2026 How to Choose the Right Needle Bearings for Your Projects?

Choosing the right needle bearings for your projects can significantly impact performance. Needle bearings are essential in various applications, from automotive to industrial machinery. Industry reports indicate that the needle bearing market is projected to grow by 7.2% annually through 2026. This growth underscores their importance in improving efficiency and reducing friction.

When selecting needle bearings, it is vital to consider load capacity, speed, and operating environment. The right choice can enhance mechanical effectiveness. Research shows that up to 30% of mechanical failures are due to bearing selection failures. This highlights the need for careful evaluation. Additionally, improper bearings may lead to unplanned downtimes, incurring hefty costs.

It’s also crucial to recognize that not all needle bearings are created equal. Variations in materials and design can lead to significant differences in performance. Reflecting on these factors could prevent potential setbacks in your projects. Thus, thorough research and understanding are necessary for optimal bearings selection.

Understanding Needle Bearings: Types and Applications

Needle bearings are crucial in various applications. They are known for their ability to handle high load capacities in small spaces. Their design includes thin cylindrical rollers, which reduce friction and improve performance. Reports indicate that the global needle bearing market is projected to grow by 5.2% annually from 2022 to 2028. This is driven by the increasing demand in automotive and industrial sectors.

Different types of needle bearings exist, each suited for specific functions. For example, drawn cup needle bearings are ideal for tight spaces. They offer excellent load capacity and low friction. On the other hand, caged needle bearings provide stability and are used where axial and radial loads occur simultaneously. According to industry data, applications in electric motors and gear systems significantly drive needle bearing usage. However, poor alignment in installation can lead to premature failure, a point often overlooked.

Choosing the right type involves understanding specific project needs. Consider load conditions, speed requirements, and environmental factors. For instance, high-speed applications demand needle bearings with minimal heat generation. Yet, frequently, engineers may underestimate the importance of lubrication. Proper lubricants significantly extend the lifespan of these bearings. This highlights a common oversight that could impact project outcomes.

Key Factors to Consider When Selecting Needle Bearings

When selecting needle bearings for your projects, there are key factors to consider.

Size is important. The bearing's inner and outer diameters must fit your components.

Check the shaft size and housing to ensure compatibility. Also, the load capacity matters. Different applications demand different strengths.

Weigh the loads you expect against the bearing specifications.

Material choice is another critical aspect. Needle bearings can be made from various materials. Steel is common, but alternatives exist.

Consider the working environment. Will there be moisture? If so, using corrosion-resistant materials may be wise.

Another factor is lubrication. Some needle bearings come pre-lubricated, while others do not. The lubrication method affects performance and lifespan.

Evaluate your project’s specific needs. Installation can be tricky. Ensure you have the right tools and expertise to avoid mistakes.

Incorrect installation can lead to premature failure. Lastly, always reflect on your decision process. Did you fully assess all variables?

Remember, the right bearing makes a significant difference in your project’s success.

Assessing Load Capacity and Performance Requirements

Choosing the right needle bearings for your project is essential. Load capacity and performance requirements are critical factors. Each application demands specific characteristics from the needle bearings. For instance, a report by the International Journal of Mechanical Engineering indicated that over 30% of bearing failures stem from improper load assessments.

Understanding load capacity is vital. A bearing with a higher load capacity can handle more weight, reducing the risk of failure. In applications with fluctuating loads, opt for bearings designed to withstand dynamic forces. Research shows that using bearings exceeding load requirements can increase durability. However, there is a fine line. Overloading can lead to premature failure, an issue many engineers overlook.

Performance requirements also play a significant role. Friction and heat generation are critical metrics. A study highlighted that bearings operating at high speeds should have low friction coefficients to ensure efficiency. Some projects may face unexpected loads. This unpredictability can lead to performance issues. Regular assessments should be part of maintenance protocols, ensuring that bearings meet evolving project needs. Factors like environmental conditions and lubrication regimes must be considered. Balancing all these aspects is challenging and requires continuous evaluation.

2026 How to Choose the Right Needle Bearings for Your Projects? - Assessing Load Capacity and Performance Requirements

| Needle Bearing Type | Inner Diameter (mm) | Outer Diameter (mm) | Length (mm) | Dynamic Load Capacity (kN) | Static Load Capacity (kN) | Speed Rating (rpm) |

|---|---|---|---|---|---|---|

| Standard Needle Bearing | 10 | 19 | 20 | 16.5 | 24.0 | 13000 |

| Heavy Duty Needle Bearing | 15 | 30 | 25 | 25.0 | 35.0 | 10000 |

| Stainless Steel Needle Bearing | 12 | 22 | 18 | 18.0 | 26.0 | 12000 |

| Plastic Needle Bearing | 8 | 16 | 15 | 10.0 | 15.0 | 14000 |

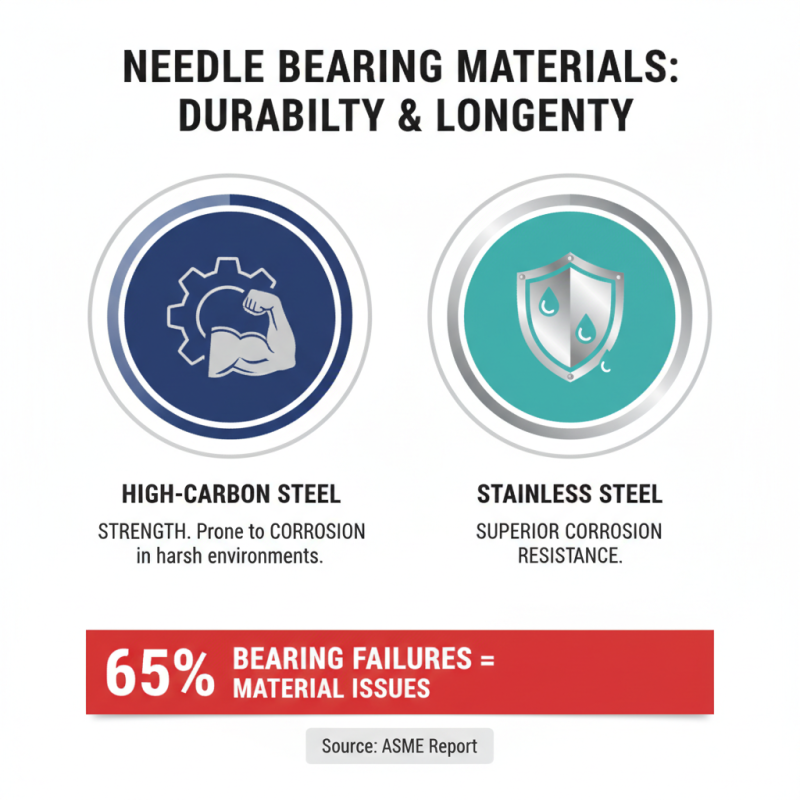

Material Considerations for Durability and Longevity

When selecting needle bearings, material choice plays a crucial role in durability and longevity. Different materials exhibit varying resistance to wear and corrosion. For instance, high-carbon steel is often favored for its strength. However, it may not perform well in harsh environments. In contrast, stainless steel offers superior resistance to corrosion. A report by the American Society of Mechanical Engineers highlights that up to 65% of bearing failures result from material issues.

Polymer-based needle bearings are also gaining traction. They are lightweight and can operate in environments where metal bearings fail. Researchers found that polymer bearings exhibit a 30% longer life in certain applications. Yet, they may not withstand heavy loads as effectively as metal options. This trade-off is essential to consider.

In many cases, testing and analysis reveal surprising outcomes. For example, a bearing deemed suitable in theory may underperform in practical applications. Material choices require careful evaluation. Understanding the specific demands of each project is vital for ensuring bearing performance over time.

Installation Tips and Best Practices for Needle Bearings

Installing needle bearings effectively can be challenging, but a few best practices can simplify the process. Ensure the bearing housing is clean and free from debris before installation. A dirty surface can cause improper fit and premature wear. Use a proper alignment tool to guide the bearing into place. Misalignment can lead to increased friction and malfunction.

During installation, avoid excessive force. Applying too much pressure may cause damage to the bearing or housing. Instead, use gentle taps with a soft hammer or a similar tool. This approach can help ensure an even distribution of pressure. Keep the bearing well-lubricated during this process to facilitate smooth movement.

After installation, regularly check the bearings for any signs of wear or misalignment. This ongoing inspection can prevent unexpected failures. If you notice unusual noise or vibration, consider recalibrating or replacing the bearings. Needle bearings can be complex, and ensuring they are correctly fitted is essential for optimal performance. Reflect on your installation technique; even small changes can make a significant difference.

Needle Bearings Selection Criteria and Performance Metrics

Related Posts

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

-

2025 Top Needle Bearing Trends: What You Need to Know for Optimal Performance

-

Top Benefits of Using Needle Rollers in Modern Machinery Applications

-

The Ultimate Guide to Choosing the Best Bearing Needles in 2025

-

How to Choose the Right Tyre Bearing for Your Vehicle Needs