Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

Needle bearings represent a critical innovation in the field of mechanical engineering due to their unique design and superior load-bearing capacity. Characterized by their elongated roller elements, needle bearings are ideal for applications where space is limited, yet high precision and efficiency are required. According to a report by MarketsandMarkets, the global needle bearing market is projected to reach USD 14.5 billion by 2026, growing at a CAGR of 5.1%. This growth underscores the increasing demand for lightweight and compact components across various industries, including automotive, aerospace, and industrial machinery. As engineers seek innovative solutions to enhance performance and reduce manufacturing costs, understanding the advantages of needle bearings becomes paramount. Their ability to handle high radial loads while minimizing friction makes them an indispensable component in the design of modern machinery and equipment, offering a blend of durability and efficiency that is crucial for innovative engineering solutions.

Exploring the Functionality of Needle Bearings in Modern Engineering Applications

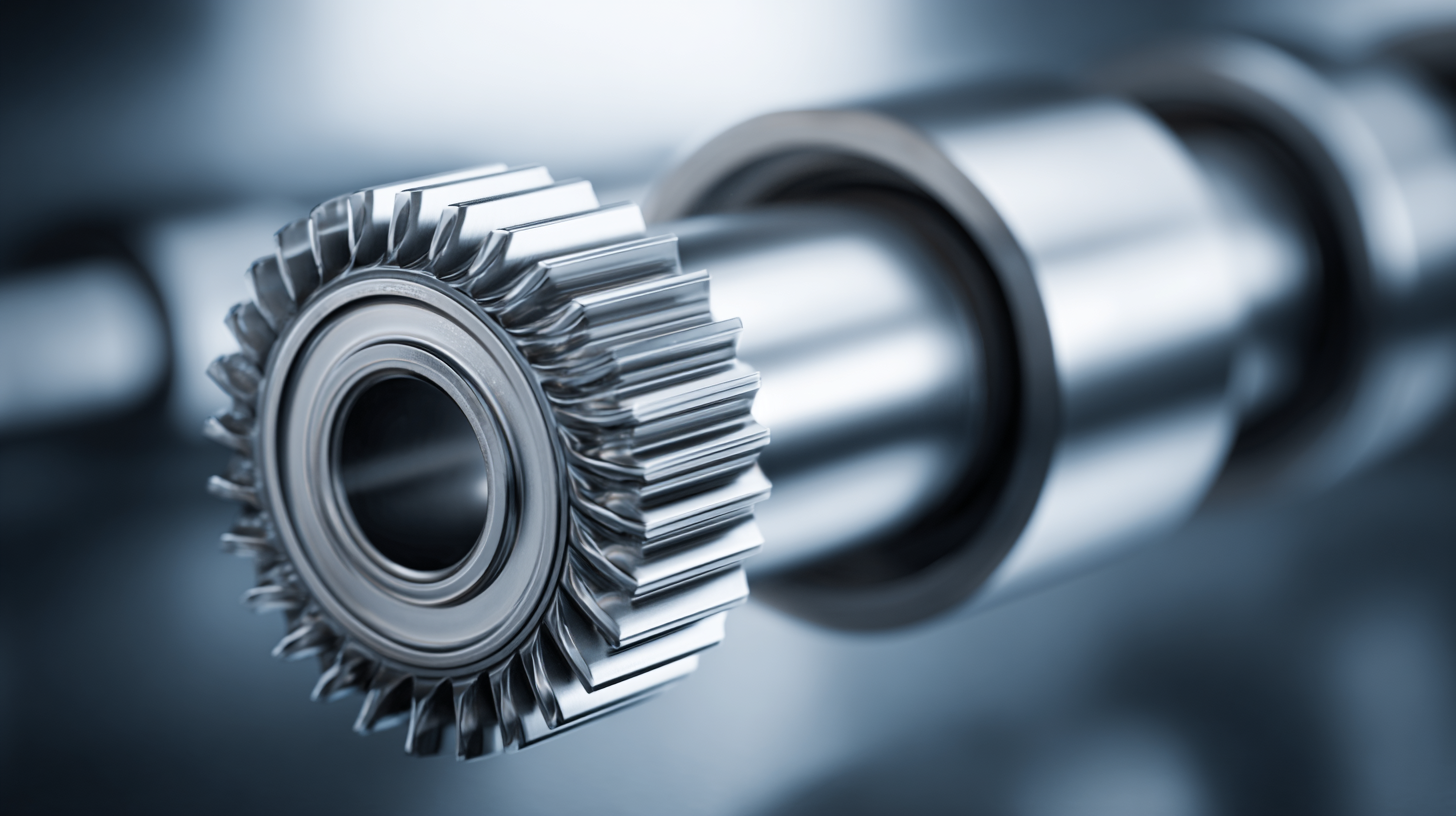

Needle bearings play a vital role in modern engineering applications due to their unique design and functionality. These components are characterized by their elongated rollers, which enable them to provide a high load-carrying capacity while maintaining a compact size. This makes them an excellent choice for applications where space is limited but high performance is essential. By reducing friction and enhancing efficiency, needle bearings allow engineering solutions to operate more smoothly, resulting in improved durability and extended service life for various machinery.

In automotive, aerospace, and industrial machinery, the functionality of needle bearings is particularly pronounced. They are commonly used in crankshafts, transmission systems, and various rotational components. The reduced surface area in contact minimizes wear and heat generation, making systems more reliable under high stress. Moreover, needle bearings support both radial and axial loads, which enhances their versatility in different engineering designs. As a result, engineers are increasingly integrating needle bearings into their innovative solutions, recognizing their potential to optimize performance while addressing the challenges of modern mechanical systems.

Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

| Aspect | Details |

|---|---|

| Load Capacity | High load capacity due to larger surface area contact. |

| Space Efficiency | Compact design allows for space-saving applications. |

| Friction Reduction | Minimized friction leads to improved efficiency and heat reduction. |

| Durability | Long service life with resistance to wear and tear. |

| Alignment | Self-alignment properties help reduce stress on adjacent components. |

| Applications | Widely used in automotive, aerospace, and robotics for their efficiency. |

| Lubrication Needs | Can operate effectively with minimal lubrication, enhancing reliability. |

Identifying Key Benefits of Needle Bearings in Reducing Friction and Wear

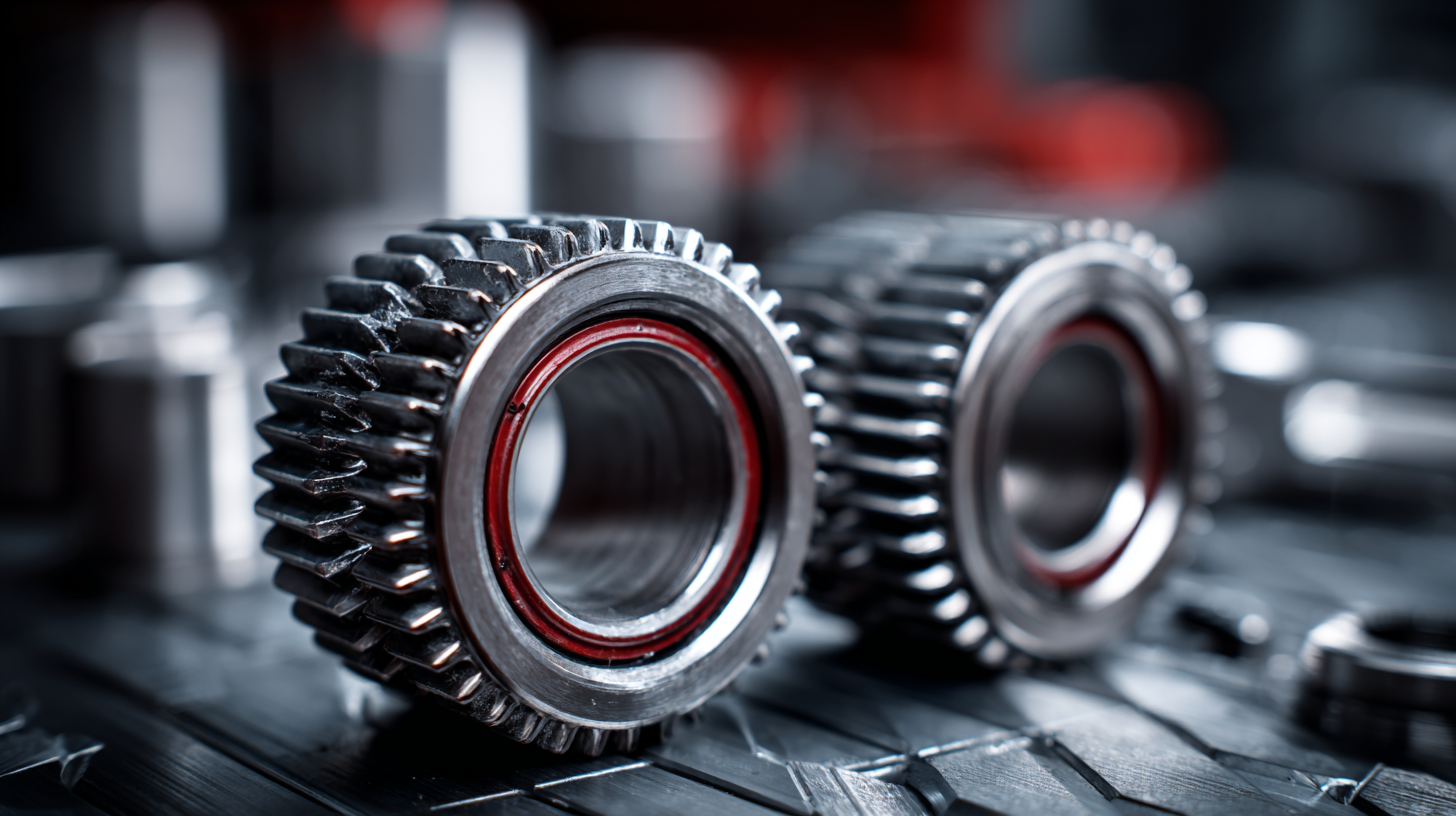

Needle bearings, characterized by their thin cylindrical rollers, present several advantages that significantly reduce friction and wear in various engineering applications. Their design allows for a higher load-bearing capacity within a compact space, making them ideal for applications where conserving space is essential. The minimal contact area between the needles and the raceway results in reduced frictional forces, which enhances the overall efficiency of mechanical systems.

Moreover, the precision alignment provided by needle bearings minimizes surface wear, promoting longevity in components. By distributing loads evenly across the bearing surface, they help to maintain the integrity of both the bearing and the parts it supports. This characteristic is particularly beneficial in high-speed applications where excessive wear can lead to failures. Consequently, engineers increasingly turn to needle bearings as a reliable solution, ensuring both performance improvements and cost-effectiveness in their designs.

Comparative Analysis: Needle Bearings vs Traditional Bearing Types

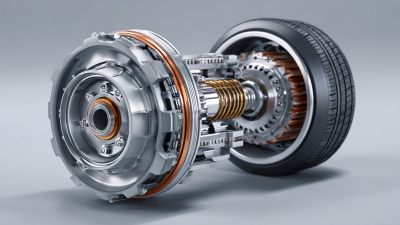

Needle bearings have emerged as a game-changer in the engineering landscape, particularly in sectors like electric vehicles (EVs) where efficiency and space-saving solutions are crucial. Unlike traditional bearing types, needle bearings feature long, slender rollers that minimize friction and can handle higher loads in limited spaces. This makes them particularly well-suited for applications in EVs, where lightweight and compact components are essential for enhancing performance and range.

When comparing needle bearings to traditional spherical or cylindrical bearings, the advantages become clear. Needle bearings exhibit lower weight and smaller dimensions without sacrificing strength and durability. This is vital in innovative engineering applications that demand both robustness and efficiency, such as in the automotive industry, where the demand for EV components is on the rise from 2024 to 2034.

Tips: When selecting bearings for your engineering projects, consider the specific load requirements and space constraints. Additionally, evaluate the lubrication methods, as proper lubrication is key to maximizing the lifespan of needle bearings. Keep abreast of market trends in the electric vehicle sector to ensure that you're using the most advanced bearing technologies available.

Implementing Needle Bearings: Best Practices for Innovative Design

Needle bearings have gained popularity in innovative engineering solutions due to their compact design and efficiency in load distribution. When implementing needle bearings, several best practices can help ensure optimal performance and longevity. First, it is crucial to select the appropriate type of needle bearing based on the specific application requirements. Factors such as load capacity, speed, and operating conditions should be carefully evaluated to choose the right bearing.

**Tips: Ensure proper alignment during installation to prevent premature wear. Additionally, regular maintenance checks can help identify issues early, allowing for timely interventions.**

Another important aspect is the lubrication of needle bearings. Using the right lubricant not only minimizes friction but also prevents overheating and reduces wear. It's beneficial to follow manufacturer recommendations to establish a suitable lubrication schedule.

**Tips: Consider using grease for applications with low speeds and moderate loads, while oil may be preferable for high-speed, high-load environments. Regularly inspect your lubrication system for effectiveness.**

By adhering to these best practices, engineers can fully exploit the advantages of needle bearings, leading to enhanced performance and innovation in their designs.

Understanding the Advantages of Needle Bearings

Future Trends: The Role of Needle Bearings in Advanced Engineering Solutions

As the global bearings market continues to evolve, needle bearings are emerging as a pivotal component in advanced engineering solutions. The market size for these bearings was valued at approximately USD 46.82 billion in 2024, projected to grow significantly, reaching USD 97.10 billion by 2030. This growth is largely driven by the increasing demand for automotive applications, where the needle roller bearing market alone exceeded USD 2.9 billion in 2023 and is expected to expand at a CAGR of around 6.5% through 2032.

Needle bearings offer unique advantages, such as high load capacity and reduced friction, making them ideal for applications requiring compact design and efficient performance. As industries innovate, the trend is shifting towards employing these bearings in more sophisticated machinery, where they are essential for improving reliability and overall performance.

Tips: When considering needle bearings for your projects, focus on their material types and lubrication methods, as these factors can drastically influence performance. Additionally, keep an eye on market forecasts to make informed decisions about your engineering solutions.

Related Posts

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

7 Essential Tips for Choosing the Right Rear Bearing for Your Production Needs

-

Forecasting the Brake Bearings Market Growth Amidst the 138th China Import and Export Fair in 2025

-

How to Choose the Right Pillar Bearing for Your Industrial Needs

-

How to Choose the Right Pillow Bearing for Your Industrial Applications

-

Unlocking Performance: The Essential Role of Tire Bearings in Modern Vehicle Dynamics