How to Choose the Perfect Real Bearing for Your Industrial Applications

In the ever-evolving landscape of industrial applications, selecting the right components is crucial for optimizing performance and efficiency. Among these components, the importance of choosing the perfect real bearing cannot be overstated. According to a report by MarketsandMarkets, the global bearing market is projected to reach $105.5 billion by 2025, driven by increasing demand for advanced machinery across various sectors. Real bearings play a pivotal role in enhancing the reliability and longevity of equipment, reducing friction and wear, and ultimately leading to significant cost savings. However, with a multitude of options available, navigating the selection process can be daunting. This blog aims to provide insights into the key factors to consider when choosing real bearings for your industrial needs, ensuring you make informed decisions that align with your operational goals.

Understanding the Importance of Bearing Types in Industrial Applications

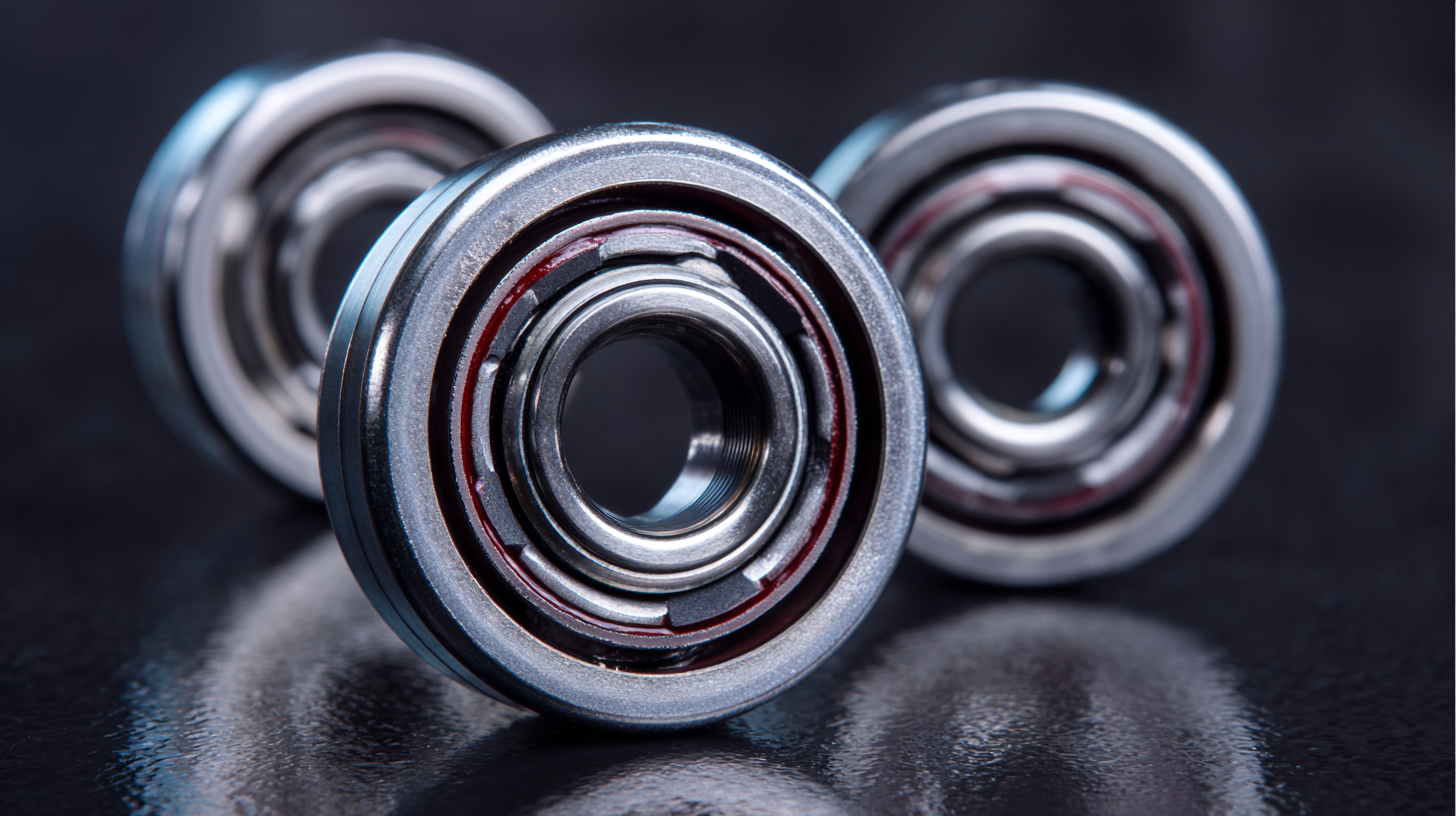

When it comes to industrial applications, the choice of bearing type is crucial for ensuring optimal performance and longevity of machinery. Bearings are designed to support loads, manage friction, and enable smooth rotation or movement of parts. Understanding the various bearing types available—such as ball bearings, roller bearings, and thrust bearings—can significantly impact the efficiency and reliability of equipment. Each bearing type has its unique characteristics that suit different operational demands, whether it’s high-speed machinery or heavy-load applications.

The importance of selecting the right bearing extends beyond mere functionality; it also affects maintenance schedules and overall operational costs. For instance, while ball bearings are adept at handling moderate loads at high speeds, roller bearings are better suited for heavy loads due to their larger surface area. Furthermore, considerations such as environmental conditions, lubrication needs, and load direction play vital roles in determining the appropriate bearing type. By comprehensively understanding these factors, industries can prevent premature wear, minimize downtime, and ultimately enhance productivity.

How to Choose the Perfect Real Bearing for Your Industrial Applications - Understanding the Importance of Bearing Types in Industrial Applications

| Bearing Type | Load Capacity (kN) | Speed (RPM) | Temperature Range (°C) | Application Examples |

|---|---|---|---|---|

| Radial Ball Bearing | 10 - 100 | 1000 - 12000 | -20 to 80 | Electric motors, pumps |

| Tapered Roller Bearing | 20 - 300 | 500 - 3000 | -20 to 120 | Trucks, gearboxes |

| Spherical Roller Bearing | 30 - 400 | 300 - 1500 | -20 to 100 | Conveyor systems, construction machinery |

| Angular Contact Bearing | 15 - 250 | 1000 - 8000 | -30 to 120 | Machine tools, high-speed applications |

| Deep Groove Ball Bearing | 5 - 80 | 500 - 18000 | -20 to 125 | Electrical devices, fans |

Key Factors in Selecting the Right Bearing: Load, Speed, and Environment

When selecting the perfect real bearing for industrial applications, it's essential to consider key factors such as load, speed, and environment. Load capacity is a primary concern; according to a recent report by the International bearing industry Association (IBIA), approximately 70% of bearing failures are attributed to excessive load conditions. To ensure longevity and performance, it is crucial to match the bearing's load rating with peak service requirements, particularly for high-demand environments.

Speed is another pivotal factor, as many bearings are designed specifically for optimal performance at certain RPM thresholds. The American Society of Mechanical Engineers (ASME) indicates that increasing operating speeds beyond specified limits can lead to overheating and premature fatigue. For instance, bearings used in high-speed applications, such as turbines or electric motors, typically require materials that can withstand elevated temperatures and reduced lubrication adequacy.

Lastly, understanding the operating environment is vital in bearing selection. Environmental factors such as temperature, humidity, and exposure to contaminants can drastically affect bearing performance. The Machinery Lubrication magazine emphasizes that bearings used in harsh conditions, like those found in mining or food processing, must be designed to resist corrosion and wear. Choosing the right materials and seals can significantly enhance reliability and minimize downtime in these challenging settings.

Analyzing Materials: The Best Choices for Durability and Performance

When selecting the perfect real bearing for industrial applications, analyzing the materials is crucial for ensuring both durability and performance. A recent report from the International Journal of Advanced Manufacturing Technology reveals that over 40% of bearing failures can be attributed to material selection and processing inadequacies. For high-load applications, materials like bearing steel and ceramic composites demonstrate superior wear resistance, with ceramic bearings lasting up to five times longer than their steel counterparts under optimal conditions.

In terms of specific material characteristics, stainless steel bearings provide excellent corrosion resistance, making them ideal for industries exposed to harsh environments, such as food processing or chemical manufacturing. According to a study from the American Society of Mechanical Engineers (ASME), stainless steel bearings exhibit a 70% lower failure rate in corrosive settings compared to traditional carbon steel options. Additionally, the use of nylon and polymer bearings offers lightweight and cost-effective alternatives for low-load applications, where they can outperform metal bearings in terms of friction and noise reduction, ultimately leading to increased operational efficiency.

Industry Trends: Innovations in Bearing Technology for Enhanced Efficiency

In today's rapidly evolving industrial landscape, bearing technology is at the forefront of driving efficiency and performance. Recent innovations have introduced advanced materials and designs that reduce friction and wear, leading to longer service life and minimal downtime. For instance, ceramic-bearing composites are becoming increasingly popular due to their lightweight properties and resistance to extreme temperatures, making them ideal for high-speed applications.

Moreover, the rise of smart technology in bearings is revolutionizing maintenance practices. IoT-enabled bearings equipped with sensors allow for real-time monitoring of performance metrics such as temperature, vibration, and load. This data-driven approach enables predictive maintenance, reducing unexpected failures and optimizing overall equipment lifecycle. As industries strive for higher productivity and lower operational costs, these technological advancements in bearing design and monitoring are set to play a crucial role in enhancing efficiency.

Trends in Bearing Technology Efficiency

Cost vs. Quality: Striking the Balance for Optimal Bearing Selection

Choosing the right bearings for industrial applications is a critical decision that balances cost and quality. While it might be tempting to opt for the cheapest options available, doing so can lead to long-term issues such as increased maintenance costs and decreased equipment efficiency. High-quality bearings often incorporate advanced materials and precise engineering, ensuring longevity and reliability. Investing in these products may mean higher upfront costs, but the resultant reduction in downtime and enhanced performance can lead to significant savings over time.

On the other hand, a focus solely on quality without considering budget constraints can strain operational costs. A pragmatic approach involves evaluating the performance requirements of the specific application. This includes factors such as load capacity, speed, and environmental conditions. By aligning bearing selections with both performance needs and budget limitations, industries can achieve a balanced solution. In many cases, understanding the total cost of ownership — as opposed to the initial purchase price — provides valuable insight into the true value of bearings in industrial settings. Finding this equilibrium is essential for optimizing operational efficiency while maintaining fiscal responsibility.

Related Posts

-

Understanding the Functionality and Benefits of Nup Bearing Types

-

7 Essential Tips for Choosing the Right Rear Bearing for Your Production Needs

-

How to Choose the Right Pillow Bearing for Your Industrial Applications

-

10 Essential Tips for Choosing the Perfect Tapped Bearing

-

7 Essential Tips for Choosing the Best Pillar Bearing for Your Needs