The Ultimate Guide to Choosing the Best Bearing Needles in 2025

In the intricate world of mechanical engineering, the selection of the right components can make all the difference in performance and durability. Bearing needles, a critical component in various machinery, play a pivotal role in ensuring smooth operations and reducing friction. According to Dr. Emily Carter, a leading expert in the field of bearings and mechanical components, "Choosing the right bearing needles is not just about material; it's about understanding the specific requirements of your application." This underscores the importance of making informed decisions when it comes to these essential parts.

As we look ahead to 2025, the landscape for bearing needles continues to evolve with advancements in technology and materials science. Engineers and manufacturers face the challenge of navigating a plethora of options, each boasting different specifications and benefits. It's crucial to grasp the nuances that differentiate these bearing needles to enhance efficiency and prevent premature wear and tear in machinery.

This guide aims to illuminate the path to selecting the best bearing needles for your specific needs, laying out considerations such as load capacity, friction characteristics, and environmental factors. By leveraging expert insights and the latest industry trends, readers will be better equipped to make the right choice, ensuring optimal performance and longevity of their mechanical systems.

Understanding Bearing Needles: Types and Functions

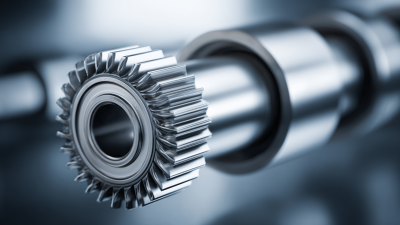

Bearing needles are essential components in various machinery, providing efficiency and reducing wear in moving parts. Primarily found in applications such as engines and industrial equipment, these small metal pins are designed to accommodate rotating elements like shafts and gears. Their main function is to reduce friction, facilitate smooth movement, and handle radial and axial loads effectively. Understanding the different types of bearing needles can help in selecting the right ones for specific applications.

There are several types of bearing needles, each designed for distinct functions. Needle roller bearings are among the most common; they feature a high length-to-diameter ratio, which makes them ideal for applications where space is limited. They distribute loads evenly across their surface, minimizing stress on contact areas. Additionally, there are caged needle roller bearings, which incorporate a retainer to guide the needles and prevent them from colliding with each other, thus enhancing performance and longevity. Understanding these types and their respective advantages enables users to make informed decisions when selecting bearing needles for optimal performance in their machinery.

Key Factors to Consider When Choosing Bearing Needles

When selecting bearing needles, several key factors should be taken into consideration to ensure optimal performance and longevity in their applications. First and foremost is the material composition. High-quality bearing needles are typically constructed from hardened steel or stainless steel, which are essential for resisting wear and tear under heavy loads. According to a report by ResearchAndMarkets, the bearing market is projected to grow at a compound annual growth rate (CAGR) of 5.5% through 2025, emphasizing the significance of investing in durable materials for enhanced mechanical efficiency.

Another critical factor is the load rating and maximum operating speed of the bearing needles. The load rating specifies how much weight the needle can support without failing, while the maximum operating speed indicates how fast the needle can rotate without overheating. Data from the Global Industry Analysts suggests that the increased performance demands across various industries, such as automotive and aerospace, underscore the importance of precise specifications. Users should ensure they choose bearing needles that exceed the required load and speed ratings for their applications, as this can substantially decrease the risk of premature failure.

Furthermore, the lubrication method is an often-overlooked aspect of bearing needle selection. Proper lubrication can significantly reduce friction and heat buildup, extending the life of the needles. Research indicates that up to 30% of bearing failures can be attributed to inadequate lubrication, making it imperative to select a needle type that is compatible with the chosen lubrication system. Keeping these key factors in mind will not only lead to improved operational efficiency but also enhance the overall reliability of machinery in demanding environments.

Comparative Analysis of Bearing Needle Materials

When selecting bearing needles, the material composition plays a vital role in determining their performance and durability. Common materials used in manufacturing bearing needles include stainless steel, high-carbon steel, and polymer composites. Stainless steel is widely preferred for its excellent corrosion resistance and strength, making it suitable for applications in harsh environments. Its ability to withstand high temperatures and pressures further enhances its suitability for various industrial applications. However, the processing cost tends to be higher compared to other materials, which can be a consideration for cost-sensitive projects.

High-carbon steel bearings, on the other hand, offer superior hardness and wear resistance, resulting in longer service life under load. They are often treated with additional finishes to improve their resistance to rust and fatigue. While they excel in strength, these materials may not be ideal for applications exposed to moisture unless properly treated. Polymer composite bearings, while generally less robust, provide lightweight solutions and excellent noise-dampening properties. These materials are often used in applications where weight savings and vibration reduction are critical, such as in automotive and aerospace industries. Understanding the nuanced differences between these materials is essential for making informed decisions when choosing bearing needles for specific applications.

Top Brands and Products in the Bearing Needle Market for 2025

When navigating the bearing needle market in 2025, it's vital to understand the top brands and products that will shape the industry. Leading manufacturers have harnessed advanced engineering techniques and materials, ensuring their bearing needles deliver enhanced performance and durability. These brands prioritize innovation, focusing on the latest manufacturing processes that increase efficiency while reducing wear and tear. As a result, consumers can expect improved product lifespan and reliability, which are crucial factors in various applications, from automotive to industrial machinery.

In addition to technological advancements, the best products on the market are designed with versatility in mind. A range of sizes and styles offers options tailored to specific needs, making it easier for users to find the perfect fit for their projects. Furthermore, sustainability has become a significant consideration, with some brands adopting eco-friendly practices in their production processes. By acknowledging the market trends and evaluating the offerings of top brands, buyers can make informed choices that reflect their performance requirements and environmental values, ensuring they select the best bearing needles available.

Future Trends in Bearing Needle Technology and Innovations

In recent years, bearing needle technology has witnessed significant advancements, and 2025 is poised to usher in even more innovative trends. One prominent direction is the integration of smart technology into needle bearings. These intelligent systems enable real-time monitoring of performance metrics, such as temperature and load, which allows for predictive maintenance and enhanced operational efficiency. By harnessing data analytics, manufacturers can optimize performance and identify potential issues before they lead to failures, thereby reducing downtime and maintenance costs.

Another key trend is the emphasis on sustainability in the production and use of bearing needles. As industries worldwide strive to minimize their environmental impact, manufacturers are focusing on developing eco-friendly materials and processes. Biodegradable lubricants and recyclable components are examples of innovations aimed at creating a greener bearing needle. Additionally, advancements in manufacturing technologies, such as additive manufacturing, allow for the reduction of waste and energy consumption during production. This shift towards sustainability not only addresses environmental concerns but also meets the growing demand for eco-conscious solutions across various sectors, including automotive and aerospace.

The Ultimate Guide to Choosing the Best Bearing Needles in 2025

| Type | Material | Load Capacity (kg) | Operating Temperature (°C) | Average Lifespan (Hours) | Future Trends |

|---|---|---|---|---|---|

| Cylindrical | Stainless Steel | 200 | -20 to 100 | 50000 | Eco-friendly materials |

| Needle Roller | Bronze | 150 | -10 to 80 | 60000 | Smart bearings with RFID |

| Thrust | Polymer | 100 | -30 to 90 | 40000 | Self-lubricating designs |

| Spherical | Carbon Steel | 250 | -20 to 120 | 70000 | Enhanced corrosion resistance |

| Needle Bearings | Ceramic | 180 | -40 to 150 | 80000 | Nanotechnology applications |

Related Posts

-

Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

-

2025 Top Needle Bearing Trends: What You Need to Know for Optimal Performance

-

Understanding Pillow Bearings: Essential Insights for Engineers and DIY Enthusiasts

-

7 Essential Tips for Choosing the Best Pillar Bearing for Your Needs

-

Forecasting the Brake Bearings Market Growth Amidst the 138th China Import and Export Fair in 2025

-

How to Diagnose and Fix Common Tyre Bearing Issues in Your Vehicle