The Future of Groove Bearings in Sustainable Engineering Solutions

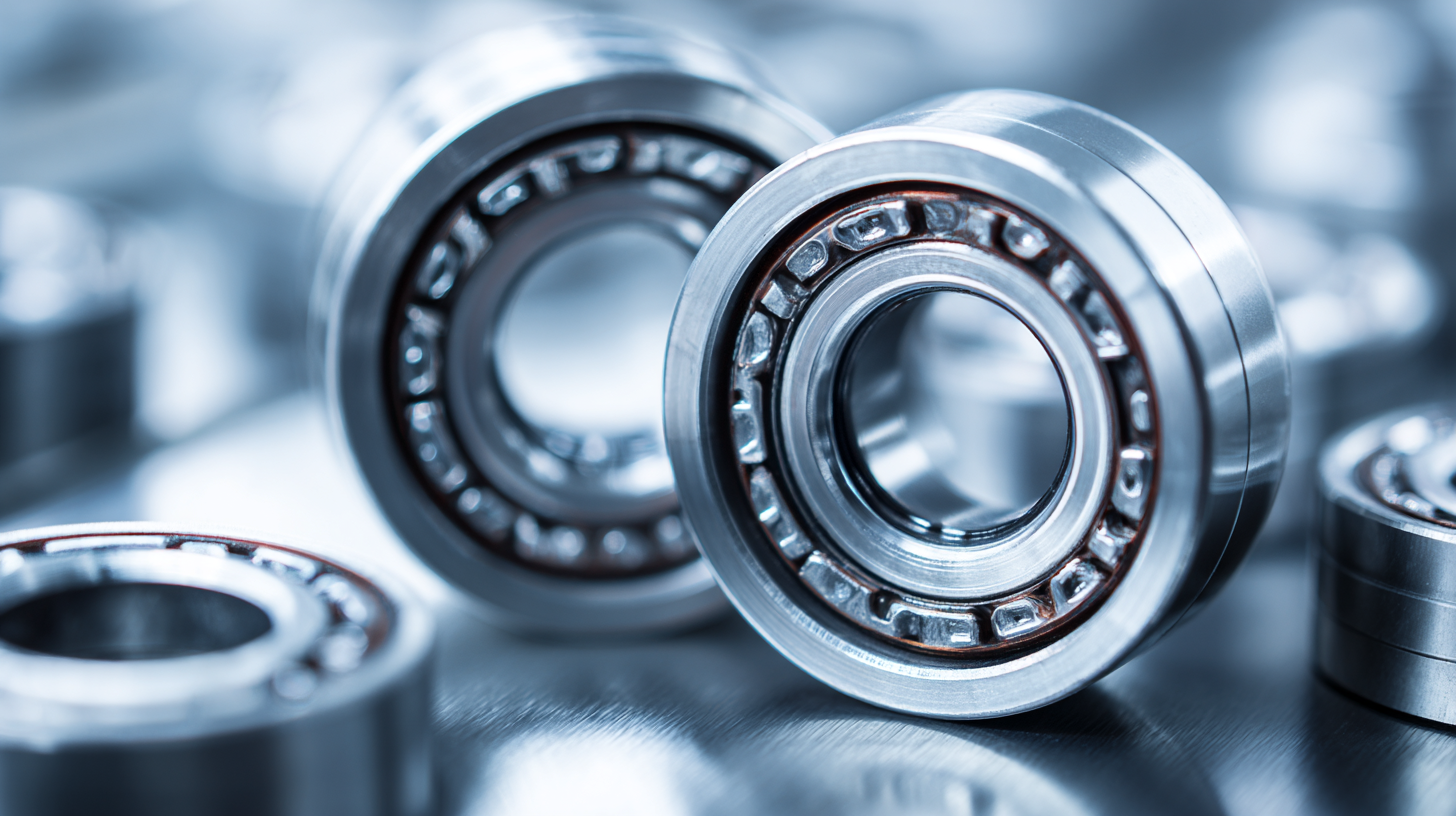

In the evolving landscape of sustainable engineering solutions, Groove Bearings stand out as a pivotal component in enhancing machinery performance while addressing environmental concerns. According to a report by MarketsandMarkets, the global bearing market is projected to reach $105 billion by 2025, with a significant push towards innovative designs that cater to sustainability. Groove Bearings, with their intricately designed geometries, allow for reduced friction and wear, contributing to energy efficiency—an essential factor in today's eco-conscious manufacturing processes.

In the evolving landscape of sustainable engineering solutions, Groove Bearings stand out as a pivotal component in enhancing machinery performance while addressing environmental concerns. According to a report by MarketsandMarkets, the global bearing market is projected to reach $105 billion by 2025, with a significant push towards innovative designs that cater to sustainability. Groove Bearings, with their intricately designed geometries, allow for reduced friction and wear, contributing to energy efficiency—an essential factor in today's eco-conscious manufacturing processes.

As industries strive to meet stringent sustainability targets, the adoption of advanced Groove Bearing technologies is essential. Research from the International Journal of Precision Engineering and Manufacturing highlights that using high-performance Groove Bearings can lead to a 30% increase in operational efficiency and a corresponding decrease in energy consumption. This aligns with global efforts to minimize carbon footprints and improve overall resource utilization.

Thus, the future of Groove Bearings is not merely about mechanical advancement but is also intrinsically linked to the broader narrative of sustainable engineering. By optimizing bearing systems for enhanced performance and lower environmental impact, engineers can play a critical role in developing solutions that are both economically viable and environmentally friendly, paving the way for a greener industrial future.

Exploring the Role of Groove Bearings in Eco-Friendly Engineering Practices

In the realm of sustainable engineering, groove bearings are emerging as crucial components that support eco-friendly practices. These bearings not only enhance the efficiency of mechanical systems but also contribute to reducing energy consumption and waste. By utilizing innovative materials and designs, groove bearings can be engineered to minimize friction and improve performance in various applications, making them indispensable for eco-conscious builders and manufacturers.

The integration of groove bearings into sustainable projects aligns with a broader movement towards environmentally responsible engineering solutions. As seen in recent trends across industries—from sustainable siding profiles to the revival of music through eco-friendly methods—there is a growing recognition of the importance of green technologies. This shift is not just about innovation; it's about fostering a holistic approach to sustainability that prioritizes the planet. In this context, groove bearings represent a vital link in the chain of sustainable engineering practices, proving that high-performance components can coexist with environmental stewardship.

The Future of Groove Bearings in Sustainable Engineering Solutions

| Dimension | Material | Sustainability Score (1-10) | Applications | Lifecycle Impact (Years) |

|---|---|---|---|---|

| 20mm x 40mm | Recycled Steel | 8 | Renewable Energy | 15 |

| 25mm x 50mm | Biodegradable Plastics | 9 | Solar Panel Manufacturing | 12 |

| 30mm x 60mm | Aluminum Alloys | 7 | Wind Turbines | 18 |

| 35mm x 70mm | Composite Materials | 10 | Electric Vehicles | 20 |

| 40mm x 80mm | Sustainable Alloys | 8 | Hydroelectric Systems | 25 |

Innovative Materials for Enhancing Groove Bearings in Sustainable Designs

The emergence of innovative materials is crucial for enhancing groove bearings in sustainable engineering designs. Traditional materials often fail to meet the growing demands for efficiency and eco-friendliness in modern applications. As engineers and designers strive for solutions that reduce environmental impact, they are increasingly turning to advanced composites and bio-based materials. These alternatives not only provide excellent performance but also contribute to minimizing the carbon footprint associated with production and disposal.

Incorporating these innovative materials into groove bearings can significantly improve their lifespan and reliability. For instance, lightweight composites can reduce energy consumption in machinery, while self-lubricating materials decrease the need for harmful lubricants. Additionally, the use of recyclable materials in the production of groove bearings supports a circular economy approach, where resources are used more efficiently and waste is minimized. As the industry pivots towards sustainability, these material advancements will redefine the performance and applicability of groove bearings, paving the way for a greener future in engineering.

The Future of Groove Bearings in Sustainable Engineering Solutions

Adopting Groove Bearings to Improve Energy Efficiency in Mechanical Systems

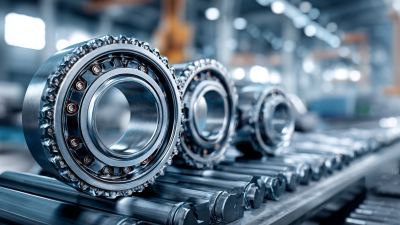

The adoption of groove bearings in mechanical systems is increasingly being recognized as a critical factor in enhancing energy efficiency. According to recent market analysis, the global large-scale bearing market is valued at approximately USD 20.42 billion in 2025, with a projected growth rate of 6.1% CAGR through 2035. This substantial growth is driven by the rising demand for energy-efficient solutions across various industries, where groove bearings play a pivotal role.

Groove bearings, particularly deep-groove ball bearings, offer reduced friction and improved load capacity, making them ideal for applications where energy efficiency is essential. As outlined in the Europe Ball Bearing Market growth report, the segmentation by bearing type reveals a notable trend toward the use of self-aligning ball bearings and deep-groove variants, which further supports sustainable engineering practices. By integrating these bearings into mechanical systems, industries can not only improve performance but also contribute to a reduction in overall energy consumption, aligning with global sustainability goals.

Strategies for Integrating Groove Bearings in Green Technology Projects

The integration of groove bearings into green technology projects is a vital step towards sustainable engineering solutions. As industries prioritize eco-friendly innovations, groove bearings emerge as versatile components that enhance operational efficiency while minimizing environmental impact. Recent reports indicate that advancements in groove bearing materials and designs can significantly reduce energy consumption and greenhouse gas emissions in manufacturing processes. With the global renewable energy market projected to reach $1.5 trillion by 2025, the demand for reliable and sustainable components like groove bearings continues to rise.

Tips: Consider collaborating with material scientists to explore lightweight and biodegradable materials for groove bearings, which can further reduce the carbon footprint of engineering solutions. Additionally, focus on creating robust maintenance protocols to extend the lifespan of bearings, thereby contributing to waste reduction.

Countries like China are making remarkable strides in innovation, moving towards self-sufficiency in advanced industries. The WIPO GREEN City Acceleration Project emphasizes the importance of intellectual property in supporting green technology initiatives. By strategically integrating groove bearings into projects focused on renewable energy and sustainable infrastructure, engineers can help position their companies at the forefront of this transformation while aligning with global decarbonization goals.

Future Trends in Groove Bearing Manufacturing for Sustainable Applications

As the demand for sustainable engineering solutions grows, the future trends in groove bearing manufacturing are poised for significant evolution. The global bearings market is projected to experience substantial growth, expanding from USD 50.16 billion in 2025 to an impressive USD 97.10 billion by 2030. This surge is largely driven by industries seeking to enhance energy efficiency and reduce environmental impact.

One of the critical trends is the shift towards eco-friendly materials in groove bearing production. Manufacturers are increasingly exploring biodegradable and recyclable materials to minimize waste and improve the lifecycle of bearings. Moreover, advancements in manufacturing technologies, such as additive manufacturing and automation, are enabling the production of lightweight and highly durable groove bearings that require less energy to operate.

Tips for selecting sustainable groove bearings include thoroughly evaluating the materials used in their construction and considering the manufacturer’s commitment to environmental practices. Additionally, it’s beneficial to look for bearings that promote energy efficiency and can easily be recycled at the end of their service life. By prioritizing these factors, businesses can contribute to a more sustainable future while still meeting their operational needs.

Related Posts

-

Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

7 Essential Tips for Choosing the Best Pillar Bearing for Your Needs

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

Exploring Opportunities for Auto Bearings at the 138th Canton Fair 2025: Industry Trends and Insights

-

How to Choose the Right Pillow Bearing for Your Industrial Applications