2026 Best Needle Bearings for Optimal Performance and Durability?

Needle bearings are crucial components in many industries. Their efficiency can significantly impact machine performance. According to a report from MarketsandMarkets, the global needle bearings market is projected to reach $8.5 billion by 2026. This growth highlights the demand for higher durability and better performance in machinery.

In aerospace and automotive sectors, needle bearings offer low-friction solutions. They allow for a compact design, which is essential for modern engineering. However, choosing the right needle bearing is not straightforward. Factors such as material, surface finish, and lubrication must be considered. A poorly selected bearing can lead to failures, leading to costly downtimes.

Industries must prioritize durability and performance when selecting needle bearings. A study conducted by SKF showed that improper installation can reduce bearing lifespan by 50%. Users need to be aware of these risks. Maintaining optimal performance requires ongoing monitoring and adjustments. Failing to do so can result in long-term issues that effect overall efficiency.

What Are Needle Bearings and Their Applications in Industry?

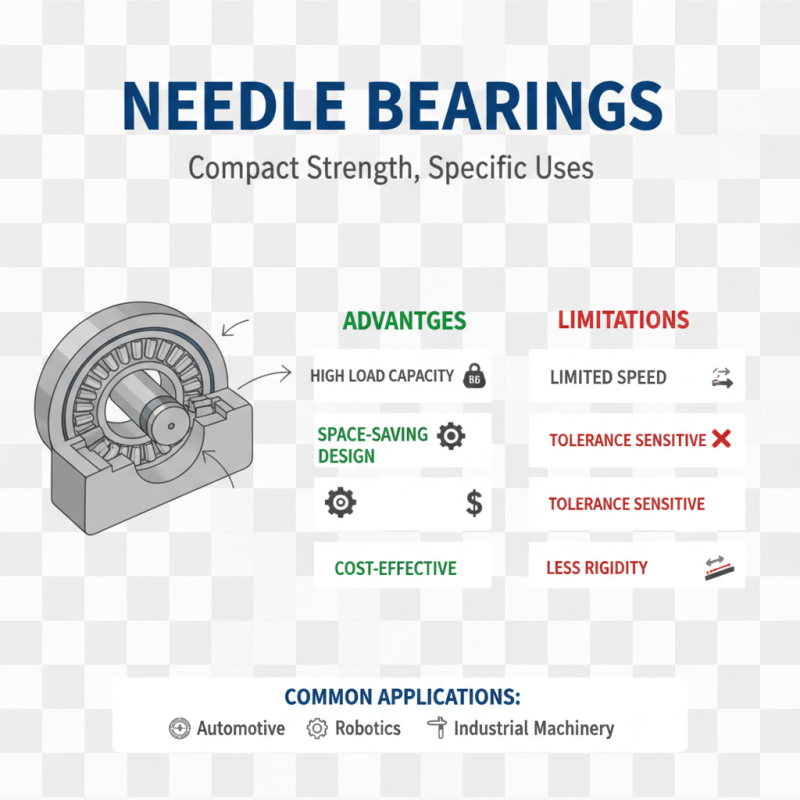

Needle bearings are a specific type of roller bearing. Their design features long, thin cylinders called needles. This shape allows them to handle high radial loads while maintaining a compact size. Industry reports indicate that needle bearings can reduce friction significantly. This makes them ideal for various applications.

In industrial settings, needle bearings are widely used in automotive and manufacturing sectors. They are perfect for applications where space is a concern. For example, they excel in gearboxes and driveshafts. According to a recent study, needle bearings can enhance the efficiency of machinery by up to 15%.

However, challenges exist. Needle bearings have limited axial load capacity. This vulnerability can lead to premature wear under certain conditions. Choosing the right type of needle bearing for specific applications is critical. Misalignment and insufficient lubrication can compromise performance. Therefore, careful consideration is essential when selecting needle bearings for optimal longevity.

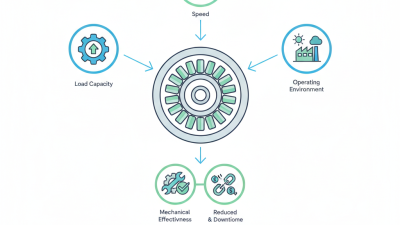

Key Factors Influencing the Performance of Needle Bearings

When considering needle bearings, several key factors play a role in their performance. The material of the bearing impacts its strength and durability. High-quality steel can withstand more load than lower grades. Additionally, the surface finish affects friction levels. A smoother surface will typically yield better efficiency.

Another important aspect is lubrication. Proper lubrication reduces wear and prevents overheating. However, finding the right lubricant can be tricky. Too much lubricant may attract dirt, while too little can lead to failure. These details often get overlooked but are vital for performance.

Installation accuracy also matters greatly. Misalignment can lead to premature wear or even catastrophic failure. This aspect requires careful attention during assembly. Many times, people underestimate how crucial this step is. Each of these factors contributes to the overall functionality of needle bearings, making their consideration essential for optimal performance.

Top Brands and Models of Needle Bearings for 2026

When considering the best needle bearings for 2026, several brands stand out. These brands are known for their innovative designs and quality manufacturing. Their products promise smooth operation and impressive durability. Needle bearings with enhanced surface treatments often deliver improved performance. Many users report longer-lasting results when using these advanced models.

Different applications require specific types of needle bearings. For instance, some designs excel in high-speed scenarios. Others are better suited for heavy loads. It's essential to match the bearing type with its intended use. However, some users find it challenging to choose the ideal model. Many factors can complicate the decision-making process, such as load ratings and temperature limits.

While top models often receive great feedback, not all experiences are positive. Some users may encounter premature wear or noise issues. Regular maintenance is essential but often overlooked. Yet, investing in high-quality needle bearings can mitigate these risks. The right choice can lead to optimal performance and longevity in various applications.

Maintenance Tips for Maximizing the Lifespan of Needle Bearings

Maintaining needle bearings is crucial for optimal performance and longevity. Regular cleaning is essential. Dust and debris can cause significant wear. Use a soft brush to remove dirt. A light solvent can help dissolve sticky residues. Always ensure bearings are dry before re-lubricating.

Lubrication plays a vital role in their lifespan. Applying the right amount of lubricant prevents overheating. Too much grease can trap dirt. Too little leads to increased friction. Ensure you’re using the correct type of lubricant based on your application. Periodic inspection can catch issues early. Look for signs of wear or corrosion. Ignoring small problems often leads to bigger failures.

Storage is another important aspect. Keep needle bearings in a clean, dry place. Extreme temperatures can affect their integrity. If they sit unused for long, consider periodic rotation to prevent flat spots. Recognizing these maintenance steps can dramatically extend the life of these small yet essential components. Each small action contributes to better performance. Missing just one step can lead to larger failures down the line.

2026 Best Needle Bearings Performance Analysis

Comparative Analysis: Needle Bearings vs. Other Bearing Types

Needle bearings are gaining popularity in various applications. Their design allows for high load capacities in compact spaces. This makes them a favorable choice for many mechanical systems. However, they do have limitations compared to other bearing types.

When compared to ball bearings, needle bearings offer a distinct advantage in space efficiency. They are thinner and lighter, which can be crucial in limited spaces. Yet, they may lack the load distribution properties that ball bearings provide. This can lead to premature wear in high-stress environments.

Another option is sleeve bearings. These provide excellent performance in specific conditions. They are often quieter and can handle shock loads well. However, they usually require more lubrication, which can complicate maintenance. Every bearing type has its pros and cons. Understanding these differences is key to optimal performance.

Related Posts

-

Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

-

2025 Top Needle Bearing Trends: What You Need to Know for Optimal Performance

-

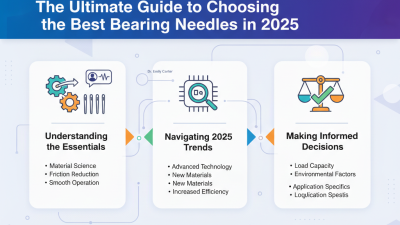

The Ultimate Guide to Choosing the Best Bearing Needles in 2025

-

2026 How to Choose the Right Needle Bearings for Your Projects?

-

2026 Top Needle Bearings Options and Their Benefits?

-

Revolutionizing Motion: How Stick Bearings Enhance Efficiency in Modern Machinery