How to Choose the Right Tyre Bearing for Your Vehicle Needs

Selecting the appropriate Tyre Bearing is crucial for ensuring optimal vehicle performance and safety. According to a report by the International Council on Clean Transportation, improper tyre maintenance and selection can lead to a 20% decrease in fuel efficiency and a significant increase in emissions. Furthermore, the Tire and Rim Association indicates that nearly 40% of vehicle breakdowns are attributed to tyre-related issues, emphasizing the importance of choosing the right bearings for maximum durability and performance.

As vehicles become more advanced, understanding the specific requirements for tyre bearings, such as load capacity, speed ratings, and compatibility with different tyre types, has never been more vital. In this guide, we will explore key considerations to help you make an informed decision when selecting the perfect Tyre Bearing for your specific vehicle needs.

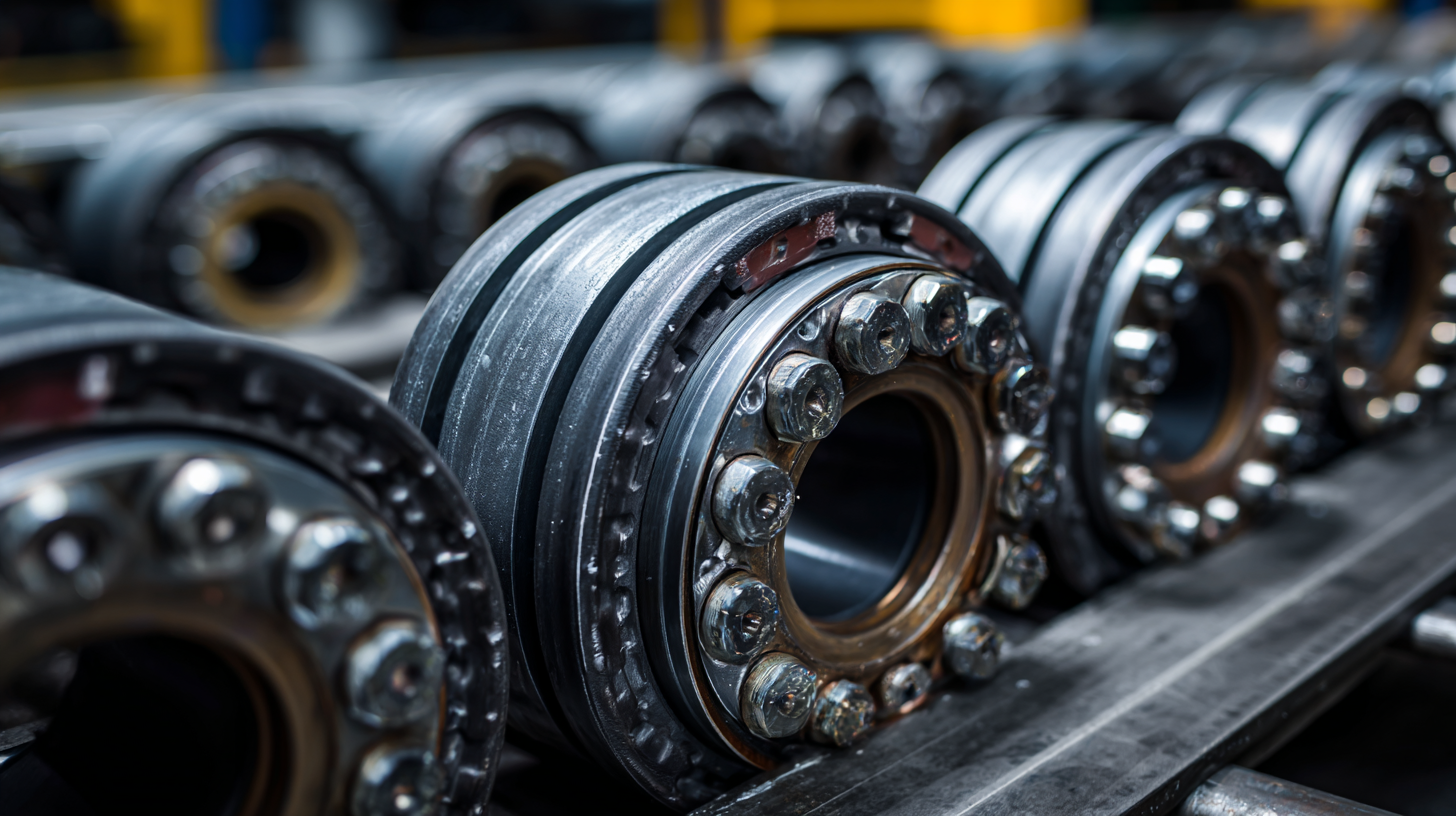

Understanding Different Types of Tyre Bearings and Their Functions

When it comes to choosing the right tyre bearing for your vehicle, understanding the different types and their functions is essential. There are primarily two types of tyre bearings: ball bearings and roller bearings. Ball bearings are designed for light to moderate loads and provide smoother performance due to their circular shape. They are commonly used in passenger vehicles, which require precision and minimal friction for efficient fuel consumption. According to a report by the Automotive Industry Association, nearly 65% of new vehicles utilize ball bearings for their wheel hubs due to their favorable balance of cost and performance.

On the other hand, roller bearings are built to handle heavy loads and provide greater durability, making them ideal for commercial vehicles or off-road applications. They have a higher load capacity and can withstand greater stress, which is crucial for vehicles operating in demanding conditions. The American Society of Mechanical Engineers has noted that in extremely rugged environments, roller bearings can extend the service life of the wheel assembly by up to 40%. Thus, understanding the specific operational requirements of your vehicle is key to selecting the right tyre bearing, ensuring optimal performance and safety on the road.

How to Choose the Right Tyre Bearing for Your Vehicle Needs

| Bearing Type | Material | Load Capacity (kg) | Speed Rating (RPM) | Temperature Range (°C) | Applications |

|---|---|---|---|---|---|

| Ball Bearing | Chrome Steel | 1500 | 12000 | -20 to 120 | Passenger Cars |

| Roller Bearing | Carbon Steel | 2500 | 10000 | -10 to 90 | Light Trucks |

| Tapered Roller Bearing | Alloy Steel | 3000 | 8000 | -20 to 150 | Heavy-Duty Vehicles |

| Spherical Roller Bearing | Boron Steel | 5000 | 6000 | -30 to 100 | Agricultural Vehicles |

| Needle Bearing | Stainless Steel | 800 | 14000 | -20 to 120 | Motorcycles |

Key Factors to Consider When Selecting Tyre Bearings for Vehicles

When selecting tyre bearings for vehicles, several key factors need to be considered to ensure optimal performance and safety. Cost is often the first aspect that comes to mind. Budget constraints can dictate the type of tyre bearings one can purchase, but it's important to balance cost with quality and durability. A study shows that investing in higher-quality bearings often leads to reduced maintenance costs over time and enhances the vehicle's efficiency.

Another crucial factor is the service capabilities of the tyre bearings. This includes understanding the specific driving conditions they will be subjected to, such as off-road terrain or urban environments. Recent advancements in tyre bearing technology emphasize the importance of compatibility with vehicle designs and the ability to withstand high stress and various environmental factors. For example, the introduction of new durable designs that improve fuel-efficiency can significantly affect the overall performance of commercial fleets, where safety and reliability are paramount.

Finally, safety cannot be overlooked. The performance of tyre bearings has a direct impact on vehicle handling and braking efficiency. Studies indicate that the right choice of bearings can improve traction and stability, thus enhancing the overall safety of the vehicle under different operating conditions. In fleet operations, where multiple vehicles are managed, ensuring that each vehicle is equipped with the appropriate bearing can lead to increased operational efficiency and reduced incidents on the road.

Comparative Analysis of Popular Tyre Bearing Brands and Models

When selecting the right tyre bearing for your vehicle, understanding the comparative landscape of popular brands and models is crucial. According to the latest industry report by Market Research Future, the global automotive bearings market is projected to reach $39 billion by 2025, highlighting the increasing demand for high-quality tyre bearings. Notably, brands like SKF, Timken, and NTN have established a strong reputation in the market due to their commitment to innovation and performance. For instance, SKF's recent advancements in lightweight materials have shown a 15% increase in energy efficiency, making them a preferred choice for many vehicle manufacturers.

When selecting the right tyre bearing for your vehicle, understanding the comparative landscape of popular brands and models is crucial. According to the latest industry report by Market Research Future, the global automotive bearings market is projected to reach $39 billion by 2025, highlighting the increasing demand for high-quality tyre bearings. Notably, brands like SKF, Timken, and NTN have established a strong reputation in the market due to their commitment to innovation and performance. For instance, SKF's recent advancements in lightweight materials have shown a 15% increase in energy efficiency, making them a preferred choice for many vehicle manufacturers.

In addition to brand reputation, it is essential to consider specific models. A study by Grand View Research indicates that tapered roller bearings dominate the market, accounting for over 40% of total sales, primarily due to their high load-bearing capacity and durability. The Timken® 30210 model exemplifies this, providing exceptional performance in both passenger and commercial vehicles. Meanwhile, the NTN® 32209 bearing has been favored for its precision engineering and reduced friction, catering well to the demands of modern vehicles. As vehicle technology advances, selecting the right tyre bearing will become increasingly vital in ensuring optimal performance and safety on the road.

Maintenance Tips for Enhancing Tyre Bearing Longevity

Maintaining tyre bearings is critical for ensuring the longevity and safety of your vehicle. Regular inspections should focus on a few key areas: checking for signs of wear and tear, ensuring that bearings are properly lubricated, and monitoring for any unusual noises while driving. It's advisable to adhere to the manufacturer's maintenance schedule, but also to listen to your vehicle; if you notice any grinding or whirring sounds, it may indicate a need for immediate inspection or replacement.

In addition to proactive maintenance, practicing safe loading and driving habits can significantly extend the service life of tyre bearings. Avoiding excessive weight and ensuring that your vehicle is balanced properly can reduce stress on the wheel-end components. Moreover, adhering to proper torque specifications during wheel installations is essential. As tyre technology continues to evolve, staying informed about the latest wheel bearing advancements and employing best practices can help you avoid costly repairs and enhance the performance of your vehicle.

Common Mistakes to Avoid When Choosing Tyre Bearings

Choosing the right tyre bearing for your vehicle is crucial for safety and performance. However, many vehicle owners make common mistakes that can lead to significant issues, including severe accidents caused by bearing failures. A notable risk highlighted by industry experts is the potential for wheel-offs and wheel-related fires, which are often exacerbated by inadequate attention to bearing selection and maintenance. Recent incidents, such as the derailment in East Palestine attributed to a failing wheel bearing, demonstrate the catastrophic consequences these failures can cause.

To avoid these pitfalls, it's essential to pay close attention to the specifications and compatibility of the bearings with your vehicle. Ensure you are selecting high-quality bearings that adhere to industry standards, as subpar components can increase the likelihood of failure. Regular inspections and maintenance are also critical—over 60% of wheel bearing failures occur due to lack of maintenance, according to industry studies.

**Tips:** Always consult with a professional mechanic or a technical expert when in doubt about the appropriate bearings for your vehicle. Consider investing in advanced monitoring systems to detect potential bearing failures early, as proactive measures can significantly decrease the risks of fires or accidents caused by faulty components. Lastly, be aware of the signs of bearing wear, such as unusual noises or vibrations, which can signal a need for immediate replacement.

Tyre Bearing Selection: Common Mistakes and Considerations

Related Posts

-

How to Choose the Right Pillar Bearing for Your Industrial Needs

-

How to Choose the Right Tapped Bearing for Your Application Needs

-

10 Facts About Real Bearing for Optimal Performance in Your Machinery

-

Understanding the Functionality and Benefits of Nup Bearing Types

-

How to Choose the Right Needle Rollers for Your Mechanical Applications

-

10 Essential Tips for Choosing the Perfect Tapped Bearing