2025 Top Needle Bearing Trends: What You Need to Know for Optimal Performance

In the ever-evolving landscape of mechanical engineering, the role of needle bearings has become increasingly significant. As a crucial component in reducing friction and facilitating smooth motion between moving parts, needle bearings are integral to the performance and longevity of various machinery. Understanding the latest trends surrounding needle bearing technology is essential for engineers and manufacturers aiming to enhance operational efficiency and reliability in their designs.

As we look toward 2025, several key trends are emerging that are poised to reshape the needle bearing industry. From advancements in materials and manufacturing processes to innovative design approaches, these developments promise to improve performance and durability. Additionally, an increasing focus on sustainability and eco-friendly practices within the manufacturing sector is driving the evolution of needle bearing solutions. This article will explore these trends and provide vital insights that professionals need to consider for optimal performance and sustained competitiveness in their respective fields.

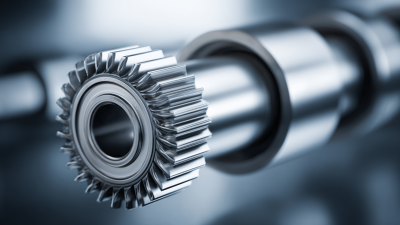

Overview of Needle Bearings and Their Importance in Modern Applications

Needle bearings are essential components in modern machinery, providing a unique solution for applications requiring high load capacity in a compact design. Their slender shape allows them to accommodate heavy radial loads while minimizing friction, making them ideal for situations where space is limited. This design also contributes to the efficiency and longevity of the equipment they are part of, making needle bearings crucial in sectors such as automotive, aerospace, and robotics.

In addition to their load-bearing capabilities, needle bearings enhance precision and performance in mechanical assemblies. They facilitate smooth motion and reduce wear on interacting parts, which is vital for applications like electric motors, gearboxes, and conveyors. As industries continue to innovate, the demand for lightweight and high-performance components like needle bearings is expected to increase, driving advancements in material science and manufacturing techniques. By understanding their significance, engineers and designers can leverage needle bearings to optimize performance and reliability in various applications.

2025 Top Needle Bearing Trends: Performance Metrics

This chart illustrates the projected performance metrics of needle bearings in various applications by 2025. The data highlights the expected advancements in efficiency, durability, and load capacity, which are crucial for optimizing performance in modern machinery.

Key Trends in Needle Bearing Technology for 2025 and Beyond

As we look towards 2025, several key trends in needle bearing technology are emerging that can significantly enhance performance across various applications. One major trend is the increasing adoption of advanced materials, such as polymers and composites, which offer improved resistance to wear and corrosion. These materials not only extend the life of needle bearings but also allow for lighter designs, making them more suitable for industries focused on energy efficiency and weight reduction.

Another notable trend is the integration of smart technology into needle bearings. With the rise of the Internet of Things (IoT), manufacturers are developing needle bearings equipped with sensors that monitor operational conditions in real-time. This allows for predictive maintenance, thereby minimizing downtime and enhancing overall machinery efficiency. Industries are increasingly recognizing the benefits of this technology, as it leads to enhanced reliability and reduces the risk of unexpected failures.

**Tips:** To maximize the performance of needle bearings in your application, regularly monitor operating conditions such as temperature and load. Furthermore, ensure proper lubrication to reduce friction and wear, as this will help maintain the longevity of the bearings. Lastly, stay informed about advancements in needle bearing technology to take advantage of innovations that can improve your equipment's efficiency.

2025 Top Needle Bearing Trends: What You Need to Know for Optimal Performance

| Trend | Description | Impact on Performance | Future Outlook |

|---|---|---|---|

| Advanced Materials | Use of high-strength, lightweight materials to enhance durability. | Higher load capacity and longevity of bearings. | Increased adoption in aerospace and automotive industries. |

| Miniaturization | Development of smaller and thinner needle bearings for compact designs. | Facilitates design flexibility and integration into tight spaces. | Growing demand in consumer electronics and medical devices. |

| Smart Bearing Technology | Integration of sensors for real-time monitoring of performance. | Enhanced predictive maintenance and reduced downtime. | Increased focus on IoT in manufacturing processes. |

| Eco-Friendly Manufacturing | Sustainable practices in production to reduce environmental impact. | Improves corporate responsibility and appeals to eco-conscious consumers. | Support for green regulations and market demand for sustainable products. |

| Increased Load Capacities | Enhancements in design to support greater loads without failure. | Improves performance in heavy machinery and automotive applications. | Future innovations aimed at exceeding current load standards. |

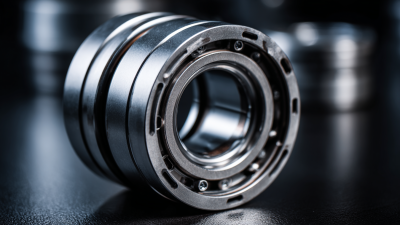

Materials and Manufacturing Innovations in Needle Bearings

In recent years, the needle bearing industry has witnessed significant advancements in materials and manufacturing processes, which are essential to enhance performance and reliability. The introduction of advanced materials like carbon fiber composites and ceramic blends has revolutionized the functionality of needle bearings. According to a recent market analysis by Grand View Research, the demand for high-performance bearings is expected to grow at a compound annual growth rate (CAGR) of approximately 5.4% from 2023 to 2030. These new materials not only improve load capacity but also reduce wear and increase the overall lifespan of the bearings, leading to reduced operational costs across various applications.

Manufacturing innovations, particularly in precision machining and additive manufacturing, have also played a crucial role in the evolution of needle bearings. Data from a report by MarketsandMarkets indicates that the global needle bearing market is anticipated to reach USD 3.1 billion by 2025, driven largely by these technological advancements. Techniques such as 3D printing allow for the production of complex geometries that were previously impossible with traditional methods, enhancing lubrication efficiency and thermal performance. This shift towards innovative manufacturing processes ensures that needle bearings meet the increasing demands for efficiency and durability in modern engineering applications.

Factors Influencing Needle Bearing Performance and Longevity

Needle bearings are essential components in various mechanical applications, and their performance and longevity are influenced by several critical factors. One of the foremost aspects is the quality of the materials used in manufacturing these bearings. Recent reports indicate that the use of high-alloy steels can enhance the fatigue strength of needle bearings by up to 30%, leading to a significant increase in service life under heavy loads. Additionally, advancements in surface treatments, such as nitride and hardening processes, have been shown to reduce wear rates by as much as 25%, further extending the operational lifespan of these bearings.

Another significant factor affecting needle bearing performance is the lubrication regime employed during operation. According to industry studies, proper lubrication can reduce friction by approximately 40%, which not only improves efficiency but also minimizes thermal buildup, a common cause of premature failure. Furthermore, the selection of the right lubricant viscosity is crucial, as improper viscosity can lead to inadequate film formation and increased risk of wear. The implementation of advanced lubrication monitoring systems can help predict maintenance needs and ensure optimal lubrication conditions, thus enhancing the reliability and durability of needle bearings across various applications.

Future Challenges and Opportunities in the Needle Bearing Market

The needle bearing market is poised for significant changes as we approach 2025. As industries evolve, the challenges faced by manufacturers will become more pronounced. Key issues such as material scarcity, sustainability demands, and the need for precision engineering will influence production methods. Moreover, technological advancements will require needle bearings to perform under increasingly demanding conditions, pushing the envelope on durability and efficiency.

To navigate these challenges, companies can adopt proactive strategies. **Tip:** Invest in research and development to explore alternative materials that enhance performance while adhering to sustainability standards. Establishing strong partnerships with suppliers who prioritize eco-friendly practices can also streamline the production process and reduce waste.

Meanwhile, the opportunities in the needle bearing sector are equally promising. With the rise of electric vehicles and automation, the demand for high-performing bearings is surging. This creates a space for innovation and the development of specialized products that cater to these emerging markets. **Tip:** Focus on customization and adaptability in product offerings, ensuring that your needle bearings can meet the specific needs of various applications, which will position your business favorably against competitors.

Related Posts

-

Understanding the Advantages of Needle Bearings for Innovative Engineering Solutions

-

Understanding Groove Bearings: Essential Insights for Enhanced Mechanical Efficiency

-

What is Tapped Bearing and How Does It Enhance Mechanical Performance

-

How to Choose the Right Tapped Bearing for Your Application Needs

-

How to Choose the Right Pillow Bearing for Your Industrial Applications

-

2025 How to Choose the Best Tire Bearings for Optimal Vehicle Performance