in aircraft weight by approximately 15%. This reduction not only improves fuel efficiency but also enhances overall performance and longevity of the aircraft. Moreover, the resilience of stick bearings against extreme environmental conditions makes them ideal for use in satellites and spacecraft, where reliability is paramount. The integration of stick bearings into various industrial applications showcases their potential to drive innovation and foster improvements across multiple sectors, leading to more sustainable operational practices.

Maintenance Tips for Maximizing the Life of Stick Bearings

Stick bearings are a critical component in modern machinery, and proper maintenance is essential to maximize their lifespan and efficiency. Regular inspection is paramount; industry reports indicate that up to 70% of bearing failures can be tracked back to inadequate maintenance practices. By implementing a rigorous schedule for checking lubrication levels and ensuring proper alignment, operators can significantly reduce the likelihood of premature wear.

In addition to regular inspections, selecting the right type of lubricant is crucial. According to a study by the American Society of Mechanical Engineers, using high-quality synthetic lubricants can extend bearing life by 25% compared to conventional options. Furthermore, maintaining optimal operating temperatures is vital, as excessive heat can degrade lubricant effectiveness and lead to component failure. As equipment increasingly demands efficiency and reliability, adhering to these maintenance tips will ensure that stick bearings operate at their best, contributing to enhanced machinery performance.

Future Trends: The Role of Stick Bearings in Advancing Machine Technology

The emergence of stick bearings is reshaping the landscape of machine technology, fostering enhanced efficiency and reliability. These innovative components optimize load distribution and reduce friction, enabling machinery to operate at peak performance levels. As industries increasingly adopt automation and precision engineering, stick bearings are becoming pivotal in facilitating smoother, quieter, and more efficient machine functions. Their lightweight construction contributes to overall energy savings, aligning with the growing emphasis on sustainability in industrial processes.

Looking forward, the role of stick bearings in advancing machine technology is expected to expand significantly. Innovations in materials science and manufacturing techniques are likely to enhance their performance and durability, making them suitable for even more demanding applications. Moreover, with the rise of Industry 4.0, stick bearings will play a critical role in smart manufacturing solutions, where real-time data and predictive maintenance are integral.

As we move into a more interconnected era, stick bearings are not just components; they are key enablers of technological advancement, paving the way for the next generation of machinery.

Related Posts

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

The Critical Role of Hub Bearings in Enhancing Vehicle Safety and Performance Vital Statistics You Should Know

-

10 Facts About Real Bearing for Optimal Performance in Your Machinery

-

7 Essential Tips for Choosing the Best Pillar Bearing for Your Needs

-

10 Essential Tips for Choosing the Perfect Tapped Bearing

-

Unlocking Performance: The Essential Role of Tire Bearings in Modern Vehicle Dynamics