Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

In the realm of mechanical engineering, enhancing efficiency and performance is paramount, and one of the pivotal components in achieving this is the groove bearing. Groove bearings are increasingly recognized for their ability to reduce friction and improve load distribution, which is critical in various industrial applications. According to a recent industry report by MarketsandMarkets, the global bearing market is projected to reach $92.19 billion by 2025, with a significant segment attributed to advanced bearing technologies like groove bearings. These bearings not only facilitate smoother motion but also contribute to longer equipment life and reduced maintenance costs. As industries continuously seek ways to optimize operational performance, understanding the mechanics and advantages of groove bearings becomes essential. This article delves into the intricacies of groove bearing technology, providing essential insights that promise to enhance mechanical efficiency across diverse applications.

How Groove Bearings Operate: The Mechanics Behind Their Performance

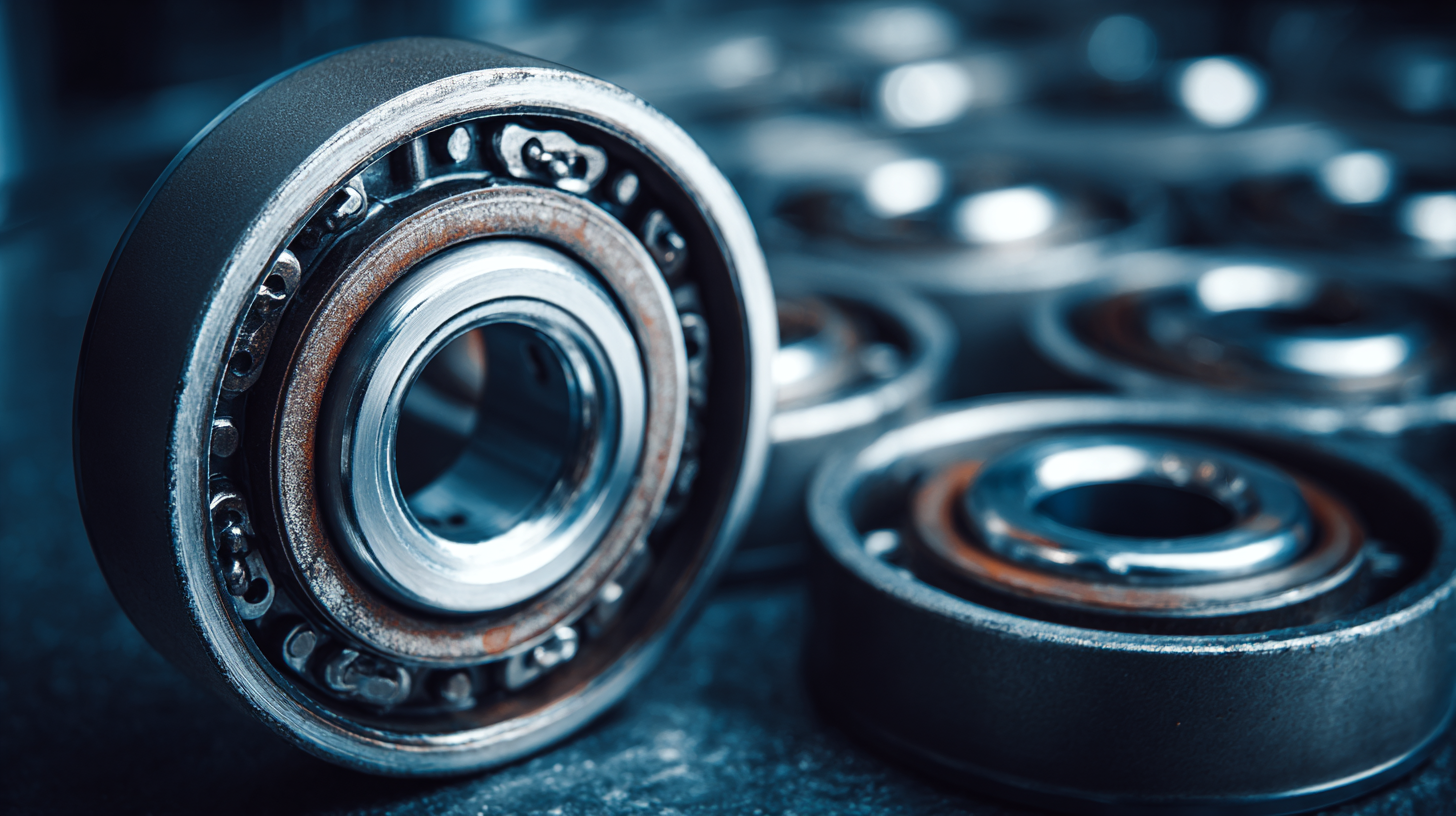

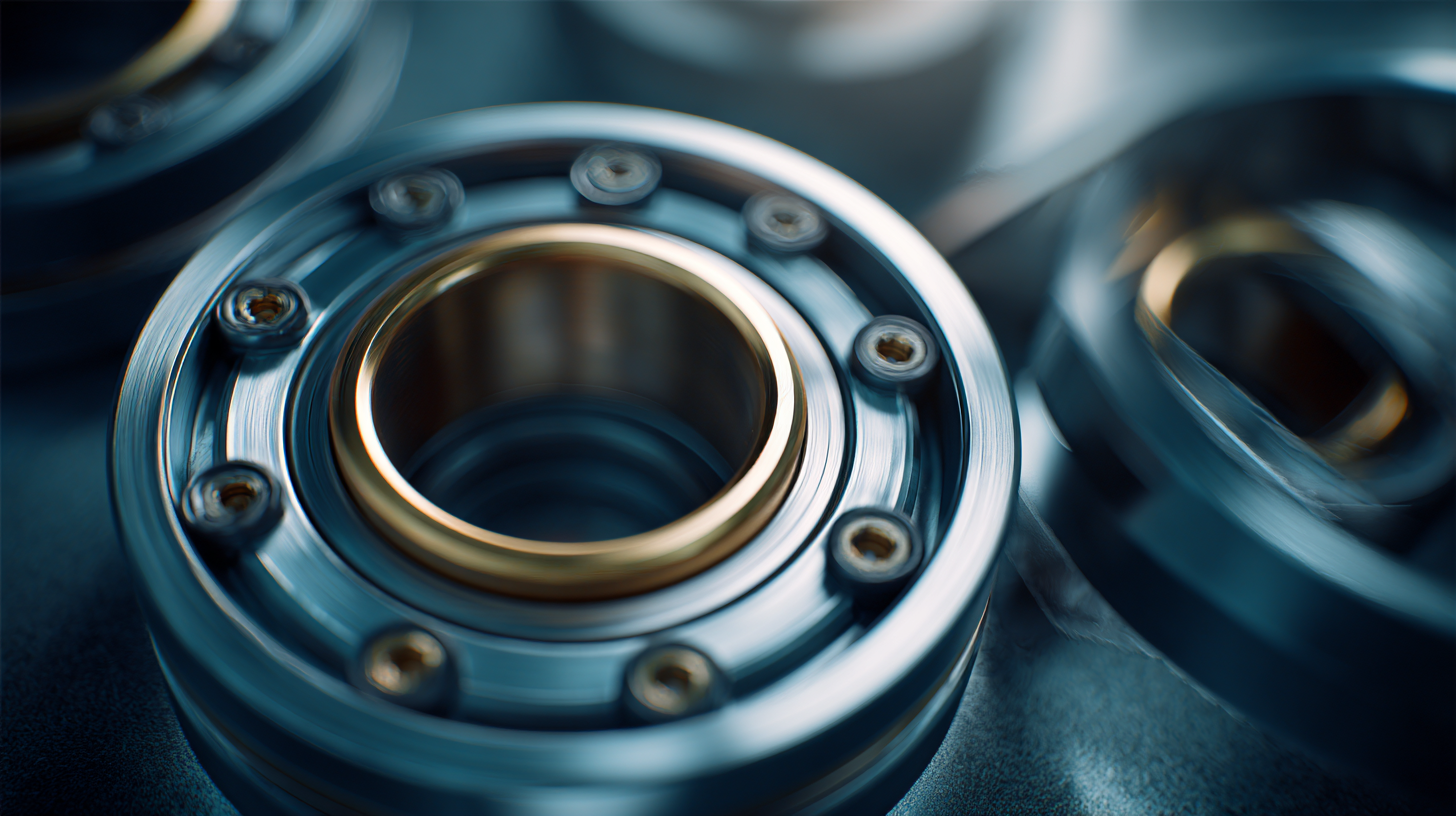

Groove bearings are pivotal components in numerous mechanical applications, playing a crucial role in reducing friction and facilitating smooth rotation. These bearings operate based on a simple yet effective principle: the grooves help distribute the load evenly across the bearing surface, minimizing contact area and thereby diminishing wear and tear. The design of these grooves allows for a lubricant to be effectively retained, enhancing the bearing's efficiency and longevity. The interaction between the bearing surfaces is finely tuned, which enables a fine balance between stability and mobility in machinery.

The mechanics behind groove bearings involve the careful consideration of material properties and geometric configurations. Different groove patterns can be engineered to optimize performance for specific applications, whether in high-speed machinery or heavy-duty environments. The grooves themselves can vary in depth and profile, influencing parameters such as load capacity and resistance to axial misalignment. By understanding these mechanics, engineers can tailor groove bearings to meet the precise demands of their systems, ultimately leading to improved mechanical performance and reduced maintenance costs.

Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Load Distribution | Groove bearings provide a more even load distribution across their surfaces. | Reduced wear and prolonged lifespan. | Industrial machinery, automotive components. |

| Friction Reduction | Designed to minimize friction between moving parts. | Improved energy efficiency and performance. | Robotics, conveyor systems. |

| Temperature Control | Engineered to dissipate heat effectively during operation. | Enhanced reliability under high-stress conditions. | High-performance engines, aerospace systems. |

| Versatility | Compatible with various types of machinery and environments. | Widely applicable across industries. | Manufacturing, mining, and transportation. |

| Maintenance | Low maintenance requirements due to durable construction. | Cost savings and reduced downtime. | Heavy equipment, agricultural machines. |

Key Types of Groove Bearings: Selection Criteria for Optimal Applications

Groove bearings play a crucial role in a wide range of mechanical applications, offering vital support and reducing friction. When selecting the optimal groove bearing, several key criteria should be considered, including load capacity, material compatibility, and operational environment. According to a report by the International Bearing Association, the global market for bearings, including groove types, is expected to reach $105 billion by 2025. This underscores the importance of choosing the right bearing to enhance performance and reliability in machinery.

In particular, the selection between radial and axial groove bearings can significantly impact operational efficiency. Radial groove bearings are ideal for applications requiring high load support with minimal radial space, while axial groove bearings excel in applications where thrust loads are prevalent. A study from the Journal of Mechanical Engineering noted that inappropriate bearing selection could lead to a 35% increase in wear and a corresponding decrease in machine durability. Therefore, understanding the specific demands of the application is essential for maintaining mechanical efficiency and prolonging the lifespan of equipment.

Maintenance Practices for Groove Bearings: Ensuring Longevity and Reliability

Maintaining groove bearings is crucial for ensuring their longevity and reliability in various industrial applications. These bearings are prevalent due to their ability to support both radial and axial loads, making them a staple in machinery that demands high efficiency. Regular maintenance practices, such as monitoring lubrication levels and conducting periodic inspections, can significantly enhance the performance of groove bearings. For instance, checking for signs of wear can prevent more severe issues, such as vibration caused by faults, which can lead to catastrophic failures if left unaddressed.

Moreover, implementing a vibrational analysis can provide critical insights into the condition of deep-groove ball bearings under radial loads. This analytical approach helps in identifying potential faults early on, thus allowing for timely interventions. By integrating these maintenance practices, operators can ensure that groove bearings function optimally, reducing downtime and extending the overall lifespan of the machinery. A proactive maintenance strategy is essential not only for the reliability of groove bearings but also for the overall efficiency of mechanical systems where they play a pivotal role.

Common Issues with Groove Bearings: Troubleshooting Tips and Solutions

Groove bearings are essential components in many mechanical systems, but they can encounter specific issues that may hinder their performance. One common problem is excessive wear due to insufficient lubrication. When the lubricant is not evenly distributed or fails to reach the bearing surfaces, friction increases, leading to premature failure. To address this, regular maintenance checks are crucial, along with ensuring that the lubrication system is functioning correctly and that the lubricant being used is suitable for the operational conditions.

Another prevalent issue with groove bearings is misalignment, which can lead to uneven load distribution and increased stress on the bearing surfaces. This misalignment can stem from improper installation or shifting of components during operation. To troubleshoot this issue, it's essential to perform regular alignment checks and make necessary adjustments to ensure that the bearing is properly aligned within the assembly. Additionally, monitoring vibration levels can help identify misalignment early, allowing for timely intervention before significant damage occurs. By being proactive about these common problems, the overall efficiency and longevity of groove bearings can be significantly enhanced.

Innovative Technologies in Groove Bearings: Enhancing Efficiency in Modern Systems

Innovative technologies in groove bearings play a crucial role in improving mechanical efficiency within modern systems. These bearings, designed to reduce friction and handle various loads, are being enhanced by advanced materials and engineering techniques. For instance, the incorporation of composite materials in the design of groove bearings not only reduces weight but also increases durability and resistance to wear. This innovation has made them particularly suitable for high-performance applications in industries ranging from aerospace to automotive.

Innovative technologies in groove bearings play a crucial role in improving mechanical efficiency within modern systems. These bearings, designed to reduce friction and handle various loads, are being enhanced by advanced materials and engineering techniques. For instance, the incorporation of composite materials in the design of groove bearings not only reduces weight but also increases durability and resistance to wear. This innovation has made them particularly suitable for high-performance applications in industries ranging from aerospace to automotive.

Moreover, the development of smart groove bearings equipped with sensors allows for real-time monitoring of performance metrics. By integrating IoT technology, these bearings can provide valuable data regarding load distribution, temperature changes, and overall health status. This predictive maintenance capability not only minimizes downtime but also extends the lifespan of machinery, leading to significant cost savings. As the demand for efficiency and reliability continues to grow, the advancements in groove bearings exemplify how innovative technologies can transform traditional mechanical systems into highly efficient and intelligent operations.

Related Posts

-

How to Optimize Your Projects with Tape Bearing Solutions

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

How to Choose the Right Tapped Bearing for Your Application Needs

-

7 Essential Tips for Choosing the Best Pillar Bearing for Your Needs

-

How to Choose the Right Deep Bearing for Your Industrial Needs

-

How to Choose the Right Tyre Bearing for Your Vehicle Needs