How to Install a Tapped Bearing for Optimal Performance?

Tapped bearings are crucial in ensuring smooth operations across various machinery. Utilizing tapped bearings effectively can enhance performance and reduce downtime. According to a 2022 industry report by Incipient Edge, proper installation can improve bearing life by up to 30%. This statistic emphasizes the significance of installation techniques.

The precision required during the installation of tapped bearings cannot be overstated. Proper alignment and torque settings are essential. Research indicates that misalignment can lead to excessive wear and tear, impacting overall efficiency. In fact, 40% of mechanical failures trace back to improper bearing installation. This highlights a common pitfall that needs reflection and improvement within the industry.

Beyond technical skills, understanding how various applications affect tapped bearing performance is vital. Different environments can impose unique stressors. For instance, vibrational forces in heavy machinery may challenge bearing integrity. Awareness of these factors allows for anticipatory measures, ultimately leading to better decisions during installation.

Understanding Tapped Bearings and Their Applications

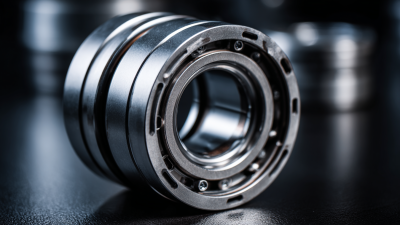

Tapped bearings are critical components in various mechanical systems. These bearings feature a threaded hole that allows for easier installation and adjustment. They are extensively used in applications such as robotics, automotive systems, and heavy machinery. According to industry reports, around 40% of mechanical failure relates to improper bearing selection or installation. This statistic underlines the importance of understanding tapped bearings for optimal performance.

Their versatility makes tapped bearings suitable for numerous applications. They can manage both radial and axial loads, a feature that contributes to their effectiveness. Industries often select tapped bearings for their ability to reduce friction between moving parts. This results in extended life cycles for machinery components. Regular maintenance can enhance performance, yet many operations neglect this aspect, leading to premature failures.

However, installing tapped bearings is not always straightforward. Misalignment during installation can lead to uneven wear and damage. A study highlights that 30% of installations cause issues due to lack of proper alignment tools. Furthermore, while tapped bearings can improve efficiency, they may require careful consideration of material compatibility for different environments. These nuances remind us of the need for thorough planning and execution when incorporating tapped bearings into designs.

Performance Comparison of Tapped Bearings Across Various Applications

Essential Tools and Materials for Installation

When installing a tapped bearing, choosing the right tools and materials is crucial. You will need a high-quality tapped bearing, a bearing puller, and various wrenches. A torque wrench is also vital for proper tightening. This ensures the bearing sits securely. Don’t forget to have lubricant on hand. It can significantly improve performance.

Check your workspace before starting. A clean environment reduces the chances of mistakes. Misalignment can ruin your installation. Pay attention to the bolt specifications. Using the wrong size can lead to failure.

Tips: Measure your bearing accurately. This avoids compatibility issues later. Also, be mindful of excess lubricant. Too much can attract dirt. Make sure to inspect everything before reassembly. Sometimes, steps may seem tedious, but they matter.

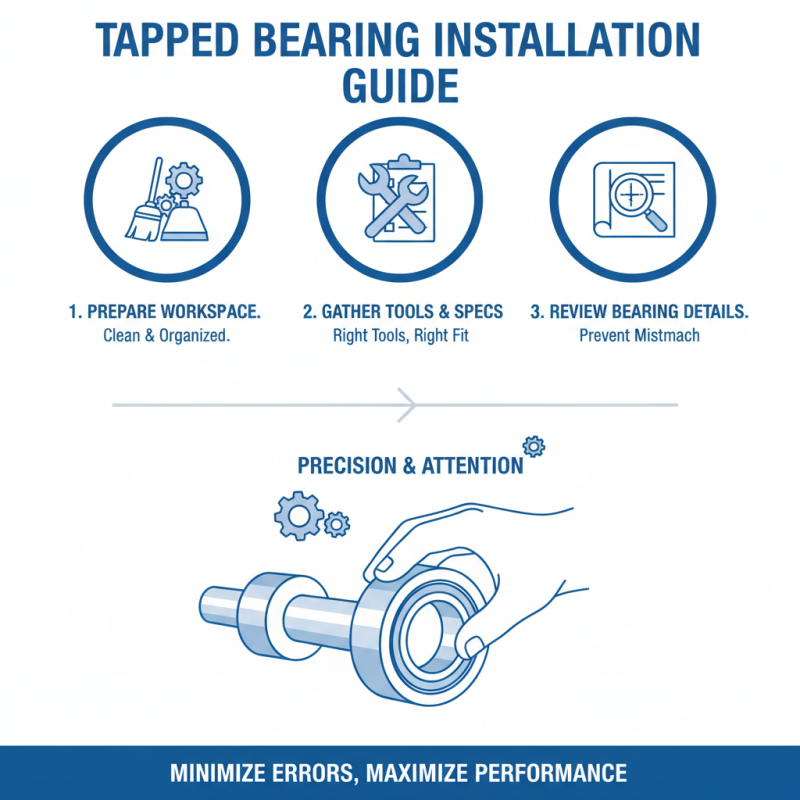

Step-by-Step Guide to Installing a Tapped Bearing

Installing a tapped bearing requires precision and attention to detail. Begin by preparing the workspace. Ensure you have all necessary tools. A clean area minimizes errors during installation. Before starting, review the specifications for the bearing you’re working with. This helps avoid mismatches that could lead to performance issues.

Next, carefully position the bearing at the intended site. Use a level to align it correctly. This step is often overlooked but crucial for optimal performance. Secure the bearing loosely with bolts. Don't tighten them completely at first. Make adjustments as needed. Tightening too quickly can cause alignment problems, leading to uneven wear.

Check your work periodically. It’s easy to miss small misalignments. If you find any, don’t hesitate to fix them. This might require going back a few steps. A rushed installation can lead to future headaches, like increased noise or decreased efficiency. Remember, it’s better to take your time. Investing effort upfront pays off in the long run.

Common Mistakes to Avoid During Installation

Installing a tapped bearing can significantly enhance the performance of your machinery. However, some common mistakes can undermine this process. One common error is failing to clean the installation area thoroughly. Dust and debris can affect bearing performance. Always ensure surfaces are spotless before starting.

Another frequent issue is improper alignment of the bearing. Misaligned components can lead to premature wear. It may seem easy, but take extra time to check your setup. Use tools like lasers or alignment jigs to ensure precision.

Tip: Regularly inspect the bearing after installation. Look for unusual noises or vibrations as signs of issues.

Many rush the installation. This can lead to incorrect torque being applied. Over-tightening can damage components, while under-tightening may lead to slippage. Remember, patience is key.

Tip: Keep a checklist for installation steps. This can help you avoid skipping essential tasks. Taking a moment to reflect on each step can make a big difference.

How to Install a Tapped Bearing for Optimal Performance? - Common Mistakes to Avoid During Installation

| Common Mistakes | Description | Impact | Prevention Tips |

|---|---|---|---|

| Incorrect Alignment | Failing to align the bearing properly can lead to uneven wear. | Increased friction and premature failure. | Use alignment tools to ensure proper positioning. |

| Insufficient Lubrication | Not applying enough lubricant can lead to overheating. | Reduced lifespan of the bearing. | Follow manufacturer’s specifications for lubrication. |

| Using Wrong Tools | Using inappropriate tools can damage the bearing. | Risk of bearing damage during installation. | Always use recommended tools for installation. |

| Ignoring Cleanliness | Dust and debris can contaminate the bearing. | Potential for bearing failure due to contamination. | Ensure a clean working environment before installation. |

| Neglecting Inspection | Skipping the inspection process can overlook defects. | Increased likelihood of mechanical failure. | Regularly inspect bearings for any signs of damage. |

Maintenance Tips for Long-lasting Optimal Performance

Maintaining tapped bearings is crucial for optimal performance. Regular maintenance can prevent unwanted wear and tear. Studies show that proper lubrication can extend bearing life by 30%. Ensuring the right lubricant type and viscosity is vital. Over-lubrication can cause overheating. Under-lubrication leads to insufficient protection.

Routine inspections are necessary. Check for signs of rust or grease leakage. Addressing these issues promptly can save money in the long run. It is important to keep operating temperatures within safe limits. High temperatures can lead to premature failure. Monitor these metrics regularly for the best results.

Education plays a key role in maintenance practices. Proper training for operators reduces mistakes. A report by the Bearing Specialists Association notes that 70% of bearing failures are due to improper handling. Small errors can lead to big problems. Focusing on preventive measures ensures longevity. Always remember, complacency can lead to failure.

Related Posts

-

10 Essential Tips for Choosing the Perfect Tapped Bearing

-

What is Tapped Bearing and How Does It Enhance Mechanical Performance

-

How to Choose the Right Tapped Bearing for Your Application Needs

-

How to Choose the Right Real Bearing for Your Needs?

-

Top 10 Uses of Stick Bearings in Modern Engineering Applications?

-

The Ultimate Guide to Choosing the Best Bearing Needles in 2025