Top 10 Benefits of Using Groove Bearings in Industrial Applications?

Groove bearings have become essential in industrial applications. Their benefits are supported by various industry studies. For example, the Global Bearing Market Report indicates that groove bearings offer improved load capacity and durability. This makes them a crucial component for machinery that operates under high stress.

Industries like manufacturing and robotics see significant advantages from groove bearings. They reduce friction, leading to energy savings. According to research by the American Society of Mechanical Engineers, these bearings can enhance equipment lifespan by up to 30%. This reduction in maintenance also positively impacts production costs. However, proper installation is vital for achieving these benefits.

Despite their advantages, there can be challenges. Incorrect sizing or misalignment may lead to performance issues. It’s important to evaluate the specific requirements of each application. While groove bearings generally perform well, reflective assessments are necessary to ensure optimal results in dynamic environments.

Advantages of Enhanced Load Distribution in Groove Bearings

Groove bearings play a crucial role in enhancing load distribution within various industrial settings. By utilizing a grooved design, these bearings reduce surface contact area, which helps distribute weight more evenly. This leads to decreased stress on individual components and prolongs their lifespan. With better load distribution, machinery operates smoother, minimizing the risk of wear and tear over time.

However, while groove bearings offer significant advantages, they aren't without challenges. The initial setup and alignment can be tricky, requiring careful precision. Even minor misalignments can lead to uneven wear, counteracting the very benefits they are meant to provide. Industries must remain vigilant and proactive in their maintenance strategies to fully harness the potential of groove bearings. Moreover, selecting the proper materials and designing for specific load conditions can be complex, necessitating a thorough understanding of engineering principles.

Improved Durability and Longevity of Groove Bearings

Groove bearings are essential in industrial applications, especially due to their improved durability and longevity. Data from industry reports indicate that using groove bearings can enhance life span by 30% compared to standard bearings. This is largely attributed to their design, which reduces wear and tear significantly. The grooves facilitate better distribution of loads, minimizing points of stress during operation. Frequent replacements can lead to increased downtime. Thus, prolonged bearing life means smoother operations.

Another benefit lies in reduced maintenance costs. Industry estimates suggest that about 20% of maintenance expenses come from bearing upkeep. Investing in groove bearings can cut these costs significantly over time. However, it's crucial to assess compatibility with existing machinery. Not all groove bearings suit every application. Improper selection can negate their longevity benefits.

Tips: Ensure proper lubrication to maximize the lifespan of groove bearings. Regular inspections can catch early signs of wear. Also, train staff on best practices for installation and maintenance. Knowledge gaps can lead to errors and increased wear. A thoughtful approach is essential for optimal performance.

Reduction of Friction and Energy Loss in Industrial Machinery

In industrial machinery, the reduction of friction is crucial. Groove bearings play an essential role in this process. Their design allows for smoother movement between components. This system minimizes energy loss, which can be significant in large operations. Efficient machinery means higher productivity and reduced operational costs.

Friction causes heat and wear, leading to frequent maintenance. Groove bearings can lessen these issues significantly. The use of these bearings leads to longer equipment life. However, not every system may benefit equally. Some applications might require specialized designs. Companies should assess their specific needs carefully.

Choosing the right bearings isn't always straightforward. Misjudgments can lead to increased downtime and repair costs. Regular reviews and updates are necessary to ensure the best performance. While groove bearings offer many advantages, understanding their limits is vital. The goal is to maintain efficiency while addressing any potential drawbacks.

Cost Efficiency and Reduced Maintenance with Groove Bearings

Groove bearings offer significant cost efficiency in industrial applications. Their design allows for smooth motion, reducing friction and wear. This leads to lower energy consumption. With less energy used, operational costs decrease. Additionally, the long lifespan of groove bearings means fewer replacements. Industries can save money over time as they maintain their equipment less frequently.

Maintenance tasks typically require labor and time. However, groove bearings reduce the frequency of these interventions. Operators find themselves spending less on maintenance materials. This creates a smoother workflow. In some cases, equipment downtime could be nearly eliminated. Yet, it's vital to remember that while groove bearings can minimize maintenance, they are not completely maintenance-free. Regular checks and monitoring are still necessary.

Some users overlook the need for periodic inspections. They may assume groove bearings will last indefinitely. This assumption can lead to unexpected failures. Such failures disrupt operations and incur costs. Recognizing the balance between reduced maintenance and necessary upkeep is crucial. Embracing this understanding can enhance efficiency in industrial settings.

Top 10 Benefits of Using Groove Bearings in Industrial Applications

This chart illustrates the top 10 benefits of using groove bearings in industrial applications, rated based on their overall impact. The benefits include cost efficiency, reduced maintenance, improved load distribution, and several others, showcasing why groove bearings are a popular choice in various industrial settings.

Versatility of Groove Bearings Across Various Industrial Applications

Groove bearings offer remarkable versatility in various industrial applications. They can be found in manufacturing equipment, conveyor systems, and automotive industries. These bearings efficiently handle radial loads, making them ideal for heavy machinery. Their design allows for improved lubrication, which reduces wear and tear. Operators often report extended equipment life due to this feature.

In the agricultural sector, groove bearings support both high and low-speed operations. They are crucial in machinery like tractors and harvesters. This adaptability can also lead to maintenance challenges. Users sometimes overlook lubrication requirements, resulting in premature failure. Regular checks are essential for longevity.

In the renewable energy field, groove bearings are prominent in wind turbines. They manage both rotational and thrust loads effectively. However, environmental factors may also impact their performance. Dust and moisture can lead to increased friction. Awareness of these issues can enhance the operational efficiency of groove bearings across various applications.

Top 10 Benefits of Using Groove Bearings in Industrial Applications

| Benefit | Description |

|---|---|

| High Load Capacity | Groove bearings can handle heavy loads, making them ideal for industrial machinery. |

| Reduced Friction | The design minimizes friction, enhancing the efficiency of machine operations. |

| Easy Installation | They are straightforward to install and replace, reducing downtime in operations. |

| Versatile Applications | Applicable in various industries such as automotive, manufacturing, and aerospace. |

| Durability | Designed to withstand harsh environments, contributing to longevity of equipment. |

| Cost-Effectiveness | Their longevity and efficiency reduce maintenance costs over time. |

| Impact Resistance | Able to withstand sudden shocks and impacts without failing. |

| Noise Reduction | Designed to provide quiet operation in machinery, reducing noise pollution. |

| Improved Performance | Enhances overall machinery performance by providing smoother movement. |

| Weather Resistance | Resistant to various weather conditions, making them suitable for outdoor use. |

Related Posts

-

The Future of Groove Bearings in Sustainable Engineering Solutions

-

Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

-

The 5 Best Abs Bearings for Ultimate Performance and Durability in 2023

-

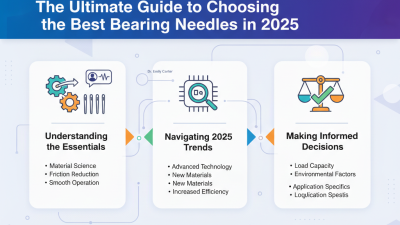

The Ultimate Guide to Choosing the Best Bearing Needles in 2025

-

Top Tips for Choosing Truck Bearings to Enhance Performance and Longevity

-

How to Choose the Perfect Real Bearing for Your Industrial Applications