How to Optimize Your Projects with Tape Bearing Solutions

As industries increasingly focus on enhancing efficiency and reducing operational costs, the integration of innovative solutions like Tape Bearing has emerged as a crucial strategy. According to a recent report by the National Institute of Standards and Technology, approximately 20% of machinery downtime can be attributed to bearing failures, underscoring the need for advanced solutions that improve reliability and performance. Tape Bearings, known for their unique ability to handle high loads while reducing friction, have garnered attention in sectors ranging from automotive to aerospace. A study by Global Industry Analysts suggests that the market for bearing technologies, including Tape Bearings, is projected to reach $96 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.3%. By optimizing projects with Tape Bearing solutions, companies can significantly enhance their operational efficiency, leading to increased productivity and reduced maintenance costs.

Understanding the Basics of Tape Bearing Solutions for Project Optimization

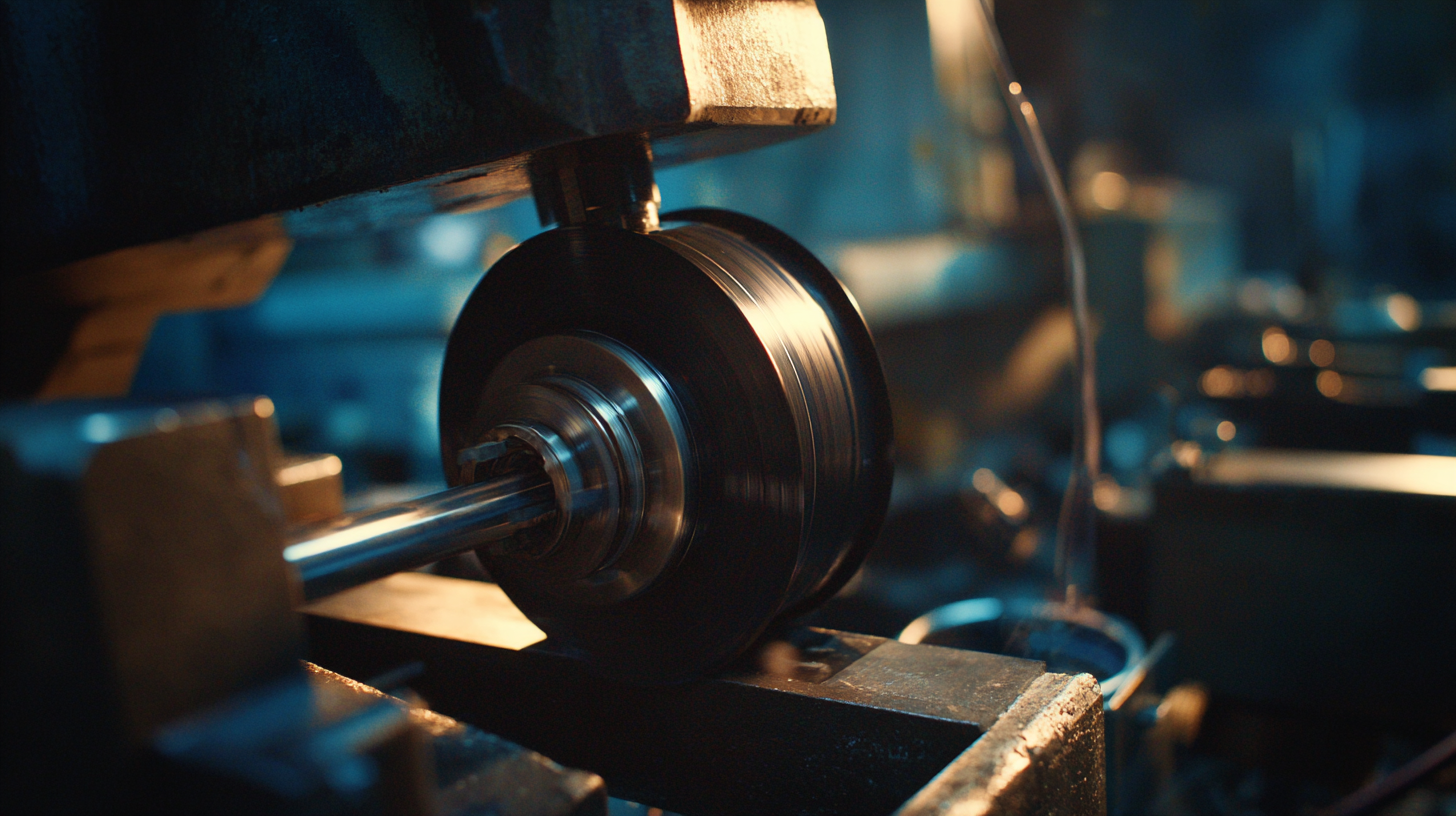

Tape bearing solutions have emerged as a powerful tool in optimizing project performance across various industries. These innovative systems utilize a low-friction interface created by tapes that can significantly reduce wear and energy consumption. According to a report from the American Society of Mechanical Engineers (ASME), implementing tape bearing solutions can lead to a reduction in maintenance costs by up to 30%, ultimately enhancing operational efficiency.

Understanding the fundamentals of how tape bearings function is crucial for project managers. Tape bearings operate by distributing loads evenly over the surface, which minimizes point stresses and prolongs the lifespan of equipment. The International Journal of Mechanical Engineering published findings indicating that projects powered by tape bearing solutions witnessed an increase in reliability by 25%, allowing teams to focus on innovation rather than maintenance. This optimization not only contributes to project success but also fosters a sustainable approach, reducing the environmental impact associated with frequent replacements and repairs.

Optimizing Project Efficiency with Tape Bearing Solutions

Key Benefits of Integrating Tape Bearings in Your Projects

Integrating tape bearings into your projects can yield significant advantages in various applications. One of the primary benefits is reduced friction, which enhances efficiency and extends the lifespan of mechanical components. Tape bearings are designed to provide a smooth and durable interface, minimizing wear and tear. This is particularly advantageous for projects that require precise motion, such as robotics and aerospace engineering, where even the slightest improvement in friction can lead to substantial performance gains.

Integrating tape bearings into your projects can yield significant advantages in various applications. One of the primary benefits is reduced friction, which enhances efficiency and extends the lifespan of mechanical components. Tape bearings are designed to provide a smooth and durable interface, minimizing wear and tear. This is particularly advantageous for projects that require precise motion, such as robotics and aerospace engineering, where even the slightest improvement in friction can lead to substantial performance gains.

Another key benefit of using tape bearings is their adaptability in harsh environments. These bearings are often resistant to extreme temperatures, moisture, and dust, making them ideal for outdoor or industrial applications. Their ability to function reliably under such conditions allows engineers to develop more robust and dependable designs, ensuring that projects can withstand the rigors of everyday use. Additionally, tape bearings can be customized to fit specific requirements, offering flexibility that traditional bearings may not provide. By incorporating tape bearings, project managers can achieve higher reliability and reduced maintenance costs.

Best Practices for Selecting the Right Tape Bearing Type

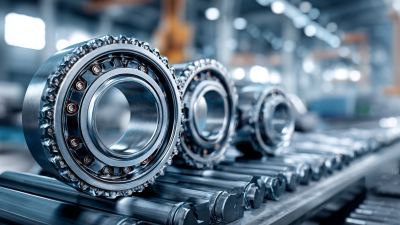

When selecting the right tape bearing type for your projects, it's crucial to consider various factors that can optimize performance and longevity. Tape bearings are often favored for their lightweight characteristics and efficiency in reducing friction. However, the choice between different types of tape bearings, such as metal-polymer versus traditional options, can significantly impact the outcome of your project.

When it comes to selecting, one of the best practices is to assess the specific application requirements. Consider the load conditions, environmental factors, and the speed at which the bearings will operate. For instance, metal-polymer bearings have been recognized for their resilience and suitability in high-load scenarios, making them an attractive substitute for conventional bearings.

Tips: Always prioritize compatibility with your machinery when choosing a bearing type. Test prototypes in the environments they’ll be operating in to ensure optimal performance. Additionally, consult with manufacturers or industry experts to get insights on the latest advancements and materials that can enhance your project’s efficiency.

How to Optimize Your Projects with Tape Bearing Solutions - Best Practices for Selecting the Right Tape Bearing Type

| Tape Bearing Type | Load Capacity (N) | Friction Coefficient | Temperature Range (°C) | Typical Applications |

|---|---|---|---|---|

| PTFE Tape Bearings | 2000 | 0.05 - 0.15 | -200 to 260 | Chemical processing, food industry |

| Steel Tape Bearings | 5000 | 0.1 - 0.2 | -40 to 250 | Heavy machinery, construction |

| Bronze Tape Bearings | 3000 | 0.15 - 0.25 | -30 to 200 | Automotive, marine |

| Nylon Tape Bearings | 1000 | 0.25 - 0.35 | -40 to 85 | Consumer products, electronics |

Common Challenges and Solutions in Tape Bearing Implementations

Implementing tape bearing solutions can significantly enhance project efficiency, but various challenges often arise in the process. Common issues include adhesive failure, improper alignment, and environmental compatibility. According to a report by the American Society of Mechanical Engineers, nearly 30% of tape bearing implementations face performance degradation due to inadequate surface preparation. Ensuring that surfaces are clean and properly treated can mitigate this risk.

Tips: Always conduct a thorough surface analysis before applying tape bearings. Utilize surface primers where necessary to improve adhesion, and consider conducting trials to measure bonding strength under different conditions.

Another challenge is the need for precise alignment during installation. Misalignment can lead to uneven load distribution, which may result in premature failure. A study by the International Journal of Advanced Manufacturing Technology revealed that misalignment can reduce the lifespan of bearings by up to 40%. Employing alignment tools and techniques can substantially alleviate this issue, ensuring that the tape bearings function optimally over time.

Tips: Invest in laser alignment tools to achieve precise placement and periodically reassess alignment during the project's lifecycle to maintain performance integrity.

Analyzing Performance Metrics to Enhance Project Outcomes with Tape Bearings

Incorporating tape bearing solutions into project designs can significantly impact performance metrics, leading to enhanced outcomes. Recent studies indicate that projects utilizing advanced tape bearings can experience a reduction in friction losses by up to 30%. This not only improves overall efficiency but also extends the lifespan of machinery by minimizing wear and tear. According to the International Journal of Mechanical Engineering, equipment downtime can decrease by as much as 25% when optimized tape bearings are employed, resulting in substantial savings in maintenance costs and operational interruptions.

Additionally, analyzing performance metrics such as load capacity and thermal management can further refine the benefits provided by tape bearings. A recent report from the Society of Manufacturing Engineers found that projects that incorporated these metrics in their evaluations were able to achieve a 15% increase in load capacity under dynamic conditions. By focusing on these parameters, engineers can tailor tape bearing solutions to meet specific project needs, resulting in smoother operations and better resource allocation. Utilizing data-driven approaches to optimize tape bearing applications leads to measurable improvements in efficiency and project success, ultimately achieving superior outcomes in competitive environments.

Related Posts

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

7 Essential Tips for Choosing the Right Rear Bearing for Your Production Needs

-

Exploring Opportunities for Auto Bearings at the 138th Canton Fair 2025: Industry Trends and Insights

-

10 Facts About Real Bearing for Optimal Performance in Your Machinery

-

How to Choose the Right Deep Bearing for Your Industrial Needs

-

Understanding the Functionality and Benefits of Nup Bearing Types