7 Essential Tips for Choosing the Right Rear Bearing for Your Production Needs

In the manufacturing sector, selecting the appropriate components is crucial for operational efficiency and product quality, particularly when it comes to rear bearings. According to a recent market analysis by Grand View Research, the global bearings market is projected to reach USD 99.2 billion by 2025, with a significant portion driven by advancements in material sciences and engineering. As industries evolve, the demand for high-performance rear bearings that can withstand harsh conditions while minimizing downtime becomes paramount. Factors such as load capacity, lubrication type, and operating speed must be taken into consideration. This blog will provide seven essential tips to help you navigate the complexities of choosing the right rear bearing for your production needs, ensuring reliability and efficiency in your operations.

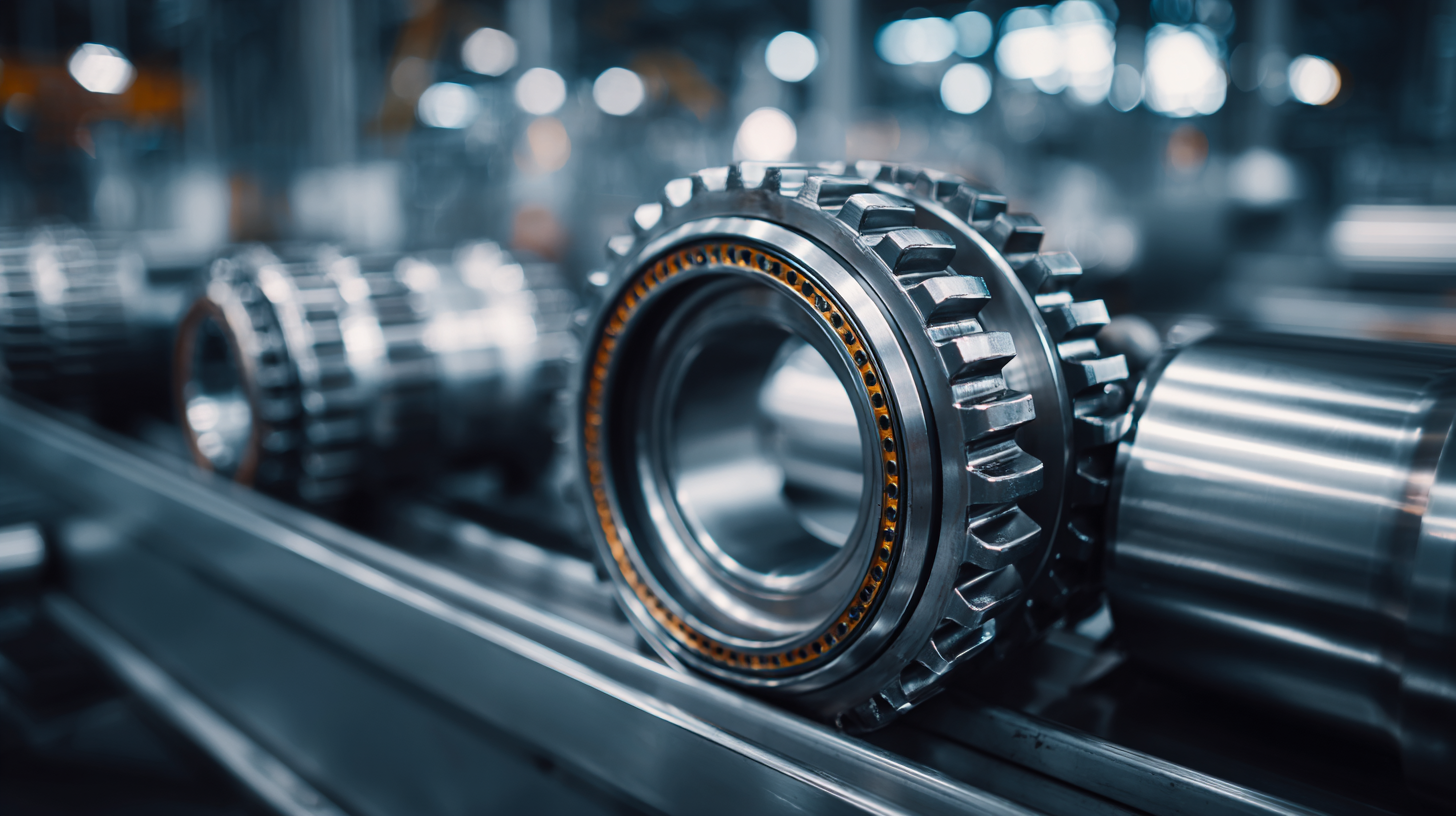

Understanding Rear Bearings: Key Types and Their Applications

Rear bearings play a crucial role in the performance and longevity of various machinery, particularly in automotive and industrial applications. Common types of rear bearings include ball bearings, roller bearings, and tapered bearings. According to a recent industry analysis by Research and Markets, the global bearings market is expected to reach $101 billion by 2025, driven by the growing demand for precision-engineered components in automobile manufacturing and machinery design. Each bearing type presents unique advantages for specific applications. For instance, ball bearings are known for their ability to handle radial loads and are ideal for high-speed machinery, whereas roller bearings are better suited for heavy axial loads and require less maintenance.

Understanding the specific requirements of your operational environment is key to selecting the right rear bearing. Factors such as load capacity, rotational speed, and temperature resistance can influence the performance and durability of the bearings. A study published by the American Society of Mechanical Engineers highlights that improper bearing selection can lead to premature failure, resulting in costly downtime—indicating that choosing the right type, based on detailed application needs, is integral to maintaining productivity. For example, tapered roller bearings are often utilized in automotive wheel hubs due to their ability to handle both radial and axial loads simultaneously, demonstrating the importance of aligning bearing characteristics with intended use.

7 Essential Tips for Choosing the Right Rear Bearing for Your Production Needs

| Bearing Type | Application | Load Capacity (kg) | Speed Rating (RPM) | Material |

|---|---|---|---|---|

| Ball Bearing | General Purpose | 1000 | 3000 | Steel |

| Roller Bearing | Heavy Duty | 2000 | 2500 | Chrome Steel |

| Spherical Bearing | Automotive | 1500 | 1800 | Stainless Steel |

| Thrust Bearing | Rotating Equipment | 1200 | 2200 | Bronze |

| Needle Bearing | Compact Spaces | 800 | 3200 | Alloy Steel |

| Magnetic Bearing | High Speed | Variable | 50000 | Non-Metallic |

Factors to Consider When Selecting Rear Bearings for Production

When selecting rear bearings for your production needs, it's crucial to consider several key factors that can significantly impact performance and durability. One of the first aspects to evaluate is the load capacity of the bearing. Ensure that the chosen bearing can withstand the friction and stress it will encounter during operation, especially in high-load applications. Additionally, the material and lubrication of the bearing play a vital role in its longevity and efficiency. Choose materials that are resistant to wear and compatible with the operating environment to minimize maintenance and downtime.

Another tip is to analyze the operating temperature range of the bearings. High temperatures can lead to premature failure, so selecting bearings rated for high-temperature applications is essential if your production process generates significant heat. Furthermore, consider the environmental conditions, such as moisture and debris, which can affect bearing performance. Opt for sealed or shielded bearings in harsh environments to protect them from contaminants and extend their lifespan.

In summary, making an informed decision about rear bearings involves understanding their load capacity, material compatibility, operating temperature, and environmental conditions. By focusing on these factors, you can choose the right bearings that will enhance the efficiency and reliability of your production processes.

The Importance of Load Capacity in Rear Bearing Selection

When selecting rear bearings for production applications, load capacity is a critical factor that cannot be overlooked. In industrial settings, bearings are subjected to a variety of loads, including static and dynamic loads, which can significantly affect their performance and lifespan. According to a 2021 report by the American Bearing Manufacturers Association (ABMA), approximately 70% of bearing failures are due to inadequate load capacity, highlighting the need for precise calculations during the selection process.

To ensure optimal performance, it is essential to understand the load requirements of your specific application. Bearings are rated for both radial and axial load capacities, which must be carefully evaluated based on operational conditions. For instance, a recent study from the International Journal of Mechanical Engineering revealed that applying loads exceeding the nominal rating could result in a 50% reduction in the bearing's lifespan. Therefore, selecting bearings with adequate load capacity not only improves reliability but can also lead to significant cost savings by reducing downtime and maintenance needs.

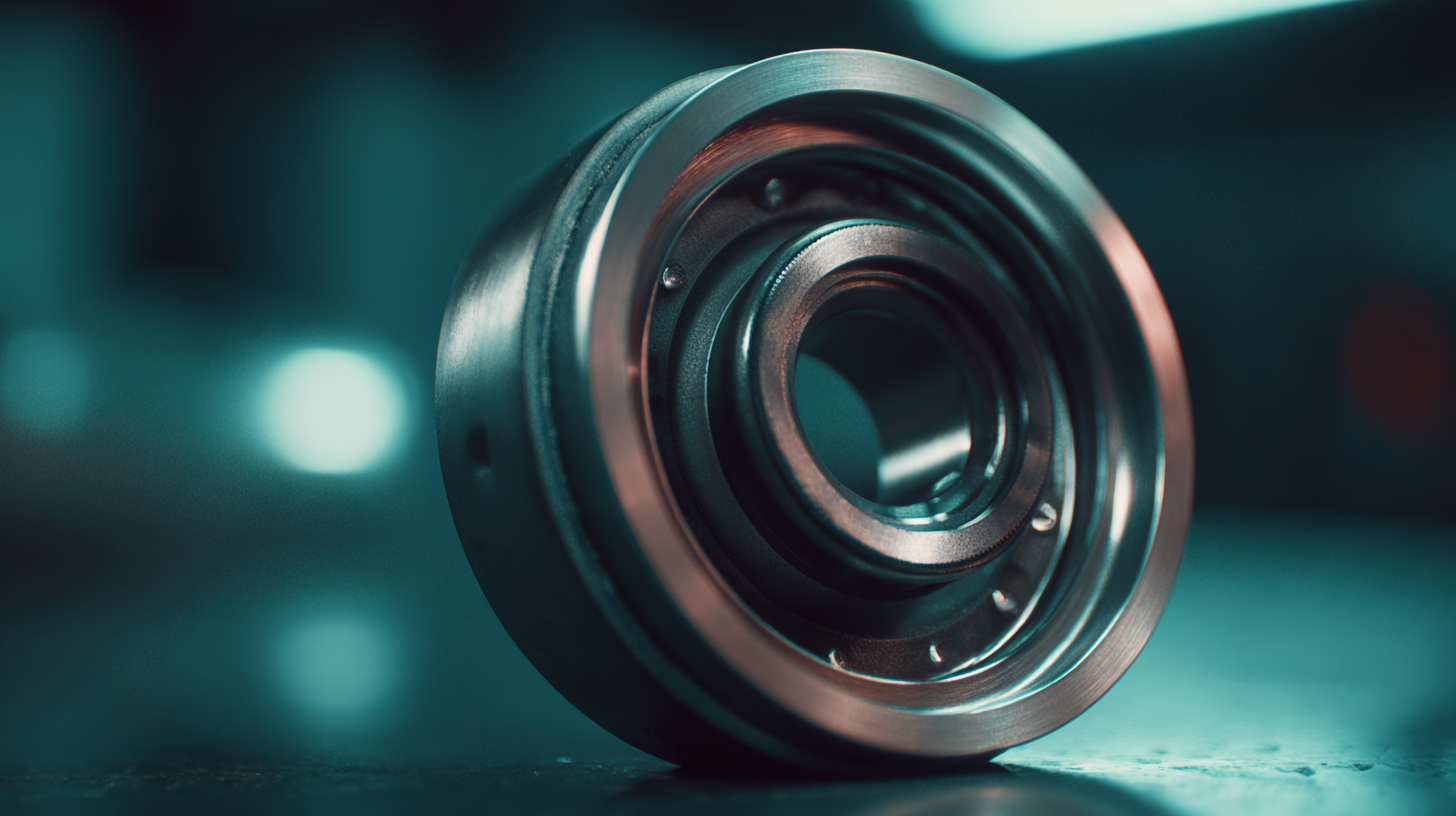

Material Choices for Rear Bearings: Pros and Cons

When selecting rear bearings for production needs, the material choice plays a crucial role in performance and longevity. Common materials for rear bearings include steel, ceramic, and polymers, each presenting distinct advantages and potential drawbacks. Steel bearings are widely favored for their strength and durability, making them suitable for high-load applications. However, they also come with the downside of being susceptible to corrosion without proper lubrication and maintenance.

Ceramic bearings, on the other hand, offer remarkable resistance to wear and temperature fluctuation, which makes them ideal for high-speed applications. They are notably lighter than steel bearings, which can lead to improved efficiency. Nevertheless, the primary drawback of ceramic materials is their higher cost and potential brittleness under severe loads. Meanwhile, polymer bearings are gaining popularity due to their lightweight and corrosion-resistant properties, making them well-suited for applications exposed to moisture or harsh environments. However, they may not handle heavy loads as effectively as their steel or ceramic counterparts. Evaluating these material options is essential for making an informed decision tailored to specific production needs.

7 Essential Tips for Choosing the Right Rear Bearing for Your Production Needs

This chart demonstrates the pros and cons of different materials used in rear bearings, helping you make an informed choice based on performance and durability.

Maintenance Tips for Prolonging the Life of Rear Bearings

Maintaining the longevity of rear bearings is crucial for ensuring smooth operation and minimizing downtime in production environments.

According to a study by the National Center for Manufacturing Sciences, over 30% of machinery failures

are attributed to bearing wear and tear. To extend the life of rear bearings, regular lubrication is essential.

Utilizing the right type of lubricant not only reduces friction but also prevents rust and corrosion. Industry standards

recommend changing the lubricant every 1,000 operational hours or based on the manufacturer's guidelines,

particularly in high-load applications.

Another vital aspect is the monitoring of operating temperatures. The American Society of Mechanical Engineers

indicates that temperature fluctuations can severely impact bearing life. Ideally, rear bearings should operate within a specified

temperature range; exceeding this can lead to premature failure. Implementing temperature sensors

and routine inspections can aid in identifying potential issues before they escalate. Additionally, aligning the bearings

correctly during installation has been shown to reduce stress and improve efficiency, as misalignment can lead to a 30% decrease in bearing service life

according to the Bearing Specialists Association. Regular training and adherence to

maintenance schedules will ensure that production equipment operates at its best, enhancing overall efficiency.