Why Are Rotor Bearings Essential for Machinery Performance?

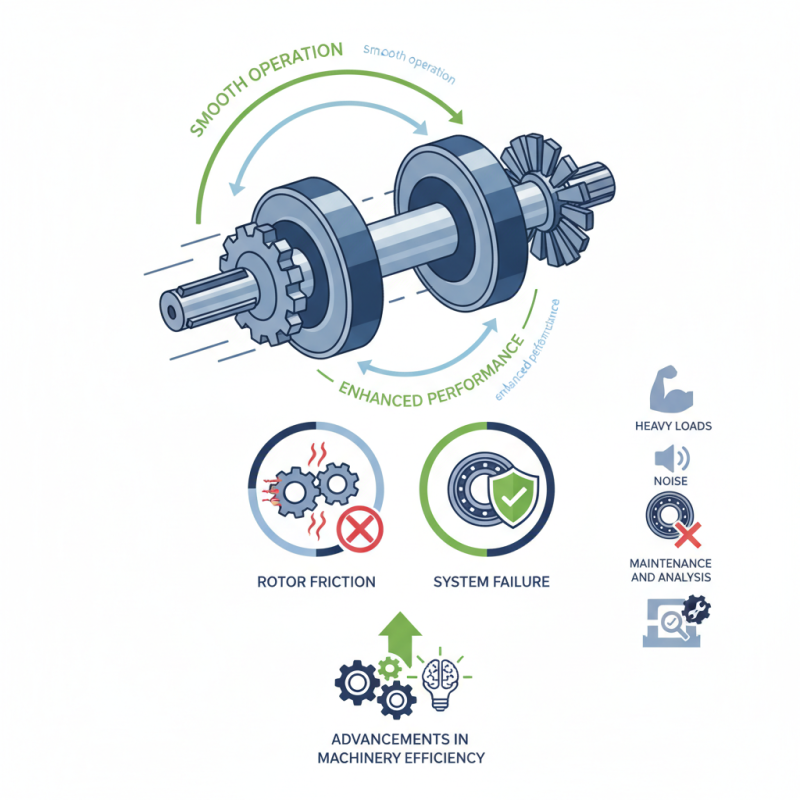

In the world of machinery, rotor bearings play a crucial role. They ensure smooth operation and enhance performance. According to Dr. John Matthews, a leading expert in rotor dynamics, "Rotor bearings are the backbone of any rotating system." This statement emphasizes their importance.

The efficiency of machinery often relies on these components. Properly functioning rotor bearings reduce friction and heat. They also prevent wear and tear. When rotor bearings fail, the entire system can suffer. Machinery may become less efficient or even fail completely.

However, not all rotor bearings perform equally. Some may struggle under heavy loads. Others might generate excessive noise. Recognizing these issues is vital for improvement. Regular maintenance and analysis are necessary to uphold performance and longevity. Understanding rotor bearings can lead to significant advancements in machinery efficiency.

Importance of Rotor Bearings in Machinery Performance Optimization

Rotor bearings play a crucial role in machinery performance optimization. They help reduce friction, ensuring smoother operation of various mechanical components. According to a recent industry report, over 40% of machinery failures are linked to bearing issues. This statistic highlights how essential rotor bearings are in maintaining the integrity of equipment.

The efficiency of rotors often hinges on the quality of their bearings. Poor bearing condition can lead to vibrations and misalignments, which ultimately affect overall performance. Research indicates that optimizing bearing maintenance can improve operational efficiency by up to 30%. Many operators overlook this fact, focusing instead on other components. This oversight can lead to increased downtime and higher repair costs in the long run.

It's also important to recognize that not all rotor bearings are created equal. Variability in performance can be observed across different manufacturing processes. Some users may choose bearings without considering the specific requirements of their machines. This choice can lead to subpar performance and unexpected failures. Experimenting with different bearing types and understanding their specifications is essential for maximizing machinery performance.

Types of Rotor Bearings and Their Roles in Different Applications

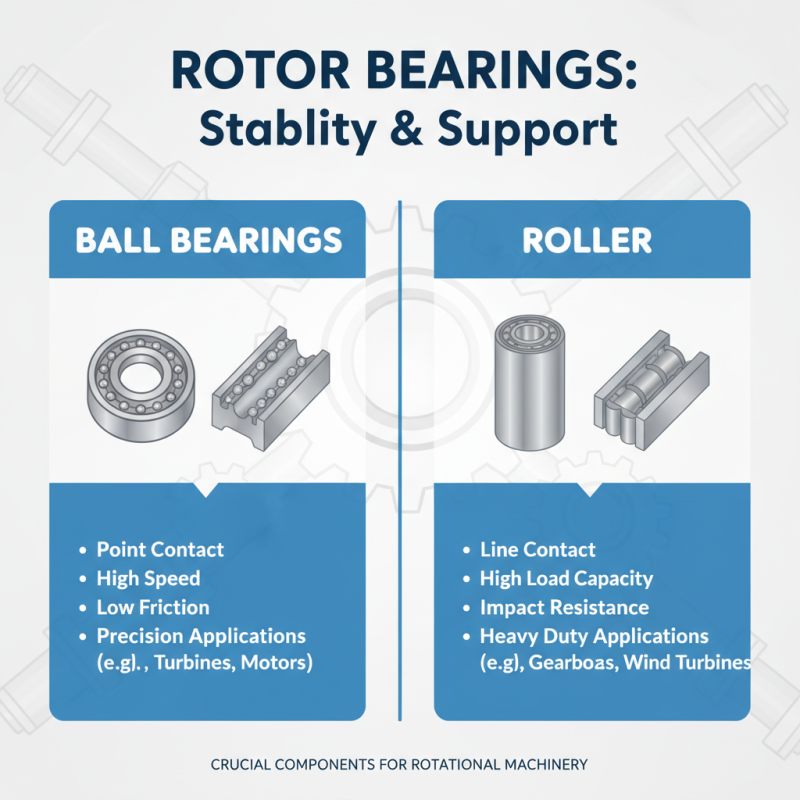

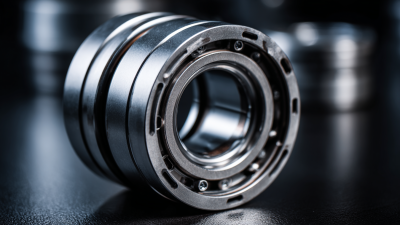

Rotor bearings are crucial components in machinery. They support rotor shafts and help maintain stability during operation. The two common types of rotor bearings are ball bearings and roller bearings. Each type serves a unique function in various applications.

Ball bearings are widely used in high-speed applications. They reduce friction and handle loads efficiently. For example, in electric motors, ball bearings enhance performance by minimizing energy loss. Roller bearings, on the other hand, can accommodate heavier loads. They excel in industrial machines where robustness is key. According to industry reports, roller bearings can handle up to 20% more load compared to ball bearings of the same size.

Tip: Regular maintenance of rotor bearings increases machinery lifespan. Monitor alignment and lubrication levels to prevent premature wear. Despite advances in technology, users still face challenges, such as bearing noise and obsolescence. Addressing these issues requires constant vigilance and adaptation in maintenance strategies. The choice of rotor bearings relies on specific application needs; one size does not fit all.

Impact of Bearing Materials on Rotor Efficiency and Durability

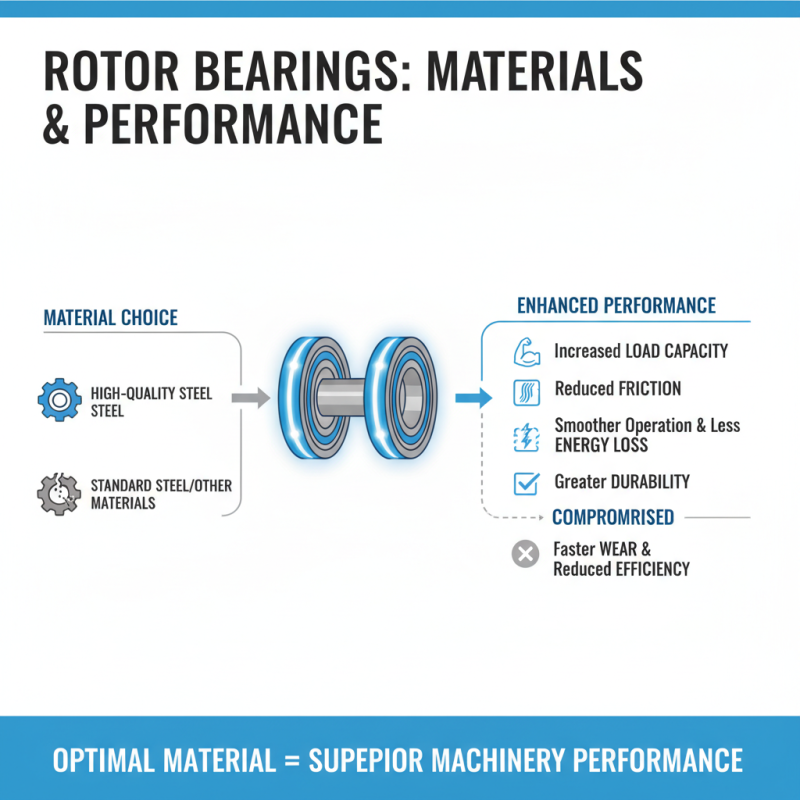

Rotor bearings play a pivotal role in machinery performance. The choice of materials significantly influences rotor efficiency and durability. For instance, high-quality steel can enhance load capacity and reduce friction. This results in smoother operation and less energy loss. However, not all steel grades perform equally. Some might wear out quicker in specific applications.

Other materials, such as ceramics, offer unique advantages. They are lightweight and resist corrosion better than metals. This can lead to extended service life. However, ceramics can be brittle and prone to cracking under extreme conditions. Assessing the operating environment is crucial when selecting bearing materials. Sometimes, a mix of materials can yield the best outcomes.

The impact of bearing design also cannot be overlooked. Inadequate design can lead to failures, even with the best materials. Rotors may experience increased vibration and noise if bearings are poorly aligned. Regular maintenance is essential but can be overlooked. Ignoring these factors may lead to efficiency losses that compound over time. Understanding these nuances is vital for optimal rotor performance.

Common Failure Modes of Rotor Bearings and Their Solutions

Rotor bearings play a crucial role in machinery performance. They support rotating elements and reduce friction. However, these components face various failure modes. Understanding these modes can enhance reliability and efficiency in machinery.

One common failure mode is wear. Over time, bearings may lose their smooth surface, causing inefficiencies. Regular inspection can help detect early signs of wear. Another issue is contamination. Dirt and debris can infiltrate, leading to premature failure. Using proper seals and filters can mitigate this risk.

Another concern is misalignment. Misalignment can cause uneven wear and overheating. Routine maintenance checks can address misalignments before they escalate. Sometimes, operators overlook these issues. A proactive approach is essential for sustaining machinery performance over time. Regular training for staff can help raise awareness of these potential failures.

Maintenance Strategies to Enhance Rotor Bearing Longevity and Performance

Rotor bearings play a crucial role in machinery performance. They support rotating shafts and minimize friction, helping to maintain efficiency and longevity. Regular maintenance is vital for ensuring these components operate effectively. A study by the International Society of Automation found that improper lubrication accounts for 25% of all bearing failures.

Effective maintenance strategies include regular inspections and proper lubrication management. Monitoring the temperature and vibration levels of rotor bearings can also prevent unexpected breakdowns. In fact, predictive maintenance can reduce downtime by 30%, according to the American Society of Mechanical Engineers. Remember to track operational hours. This data indicates when bearings may need replacement or servicing.

However, maintaining rotor bearings is not always straightforward. Operators may overlook minor issues until they escalate, leading to costly repairs and reduced machinery performance. Sometimes, employees need training to properly identify early warning signs. Inadequate knowledge can diminish the effectiveness of maintenance efforts. Therefore, investing in staff education is essential to enhance overall machinery reliability.

Related Posts

-

Best Real Bearing Types for Your Needs?

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

Understanding Deep Bearing: Types, Applications, and Benefits Explained

-

How to Choose the Right Real Bearing for Your Needs?

-

10 Facts About Real Bearing for Optimal Performance in Your Machinery

-

What is Tapped Bearing and How Does It Enhance Mechanical Performance