Top Tips for Choosing Truck Bearings to Enhance Performance and Longevity

In the robust world of trucking, the reliability of a vehicle often hinges on the quality of its parts, and truck bearings stand out as a critical component influencing both performance and longevity. According to John Smith, a leading expert in the truck bearings industry, “Choosing the right bearings can mean the difference between seamless operation and costly downtimes.” With the heavy loads and demanding conditions that trucks face daily, the significance of selecting appropriate truck bearings cannot be overstated.

When optimizing for performance, truck bearings play a vital role in reducing friction, ensuring smooth rotation, and ultimately extending the lifespan of the entire vehicle. The process of choosing the right bearings can be complex, but understanding key factors such as load capacity, material compatibility, and environmental conditions can lead to informed decisions. By prioritizing the right specifications, truck owners can enhance operational efficiency and minimize maintenance costs.

As we delve into the top tips for selecting truck bearings, it’s imperative to highlight not just the technical aspects, but also how these choices contribute to a truck’s overall reliability and operational success. In an industry where every detail matters, ensuring the right bearing choice can be a game changer.

Key Factors to Consider When Selecting Truck Bearings for Optimal Performance

When selecting truck bearings, several key factors play a crucial role in ensuring optimal performance and longevity. First and foremost, it is essential to consider the load capacity of the bearings. According to industry reports from the American Bearing Manufacturers Association (ABMA), bearings should be rated to withstand not only the dynamic loads encountered during operation but also the static loads when the truck is stationary. Underestimating load requirements can lead to premature failure and costly downtime. An appropriate safety factor, typically 1.5 to 2 times the expected load, is often recommended for prolonged bearing life.

Another significant factor is the type of lubrication used. Studies show that the choice of lubricant can impact bearing performance by as much as 50%. Grease lubricated bearings, for example, can provide better protection against contamination, while oil lubrication may be more suitable for high-speed applications. The National Lubricating Grease Institute (NLGI) offers guidelines on selecting lubricants based on operational conditions and bearing types, emphasizing the importance of matching the lubricant to the operating environment to maximize efficiency and lifespan.

Lastly, environmental conditions must not be overlooked. Exposure to extreme temperatures, moisture, or contaminants can severely affect bearing integrity. The International Organization for Standardization (ISO) recommends selecting bearings that meet specific environmental ratings to ensure reliability in diverse conditions. By taking these factors into account, operators can enhance the performance and longevity of truck bearings, ultimately leading to improved vehicle reliability and reduced maintenance costs.

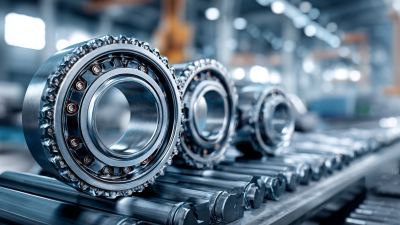

The Role of Bearing Materials in Enhancing Truck Durability and Efficiency

When it comes to enhancing the durability and efficiency of trucks, the choice of bearing materials plays a pivotal role. A report by the National Institute for Automotive Service Excellence indicates that approximately 40% of mechanical failures in trucks can be traced back to inadequate bearing materials. Selecting the right bearing material not only improves the lifespan of the components but also optimizes performance under varying loads and conditions. For instance, high-quality steel bearings offer superior load-bearing capabilities, while advanced composite materials can enhance resistance to fatigue and corrosion, critical for long-haul applications.

Moreover, recent studies by the Society of Automotive Engineers have shown that trucks equipped with bearings made from advanced polymer composites exhibit a reduction in weight by up to 30%. This weight reduction can translate into improved fuel efficiency, as lighter trucks require less energy to operate. Furthermore, these modern materials often provide better thermal management, enabling the bearings to perform under extreme conditions without significant wear. As the industry continues to evolve, the integration of cutting-edge materials in bearing design is essential for maximizing the efficiency and longevity of trucks, contributing to overall operational cost savings for fleet operators.

Understanding Load Ratings and Their Impact on Bearing Longevity in Trucks

When selecting bearings for trucks, understanding load ratings is crucial for optimizing performance and ensuring longevity. Load ratings are indicators of the bearing's capacity to withstand forces while maintaining its structural integrity. According to the American National Standards Institute (ANSI) standards, proper load rating selection is vital; exceeding the load operating specifications can lead to premature bearing failure, costing companies significant downtime and repair expenses. For instance, improperly rated bearings can experience fatigue failure within 500 hours of operation when subjected to loads beyond their specified ratings, as reported by the Bearing Specialists Association (BSA).

Moreover, the interaction between load ratings and bearing longevity is a critical factor in maximizing vehicle performance. Research from the International Journal of Heavy Vehicle Systems highlights that bearings engineered with optimal load ratings can operate efficiently for over 10,000 hours under standard conditions. This longevity is attributed to reduced wear and tear, which is further enhanced by regular maintenance and proper lubrication. Therefore, truck operators must prioritize the selection of bearings that not only support the necessary load but also fit the specific operational environment, ensuring reliability and extending the lifespan of their fleet.

Maintenance Practices That Extend the Life of Truck Bearings

Proper maintenance of truck bearings is crucial for enhancing their performance and extending their lifespan. Regular inspections are the first step in a robust maintenance routine. Technicians should check for signs of wear, such as noise, vibration, or overheating. Early detection of these issues can prevent more significant damage and costly repairs. Additionally, keeping bearings clean and free from contaminants is essential, as dirt and debris can lead to premature failure. Using appropriate sealing methods can help protect bearings from the harsh environments they often operate in, ensuring they function optimally.

Lubrication also plays a vital role in the longevity of truck bearings. Utilizing the right type of lubricant and applying it at the correct intervals helps reduce friction and wear, promoting smoother operation. Operators should follow manufacturer recommendations regarding lubricant specifications and application techniques to maximize effectiveness. Furthermore, monitoring lubrication levels regularly can prevent issues associated with either over- or under-lubrication. By implementing these maintenance practices, truck operators can ensure their bearings remain in peak condition, ultimately enhancing vehicle performance and reliability.

Top Tips for Choosing Truck Bearings to Enhance Performance and Longevity

| Tip Number | Tip Description | Recommended Maintenance Frequency | Expected Lifespan (Months) |

|---|---|---|---|

| 1 | Choose the Right Bearing Type for Your Application | Every 6 months | 24 |

| 2 | Regular Lubrication to Reduce Friction | Monthly | 18 |

| 3 | Inspect Bearing Alignment Regularly | Every 3 months | 30 |

| 4 | Monitor Temperature and Vibration Levels | Continuous Monitoring | 36 |

| 5 | Replace Worn-Out Bearings Promptly | As needed | Varies |

Industry Standards and Innovations in Truck Bearing Technology

In the rapidly evolving world of truck bearing technology, adhering to industry standards while embracing innovations is crucial for optimal performance and longevity. The latest reports indicate that advanced materials and design enhancements have significantly improved the durability of truck bearings. According to a 2023 industry evaluation by the National Lubricating Grease Institute, bearings made with high-performance polymers and smart materials can increase the lifespan by up to 30%, translating to reduced maintenance costs and improved safety.

When choosing truck bearings, it is essential to prioritize compatibility with established industry standards such as ISO 281, which outlines the basic rating life of rolling bearings. This ensures not only quality and reliability but also helps in extending service intervals. Moreover, recent innovations like real-time monitoring systems are becoming more prevalent, enabling fleet managers to assess the condition of bearings proactively. Implementing these technologies can lead to preventive maintenance, reducing unexpected breakdowns.

Tip: Always consider the load capacity and speed rating of bearings to ensure they match your truck's specifications. Overloading bearings can lead to premature failure, while selecting bearings that support higher speeds can enhance fuel efficiency. Another tip is to consult with engineering assessments to analyze the operating environment of your fleet—this insight can guide decisions on materials and protective coatings, thus significantly improving the overall performance and lifespan of truck bearings.

Related Posts

-

10 Best Truck Bearings for Optimal Performance and Durability

-

How to Optimize Your Projects with Tape Bearing Solutions

-

Exploring the Future of Power Bearings Innovations and Applications in Modern Machinery

-

Exploring Opportunities for Auto Bearings at the 138th Canton Fair 2025: Industry Trends and Insights

-

The Ultimate Guide to Choosing the Best Bearing Needles in 2025

-

2025 How to Choose the Best Tire Bearings for Optimal Vehicle Performance