10 Facts About Real Bearing for Optimal Performance in Your Machinery

In today's competitive manufacturing landscape, the selection of the right components is crucial for optimizing machinery performance, and one of the most critical elements is the use of Real Bearings. According to a report by the International Journal of Advanced Manufacturing Technology, approximately 30% of machinery failures can be attributed to bearing issues, underscoring the importance of understanding the nuances of bearing selection and maintenance.

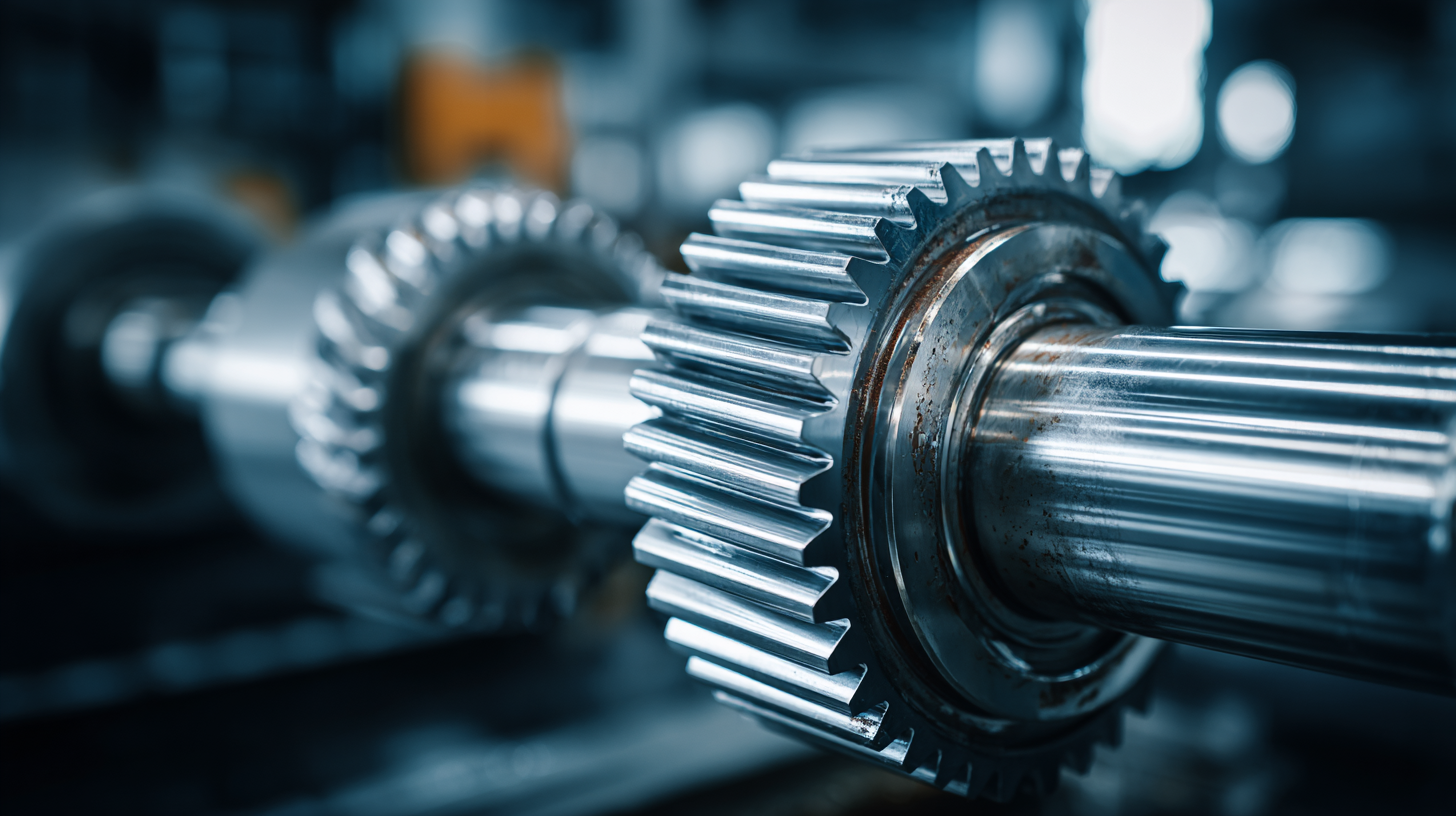

These high-performance components not only enhance the operational efficiency of machines but also significantly extend their service life. Real Bearings play a vital role in reducing friction, managing heat, and supporting heavy loads, which, in turn, leads to improved productivity and reduced downtime. Thus, gaining insight into essential facts about Real Bearings is paramount for engineers and technicians aiming to achieve optimal machinery performance and reliability.

Understanding the Importance of Real Bearings in Machinery Performance

Real bearings play a critical role in optimizing machinery performance, significantly impacting efficiency, reliability, and operational costs. According to a report by the International Journal of Advances in Mechanical Engineering, the correct selection and implementation of bearings can improve machinery efficiency by up to 15%. This increase in efficiency stems from reduced friction and enhanced load-bearing capabilities, which are essential for the longevity of machinery. In high-performance applications, even a minor improvement in bearing performance can lead to significant cost savings and reduced downtime.

Furthermore, effective maintenance of real bearings is crucial for maintaining optimal performance. The National Lubricating Grease Institute (NLGI) states that improper lubrication of bearings can lead to premature failure, accounting for nearly 36% of all bearing failures in industrial applications. Regular monitoring and preventive maintenance can mitigate these risks, ensuring the machinery runs smoothly and efficiently. By prioritizing the quality and maintenance of real bearings, industries can achieve not only enhanced performance but also prolonged machinery life, reinforcing their overall productivity and profitability.

10 Facts About Real Bearings for Optimal Performance in Machinery

This chart illustrates various performance metrics important for real bearings in machinery. The values represent the capabilities and characteristics that impact the efficiency and longevity of bearings in different applications.

Key Factors Influencing Bearing Selection for Optimal Operations

When selecting bearings for optimal performance in machinery, several key factors must be considered to ensure efficiency and reliability. According to a report by the International Organization for Standardization (ISO), lubrication is one of the critical elements influencing bearing selection. Proper lubrication not only reduces friction but also minimizes wear and heat generation, which is crucial for extending bearing life. Research indicates that over 40% of bearing failures in industrial applications can be attributed to inadequate lubrication, underlining the importance of this factor.

Another fundamental consideration is the load capacity. A study published by the American Bearing Manufacturers Association (ABMA) highlights that selecting bearings with appropriate load ratings can enhance machine performance and decrease the likelihood of fatigue and failure. It is recommended that engineers assess both static and dynamic load conditions to choose the most suitable bearing type for their specific application. Furthermore, environmental conditions—such as temperature, humidity, and potential exposure to contaminants—play a significant role in deciding the bearing materials and designs. Properly accounting for these factors can lead to substantial improvements in operational efficiency, making informed bearing selection an essential practice in machinery management.

The Role of Load Ratings and Dynamic Capacity in Bearing Efficiency

When it comes to optimizing the performance of machinery, understanding the

load ratings

and

dynamic capacity

of bearings is essential. Load ratings indicate the maximum weight that a bearing can support while still functioning effectively.

They are typically categorized into basic dynamic load ratings, which account for the forces acting on the bearing during operation, and

static load ratings, which apply when loads are not in motion. Knowing these ratings helps engineers select the right bearing for particular applications,

ensuring reliability and longevity under various operating conditions.

Dynamic capacity, on the other hand, refers to the bearing’s ability to support loads while in motion without leading to excessive wear or failure.

It is a critical factor that influences the design and selection of bearings for high-speed or heavily loaded applications.

Bearings with higher dynamic capacity are capable of handling greater loads and operating at higher speeds, thus enhancing the overall efficiency and performance of machinery.

A careful assessment of both load ratings and dynamic capacity allows for the selection of bearings that not only meet the demands of the application but also help minimize

maintenance costs and

downtime.

Maintenance Strategies to Enhance Bearing Lifespan and Performance

To enhance the lifespan and performance of bearings in machinery, implementing effective maintenance strategies is crucial. Regular inspection of bearings can prevent unexpected failures and extend their operational life. This includes checking for signs of wear, ensuring proper lubrication, and monitoring temperature and vibration levels. By maintaining optimal operating conditions, issues can be identified early, allowing for timely interventions.

Incorporating a proactive maintenance schedule is also essential. This may involve the use of predictive maintenance tools, which utilize data analytics to forecast potential problems before they arise. Additionally, ensuring that bearings are installed correctly and aligned properly can significantly reduce the risk of failure. Utilizing high-quality lubricants tailored to specific operational conditions can further enhance performance, as they help minimize friction and heat generation. By prioritizing these maintenance strategies, machinery operators can achieve optimal bearing performance and reliability.

Industry Standards and Innovations in Bearing Technology for Improved Reliability

The advancements in bearing technology are crucial for enhancing the reliability and efficiency of machinery across various industries. Innovative solutions such as cutting-edge bonding techniques are paving the way for bearings that not only last longer but also perform significantly better under operational stress. For instance, the integration of advanced materials and design methodologies allows for bearings that can withstand harsh environments and high loads, ultimately improving machinery uptime.

The advancements in bearing technology are crucial for enhancing the reliability and efficiency of machinery across various industries. Innovative solutions such as cutting-edge bonding techniques are paving the way for bearings that not only last longer but also perform significantly better under operational stress. For instance, the integration of advanced materials and design methodologies allows for bearings that can withstand harsh environments and high loads, ultimately improving machinery uptime.

Additionally, adherence to evolving industry standards is essential for ensuring these innovations deliver on their promises. Manufacturers are continuously updating their specifications to align with new performance metrics, ensuring that bearings meet stringent reliability requirements. These developments reflect a shift towards more sustainable practices, as improved bearing technology contributes to reduced maintenance needs and longer service intervals, resulting in less resource consumption and waste. Embracing these innovative bearing solutions positions companies to achieve optimal performance while simultaneously contributing to their sustainability goals.

Related Posts

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

10 Essential Tips for Choosing the Perfect Tapped Bearing

-

7 Essential Tips for Choosing the Right Rear Bearing for Your Production Needs

-

How to Choose the Right Tapped Bearing for Your Application Needs

-

How to Choose the Right Pillar Bearing for Your Industrial Needs

-

How to Choose the Right Needle Rollers for Your Mechanical Applications