How to Choose the Right Ball Bearing for Your Project?

Choosing the right ball bearing for a project involves critical decisions. In the manufacturing industry, ball bearings play a vital role in ensuring operational efficiency and reducing friction. A report from the International Bearing Industry Association indicates that the global ball bearing market is expected to reach $88 billion by 2026.

Expert John Smith, a leading figure in the ball bearing industry, states, "Selecting the appropriate ball bearing can significantly enhance equipment performance." This highlights the importance of precise selection. Not all ball bearings are created equal. Factors such as load capacity, material, and environmental conditions should be carefully assessed.

It's worth noting that many companies overlook these factors. They may choose a ball bearing based on cost alone. This can lead to premature failure and increased maintenance costs. Understanding the specific needs of your application can prevent costly mistakes. Each project has unique requirements, and a short-sighted approach may hinder long-term success.

Understanding the Basics of Ball Bearings and Their Types

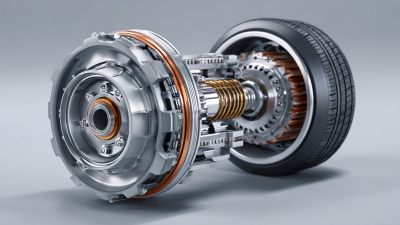

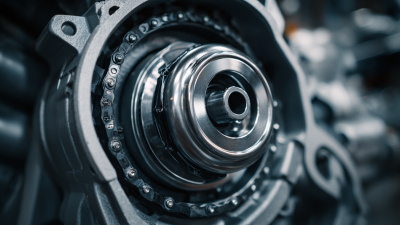

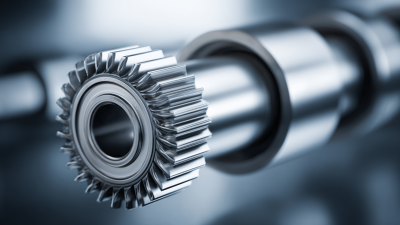

Ball bearings play a critical role in modern machinery. They reduce friction between moving parts, increasing efficiency. Understanding the different types of ball bearings is essential. There are several common categories: deep groove, angular contact, and self-aligning bearings. Each serves unique applications based on load and speed requirements.

Deep groove ball bearings are versatile. They can handle both radial and axial loads. According to industry reports, over 50% of bearings used in motors are deep groove types. Angular contact bearings excel in high-speed applications. They support axial loads better. Self-aligning bearings can compensate for shaft misalignment.

Tips: When selecting bearings, consider load ratings. Higher load ratings often mean better durability. Be mindful of the environment too. Different materials resist corrosion and temperature better. Look for specifications that match your project needs. Remember, the correct choice can significantly impact performance and longevity. Always test your choices. Trial and error can lead to the best outcomes.

How to Choose the Right Ball Bearing for Your Project?

| Bearing Type | Load Capacity (lbs) | Speed Rating (RPM) | Material | Typical Applications |

|---|---|---|---|---|

| Deep Groove Ball Bearing | 200 | 15,000 | Steel | Electric Motors, Household Appliances |

| Angular Contact Ball Bearing | 350 | 20,000 | Stainless Steel | Spindles, Pumps |

| Self-Aligning Ball Bearing | 250 | 10,000 | Chrome Steel | Agricultural Equipment, Conveyors |

| Thrust Ball Bearing | 150 | 8,000 | Carbon Steel | Machine Tools, Automotive |

| Ceramic Ball Bearing | 450 | 30,000 | Ceramic | High-Speed Applications, Aerospace |

Key Factors to Consider When Choosing Ball Bearings

Choosing the right ball bearing can be tricky. You need to consider several key factors. First, think about the load requirements. Will your project face heavy loads or light ones? Different bearings handle different levels of stress. A mismatched choice can lead to early failure.

Next, consider the environmental conditions. Is it damp or dusty where the bearing will be used? Materials like stainless steel are often preferred for corrosive environments. But remember, they can be more expensive. Continuous exposure could still wear them down.

Another factor is lubrication. Some bearings come pre-lubricated. Others require regular maintenance. If you're unsure about upkeep, choose bearings that are easier to maintain. Don't overlook the size and fit either. An ill-fitting bearing can cause friction. This is often a reflection of unclear measurements or mismatched specifications. Each of these factors plays a crucial role in overall performance.

Assessing Load Requirements and Operating Conditions

Choosing the right ball bearing starts with understanding load requirements. Different applications demand different load capacities. For example, a small hobby project may require lightweight bearings. A heavy industrial machine, however, needs robust bearings to support larger weights. Misjudging the load can lead to premature failure.

Next, consider the operating conditions. Factors like temperature, humidity, and exposure to contaminants are crucial. High temperatures can degrade certain materials. Likewise, moisture can lead to corrosion. Ensure the bearings can withstand their environment. Sometimes, it’s hard to anticipate all conditions. That’s where testing comes into play.

Balancing load and conditions is a challenge. The selection process can feel overwhelming. Some projects require versatility, while others call for specialized bearings. Keep in mind; it’s not just about the initial choice. Regular maintenance plays a significant role too. Reviewing performance can lead to better decisions in the future.

Evaluating Material Choices for Durability and Performance

When selecting the right ball bearing for your project, material choice is crucial. Different materials impact durability and performance significantly. Steel is a common choice due to its strength and cost-effectiveness. However, it may corrode over time, especially in damp environments. Consider stainless steel for better resistance to rust and wear, but it can be pricier.

Ceramic bearings offer unique advantages. They are lighter and can withstand higher temperatures. Their smooth surface reduces friction, enhancing overall efficiency. Yet, they may not be suitable for heavy loads. Evaluating your project's specific needs can help decide between these materials.

Sometimes, you might feel overwhelmed with choices. Testing various materials can provide insights into their real-world performance. Keep an eye on their behavior under stress. Recognizing the limitations of each material is key to making an informed decision. This process can be frustrating but is essential for achieving optimal results.

Comparing Cost and Availability of Ball Bearing Options

When selecting ball bearings for your project, cost and availability should be top priorities. There are various types of ball bearings. Each type has a different price point. Some options are more readily available than others. Researching local suppliers is a good start. Online marketplaces also provide many options. However, prices can vary significantly between platforms.

Consider the materials used in the bearings. Stainless steel tends to be more durable but may carry a higher price. Plastic bearings can be a budget-friendly option but may not last as long. Keep in mind your project's demands. If you're working on something that requires high precision, investing more might be necessary.

**Tips:** Always compare prices from different sources. Don’t rush into a purchase. Take your time to verify reviews. Sometimes, a lower price means lower quality. Check the lead times for availability. Delays can affect your project timeline. If in doubt, ask for samples before committing.

Comparison of Ball Bearing Types Based on Cost and Availability

Related Posts

-

Unlocking Performance: The Essential Role of Tire Bearings in Modern Vehicle Dynamics

-

Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

-

2025 How to Choose the Best Tire Bearings for Optimal Vehicle Performance

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Auto Bearing for Your Vehicle

-

Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

-

10 Best Truck Bearings for Optimal Performance and Durability