How to Choose the Right Real Bearing for Your Needs?

Choosing the right Real Bearing is crucial for optimal performance in machinery and equipment. As industry expert John Carter says, "Selecting the correct bearing can make all the difference in efficiency and longevity." When you consider various types of Real Bearings, factors like load capacity, speed, and environmental conditions come into play.

Each application demands specific features. You'll find yourself pondering the right materials, design, and size. For instance, a high-speed application might require ceramic bearings, while heavy-duty tasks may need steel options. It’s easy to overlook the need for proper lubrication and installation techniques too. These details can be the difference between success and failure.

Understanding the balance between cost and quality is also vital. Some might lean towards cheaper options, but this can lead to regrets down the line. Achieving the right fit for your needs involves thoughtful research and examination. Mistakes here can compromise efficiency or even lead to machine downtime. So, dive deep into your choices with an open mind and a pragmatic approach.

Understanding Different Types of Real Bearings Available in the Market

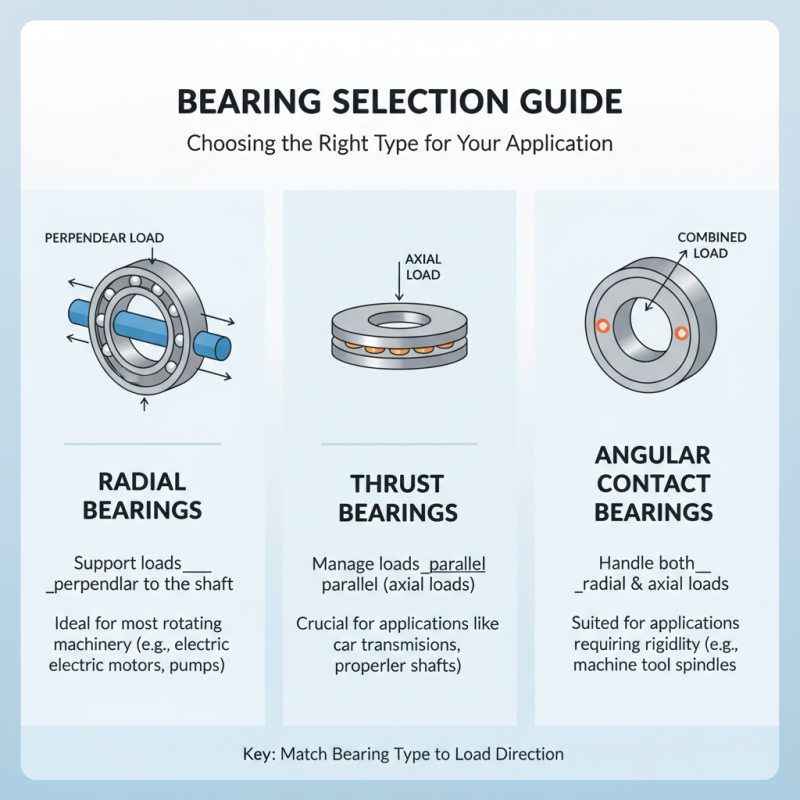

When selecting the right real bearing, it’s essential to understand the various types available. There are several categories, including radial bearings, thrust bearings, and angular contact bearings. Each type serves a specific purpose and is suited to different applications. Radial bearings support loads perpendicular to the shaft, making them ideal for most rotating machinery. Thrust bearings, on the other hand, manage axial loads, which is crucial for applications like car transmissions.

Another significant category is the angular contact bearing. It operates at an angle and is designed for combined loads, making it versatile for many industrial uses. However, many users overlook the differences between these types. Choosing the wrong one can lead to poor performance. Inadequate load capacity might result in rapid wear and tear. It's crucial to examine your requirements carefully.

Don't forget about material choices. Bearings are commonly made from steel, ceramic, or plastic. Each material has its benefits and drawbacks. For instance, ceramic bearings can resist corrosion but may be less durable under heavy loads. Reflecting on your specific needs can help avoid costly mistakes.

Identifying Your Specific Application Requirements for Real Bearings

When selecting the right real bearings, understanding your specific application requirements is crucial. The type of load, speed, and environmental conditions will significantly influence your choice. For instance, a report from the International Bearing Industry Association noted that over 70% of bearing failures stem from incorrect specifications. This staggering figure underscores the importance of meticulous selection.

Consider temperature ranges. Certain bearings withstand high heat better than others. Those used in motors may require bearings with better heat resistance. Conversely, if the application involves exposure to moisture, a rust-resistant option is vital. A study indicates that moisture exposure can reduce bearing lifespan by 30% if not properly accounted for.

Noise levels also matter. Applications in sensitive environments need quieter bearings. Some reports highlighted that noisy bearings can lead to operational disruptions, costing industries millions. Evaluating these aspects can feel overwhelming. Overanalyzing may delay your decision.

Prioritize clear requirements and consult industry standards. Ultimately, a thoughtful approach can lead to improved performance and longevity of your machinery.

Evaluating the Key Material Options for Real Bearings

When choosing the right bearings, material options carry significant weight. Steel and ceramic are two primary materials to consider. According to industry reports, steel bearings dominate with over 60% market share. They are tough and widely used in various applications. However, they can rust and wear down quickly in harsh environments.

Ceramic bearings, while less common, have unique advantages. They resist corrosion and have lighter weights. Reports indicate that they can last five times longer than steel in certain conditions. However, they can be brittle and expensive.

It's crucial to evaluate your specific needs. Environment, load capacity, and operational speed all matter. Problems often arise when materials are mismatched to applications. Understanding the strengths and weaknesses of each option aids in making informed choices. Each bearing material has trade-offs. It’s vital to reflect on these nuances before deciding.

Assessing Load Capacity and Performance Ratings for Real Bearings

When selecting a real bearing, understanding load capacity is vital. Load capacity refers to the maximum weight a bearing can support without failure. Numerous studies suggest that a bearing should handle at least 20-25% more than the expected load to ensure safety. For instance, bearings used in automotive applications often need to meet a static load rating of around 20,000 N to perform effectively under typical conditions.

Performance ratings also play a crucial role in bearing selection. These ratings assess factors like speed capabilities and operating temperature. According to industry reports, the operating temperature of bearings should typically not exceed 120°C for optimal performance. High-speed bearings may require special materials and lubrication to maintain functionality. It's essential to remember that not all bearings perform equally under stress.

Many users overlook these specifications and later face unexpected failures. For example, frequent underestimation of load requirements can lead to premature bearing wear. Additionally, selecting a bearing without evaluating its thermal limits could result in operational disruptions. Evaluating these factors is crucial for ensuring the longevity of your machinery and maintaining efficiency in industrial applications.

Load Capacity and Performance Ratings for Real Bearings

Considering Environmental Factors Affecting Real Bearing Selection

When selecting real bearings, environmental factors play a crucial role. Temperature, humidity, and exposure to chemicals can impact the bearing's performance and life span. For instance, bearings operating in damp conditions may require special seals to prevent moisture ingress. Research shows that bearings can fail 30% faster in environments with high humidity without proper protection.

The lubrication used also matters significantly. In harsh conditions, conventional lubricants may break down more quickly. This can lead to increased wear and potential failure. Industry data indicates that over 40% of bearing failures are due to inadequate lubrication in extreme conditions. Therefore, selecting the right grease or oil is essential.

Consider the specifics of the operating environment. High temperatures can change the viscosity of lubricants. Dust and dirt can cause abrasions. Even vibrations can lead to misalignment. Each of these factors should inform your choice. It's important to assess not only the immediate conditions but also how they might change over time. Understanding these nuances can enhance the longevity and reliability of your bearings.

How to Choose the Right Real Bearing for Your Needs? - Considering Environmental Factors Affecting Real Bearing Selection

| Bearing Type | Load Capacity (kg) | Operating Temperature Range (°C) | Speed Rating (RPM) | Environmental Considerations |

|---|---|---|---|---|

| Deep Groove Ball Bearing | 1000 | -20 to 120 | 5000 | Low Noise, Moderate Dust Exposure |

| Angular Contact Bearing | 800 | -30 to 150 | 6000 | High Precision, Low Lubrication |

| Thrust Ball Bearing | 500 | -10 to 100 | 3000 | Moderate Pressure, Vibration Resistance |

| Roller Bearing | 1300 | -20 to 100 | 4000 | High Load, Environmental Protection Required |

Related Posts

-

The 5 Best Abs Bearings for Ultimate Performance and Durability in 2023

-

How to Choose the Perfect Real Bearing for Your Industrial Applications

-

10 Facts About Real Bearing for Optimal Performance in Your Machinery

-

Understanding Deep Bearing: Types, Applications, and Benefits Explained

-

Exploring the Future of Power Bearings Innovations and Applications in Modern Machinery

-

What is a Car Bearing and How Does it Impact Vehicle Performance