Understanding Deep Bearing: Types, Applications, and Benefits Explained

In recent years, the field of Deep Bearing has emerged as a vital aspect of modern engineering and industrial design. Experts like Dr. Emily Chen, a leading authority on bearing technologies, emphasize the significance of this component: “Deep Bearings are the backbone of equipment efficiency." This assertion reflects the profound impact that deep bearings have on various applications, ensuring smoother operations across multiple industries.

Deep Bearing technology encompasses various types, each tailored to unique requirements ranging from low friction to high load-bearing capacities. Their applications span sectors, including automotive, aerospace, and manufacturing. Industries are increasingly recognizing the advantages of these bearings, such as improved durability and reduced maintenance costs. However, challenges persist. The complexity of choosing the right type of bearing raises questions about optimal performance and longevity.

Understanding the myriad advantages and potential drawbacks of Deep Bearings is crucial. The insights into technology and its applications can guide better decision-making. Each type presents distinct benefits that must be carefully weighed against specific operational needs. As the field evolves, continued exploration and dialogue are essential for leveraging the full potential of Deep Bearings in engineering practices.

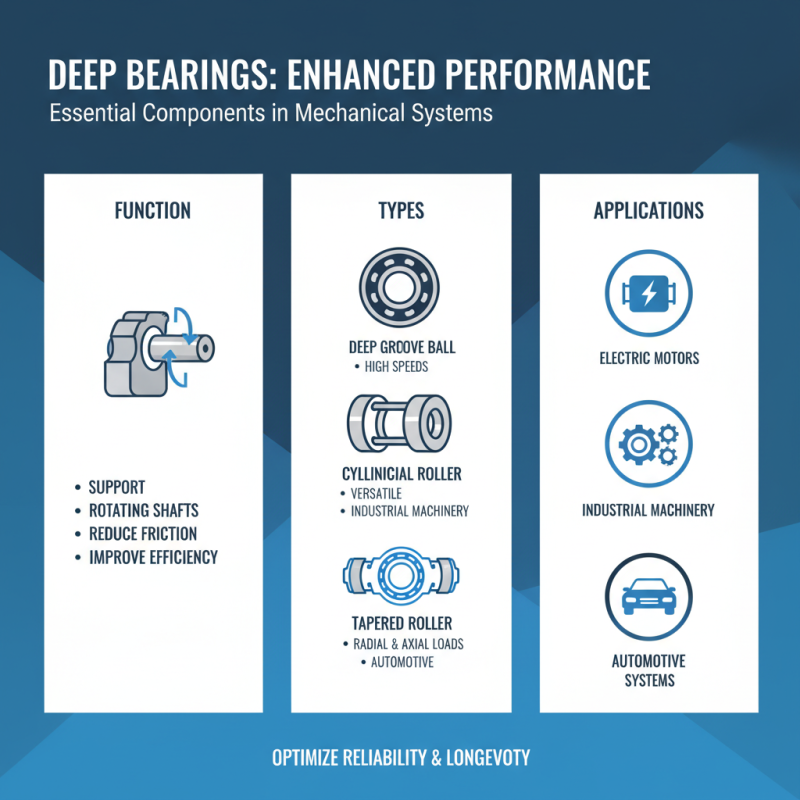

Types of Deep Bearings: An Overview of Key Varieties

Deep bearings are an essential component in various mechanical systems. They support rotating shafts and help reduce friction. Understanding different types of deep bearings can enhance performance in numerous applications. This includes electric motors, industrial machinery, and automotive systems.

There are several key varieties of deep bearings available. Ball bearings are widely used due to their versatility. They can handle both radial and thrust loads efficiently. Another common type is roller bearings, which offer higher load capacities. Their design allows for more contact area, boosting durability. According to a recent report by the Bearings Market Research Institute, global demand for these components is expected to grow by 7.2% annually until 2026.

However, it's essential to choose the right type for specific applications. Overlooking this can lead to mechanical failures. For instance, improper bearing selection leads to increased wear and tear. Engineers need to focus on the required load capacity and speed. Without careful attention, operational costs may increase significantly. This highlights the need for informed decision-making in bearing selection.

Applications of Deep Bearings in Various Industries

Deep bearings play a crucial role in many industries. These components help reduce friction, making machinery more efficient. They are used in automotive, aerospace, and manufacturing sectors. In automotive applications, deep bearings help support rotating parts, ensuring smooth operation. The precision they offer can improve performance, but installation errors can lead to failures.

In the aerospace industry, deep bearings are vital for flight safety. They are used in engines, landing gears, and control systems. Their reliability is paramount. However, intense operational conditions can sometimes lead to wear and tear faster than anticipated. This highlights the importance of regular maintenance.

Manufacturing also relies heavily on deep bearings. They are integral in conveyor systems and pumps. These applications require durability under heavy loads. Any inconsistency in bearing quality can lead to production halts. A thorough understanding of each application's specific needs is essential for success.

Benefits of Utilizing Deep Bearings in Engineering Solutions

Deep bearings are essential components in many engineering applications. They offer several benefits that enhance performance and reliability. According to a report by the National Institute of Standards and Technology, deep bearings can increase load capacity by up to 30%. This advantage makes them ideal for heavy machinery and industrial equipment.

The applications for deep bearings are vast. They are commonly used in automotive, aerospace, and manufacturing sectors. In these industries, the bearing's ability to handle high loads while minimizing friction is crucial. A study by the American Society of Mechanical Engineers highlights that using deep bearings can improve energy efficiency by 15%. This translates to cost savings and reduced environmental impact.

However, the choice of bearing must be considered carefully. Not all applications benefit from deep bearings. In some cases, they may complicate assembly processes or increase material costs. Industries must weigh these factors against the performance benefits. The application of deep bearings should align with specific engineering requirements. This alignment ensures optimal performance while addressing potential drawbacks.

Understanding the Benefits of Deep Bearings in Engineering Solutions

Maintenance and Care for Deep Bearings: Best Practices

Deep bearings play a crucial role in various industrial applications. Their efficiency is directly linked to proper maintenance. Neglect can lead to premature failure. Industry reports indicate that improper maintenance can increase operational costs by up to 30%. Regular inspection is essential. Check for signs of wear, lubrication levels, and alignment issues.

Applying the right lubrication is vital. Many experts recommend using specific greases based on operating conditions. Not all lubricants are suitable for every bearing type. In fact, mismatched lubricants can lead to overheating and increased friction. Deep bearings should be re-lubricated according to the manufacturer’s guidelines. This often involves intervals of every few months, depending on usage.

Cleaning is another key aspect. Dust and debris can accumulate, compromising performance. Cleaning should be systematic and thorough. Yet, many overlook this step. A lack of diligent cleaning can result in significant downtime. Monitoring vibration levels is also valuable. Sudden spikes can signal an underlying issue. Adopting these best practices can enhance the longevity of deep bearings.

Future Trends in Deep Bearing Technology and Development

The future of deep bearing technology holds immense potential. As industries evolve, the demand for reliable components increases. Manufacturers are exploring new materials. These materials promise enhanced strength and durability. Innovations in design also play a crucial role. Advanced modeling techniques help engineers create optimized shapes. This reduces stress points and enhances performance.

Another exciting trend is the integration of smart sensors. These sensors can monitor real-time conditions. They provide valuable data on wear and tear. This allows for predictive maintenance, minimizing unexpected failures. However, implementing such technology is not without challenges. Engineers must address the complexity of data management. Additionally, the cost of these technologies can be high. Companies need to weigh benefits against investments.

Sustainability is also becoming essential. Eco-friendly materials are gaining traction in deep bearing production. The manufacture of components that reduce energy consumption is vital. Yet, transitioning to sustainable methods requires deep reflection. Many firms struggle with balancing innovation and environmental responsibility. As the industry progresses, these reflections will help shape future developments.

Related Posts

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

The 5 Best Abs Bearings for Ultimate Performance and Durability in 2023

-

10 Facts About Real Bearing for Optimal Performance in Your Machinery

-

Forecasting the Brake Bearings Market Growth Amidst the 138th China Import and Export Fair in 2025

-

What is Tapped Bearing and How Does It Enhance Mechanical Performance

-

Top 10 Deep Bearing Types for Optimal Performance in Various Applications